Feeding machine with weighing system

A weighing system and feeder technology, applied in the field of feeders, can solve problems such as errors in hand measurement, death, affecting the growth of abalone, and achieve the effects of avoiding large errors, accurate feeding amount, and flexible and convenient selection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present application will be further described in detail through the following embodiments in conjunction with the accompanying drawings. Apparently, the described embodiments are only part of the embodiments of the present application.

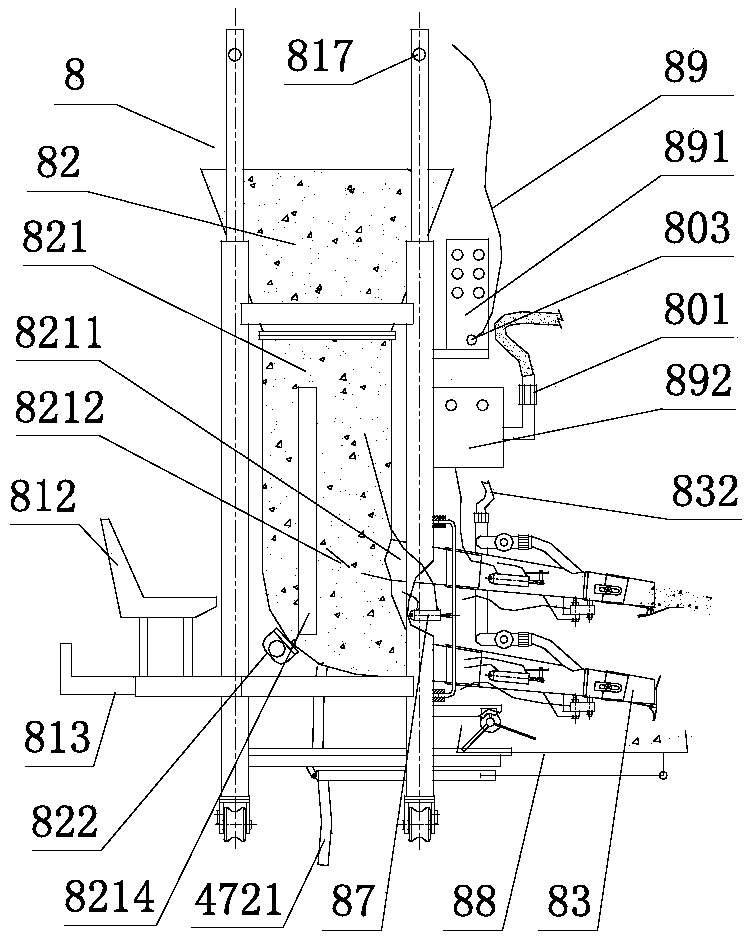

[0033] Such as image 3 , Figure 4 , Figure 5 As shown, it is a front view, a side view, and a partial enlarged view of a feeder with a weighing system according to the first embodiment of the present application. The feeder 8 includes a frame 81, a silo 82, and a hopper 821 , material injection pipe 83, material injection pipe lateral adjustment device 87, leaking material receiving device 88, weighing system 80, high-pressure gas distribution system 08, water flushing system 47, control system 89, and the frame 81 includes four columns 811 and the framework that cross bar constitutes, and the frame is provided with console 812 and storage platform 813, described frame below is provided with moving wheel

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap