Double-glass assembly and battery piece arrangement structure

A double-glass module and cell technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of large changes in light intensity, affecting the growth of crops, wasting glass, etc., to improve light transmittance, improve light uniformity, The effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

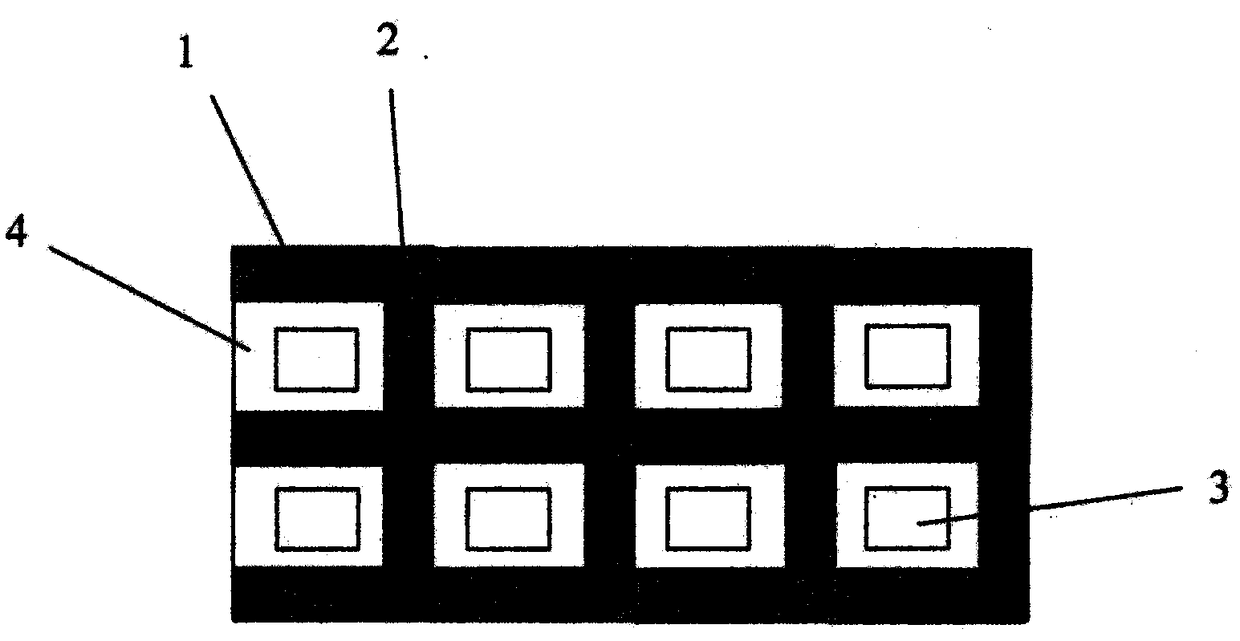

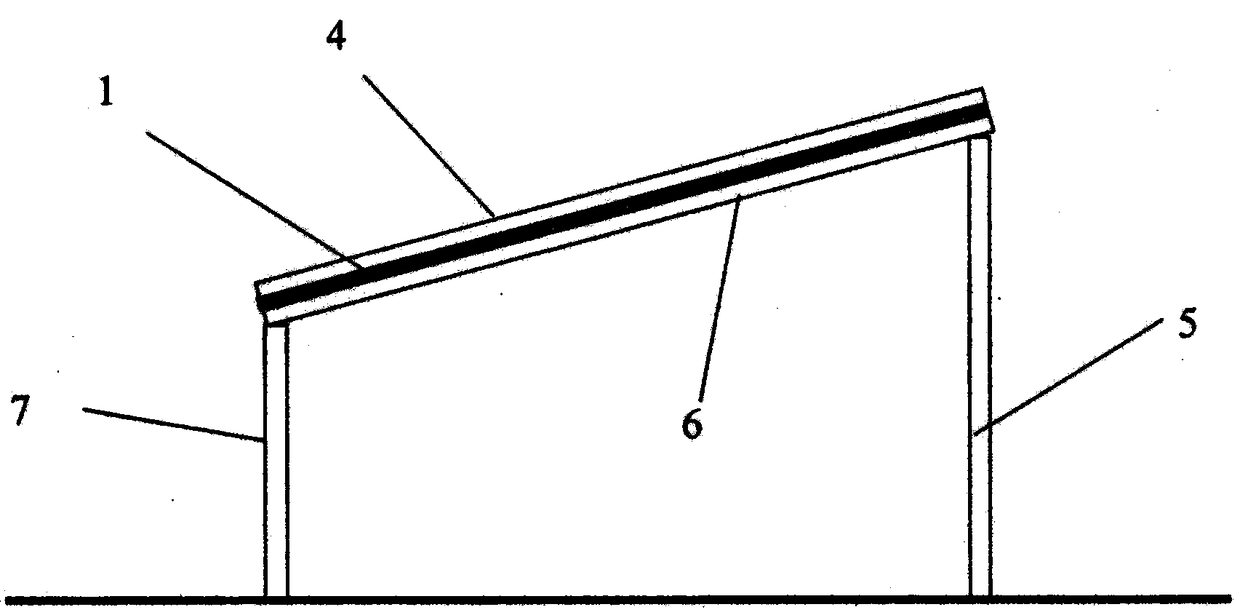

[0012] As in the accompanying drawings figure 1 , figure 2 As shown, a double-glass module and its cell installation structure include a first photovoltaic cell 1, a second photovoltaic cell 2, a transparent upper cover 4, a transparent back plate 6, a first pillar 5, and a second pillar 7. The first photovoltaic cells 1 and the second photovoltaic cells 2 are arranged between the transparent upper cover plate 4 and the transparent back plate 6. The first photovoltaic cells 1 are arranged in several rows, and the distance between adjacent rows is the same. Each row Adjacent first photovoltaic cells 1 are adjacent to each other, and the distance between adjacent rows is equal to the size of the long side of the second photovoltaic cells 2. The second photovoltaic cells 2 are arranged in several rows at equal intervals and placed on the first photovoltaic cells 1. Between several rows arranged, the long side of the second photovoltaic cells 2 is perpendicular to several rows of c

specific Embodiment approach 2

[0018] 1. As shown in the accompanying drawings of the manual figure 1 , figure 2 As shown, the arrangement structure of the double-glass module and its cells also includes several holes 3, and several first photovoltaic cells 1 of the same size and several second photovoltaic cells 2 of the same size constitute several size For the same square transparent areas, there is a hole 3 in the middle of each square transparent area.

[0019] According to the requirements of the above-mentioned arrangement method of photovoltaic cells, photovoltaic cell manufacturers can manufacture the double-glass modules, and the manufacturing technology of double-glass modules is currently very mature.

[0020] Double-glass components are generally installed at a certain inclination angle to the ground, and the specific inclination angle is calculated and determined according to the local geographical location. There are many calculation methods in this area and they are very mature. It is a well-

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap