Magnetic field type single-anode-and-cathode electrophoretic coating equipment

A technology of cathodic electrophoresis and coating equipment, applied in electrolytic coatings, electrophoretic plating, coatings, etc., can solve the problems of poor electrophoretic deposition effect and poor uniformity of electrophoretic deposited coatings, and achieve improved effect, quality and convenience. , the effect of improving the density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

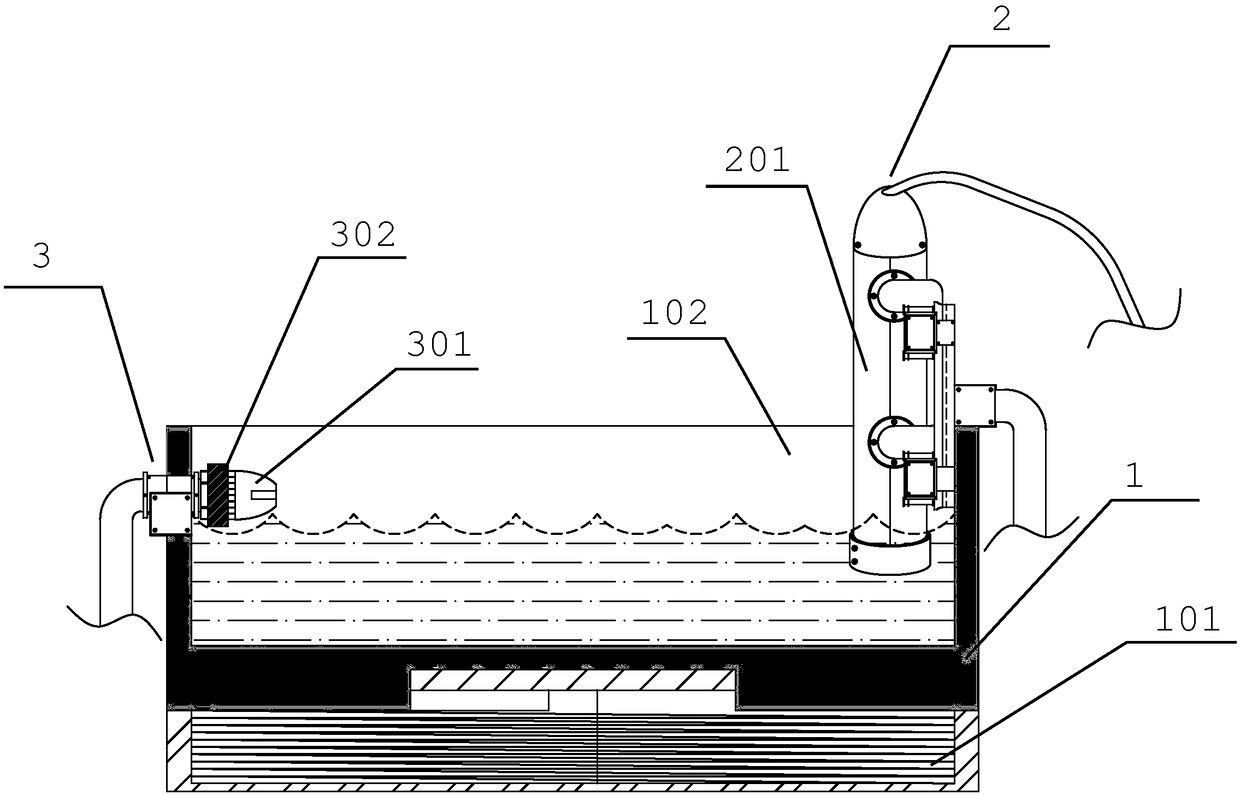

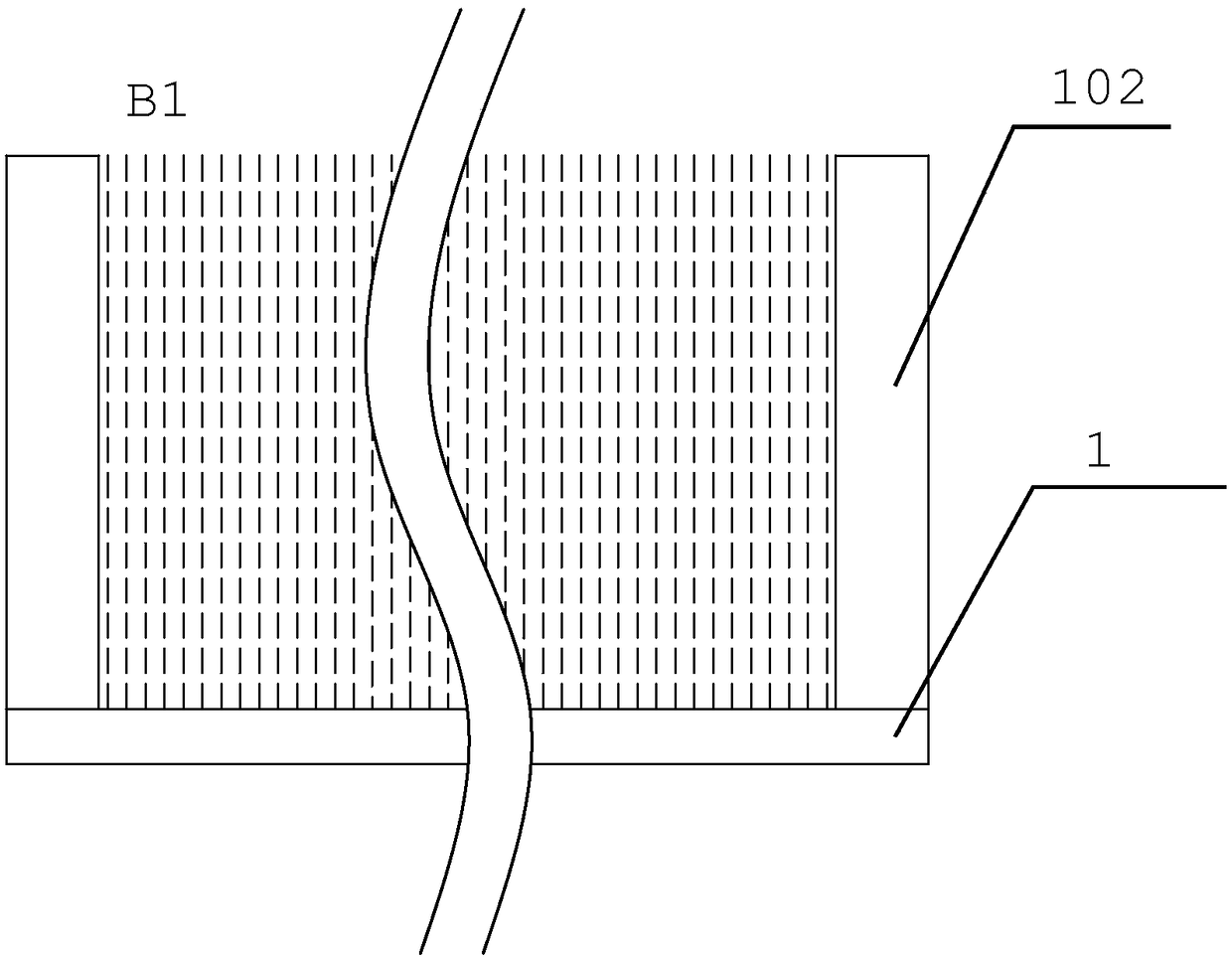

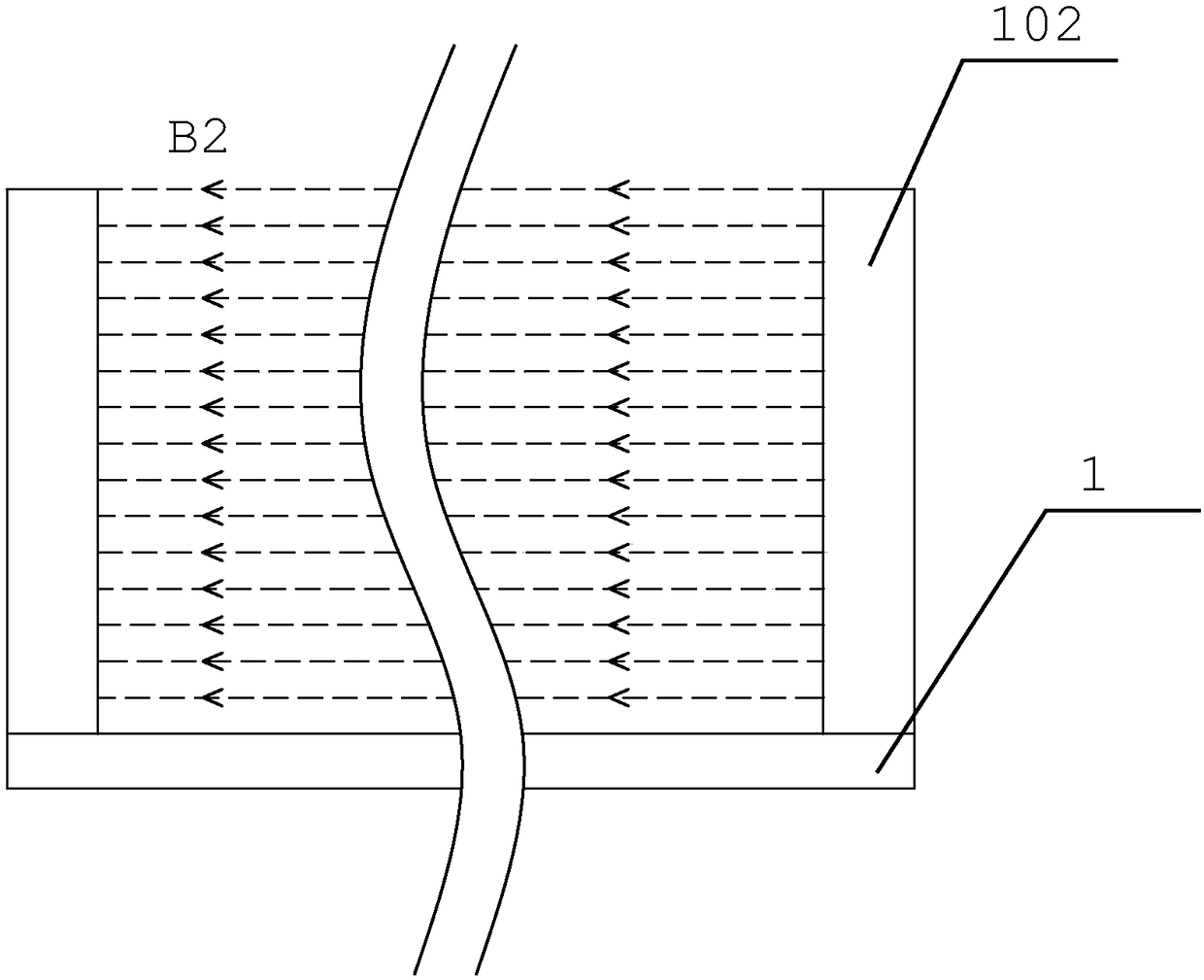

[0039] Such as figure 1 A magnetic field type single anode cathodic electrophoretic coating equipment shown includes an electrophoresis tank 1 and a cathode structure 3 and an anode structure 2 oppositely arranged in the electrophoresis tank 1, wherein the cathode structure 3 is provided with a steering mechanism 302, and the front end of the steering mechanism 302 is The clamping part 301 is fixedly connected, the anode structure 2 includes an anode column 201 for providing charged particles required for electrophoresis, the bottom of the electrophoresis tank 1 is provided with a first magnetic field generating mechanism 101, and the opposite side walls of the electrophoresis tank 1 are provided with second In the magnetic field generating mechanism 102, the two side walls of the second magnetic field generating mechanism 102 are interlaced with the two side walls of the cathode and anode. And ordinary cathodic electrophoretic coating equipment routinely equipped with auxiliary

Embodiment 2

[0052] Such as figure 1 A magnetic field type single anode cathodic electrophoretic coating equipment shown includes an electrophoresis tank 1 and a cathode structure 3 and an anode structure 2 oppositely arranged in the electrophoresis tank 1, wherein the cathode structure 3 is provided with a steering mechanism 302, and the front end of the steering mechanism 302 is The clamping part 301 is fixedly connected, the anode structure 2 includes an anode column 201 for providing charged particles required for electrophoresis, the bottom of the electrophoresis tank 1 is provided with a first magnetic field generating mechanism 101, and the opposite side walls of the electrophoresis tank 1 are provided with second In the magnetic field generating mechanism 102, the two side walls of the second magnetic field generating mechanism 102 are interlaced with the two side walls of the cathode and anode. And ordinary cathodic electrophoretic coating equipment routinely equipped with auxiliary

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap