Underwater suspension cluster type manifold system with flexible jumper tubes inside

A technology of manifold system and jumper pipe, applied in the field of underwater production system, can solve the problems of unreusable underwater infrastructure installation cost, expensive, difficult to discard and recycle, etc., to reduce the force and bending moment, and avoid utilization , the effect of not easy to rollover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

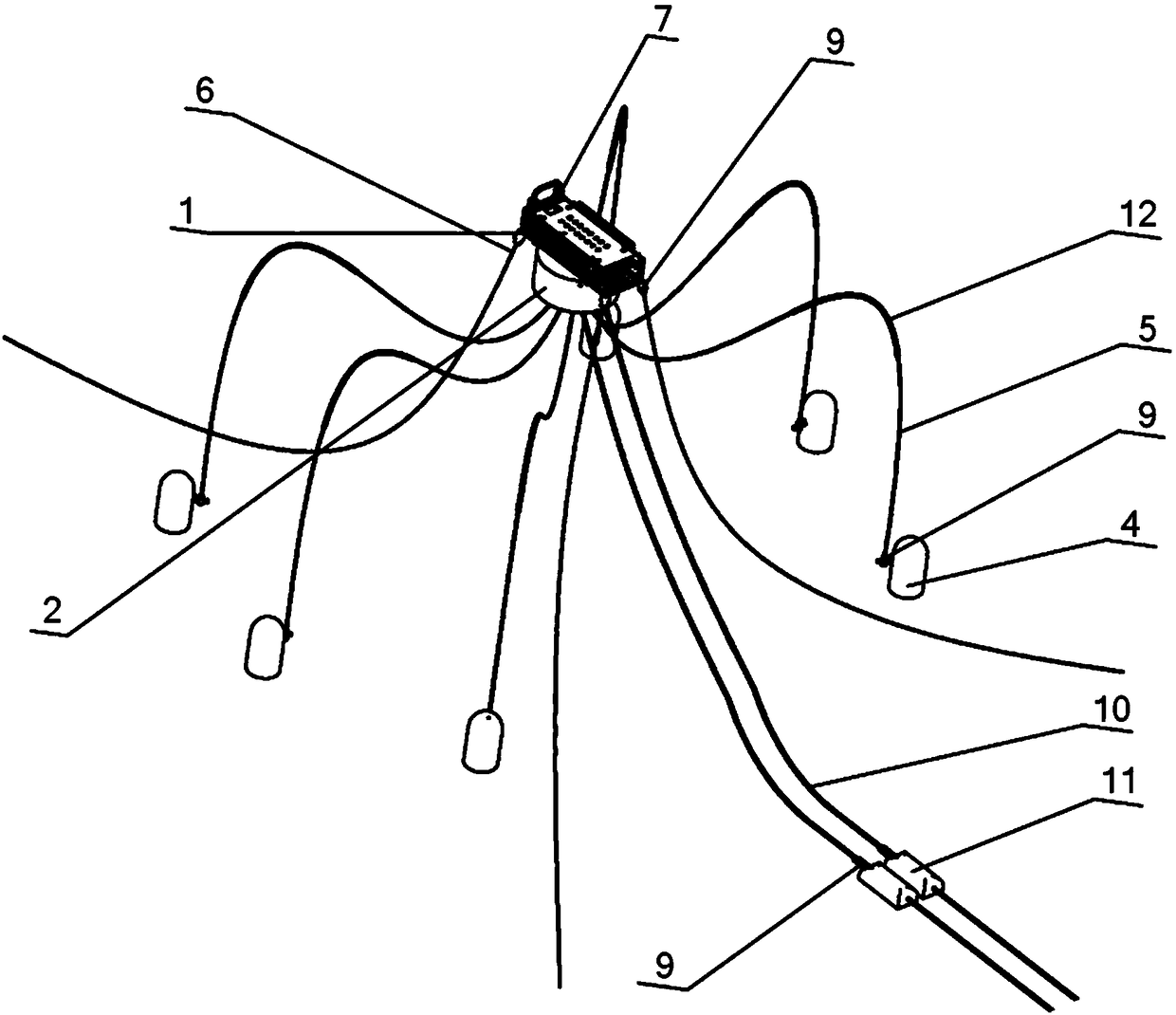

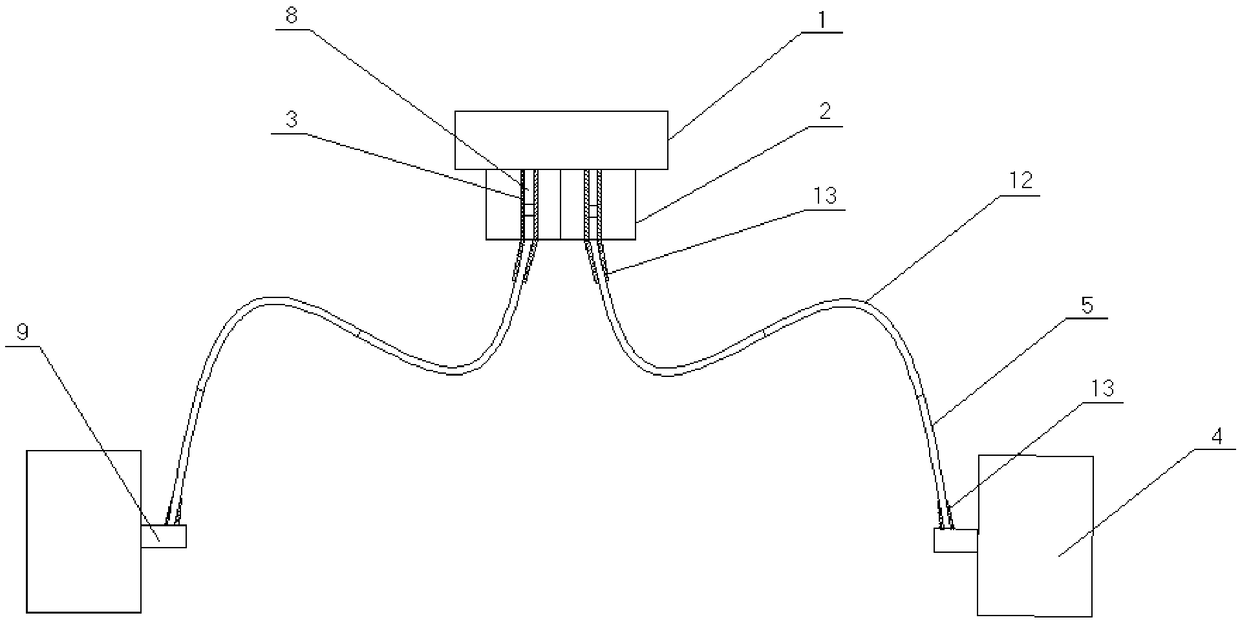

[0019] like figure 1 , figure 2 As shown, the underwater floating cluster manifold system provided by the present invention includes a cluster manifold main body 1, a buoy 2, an I-tube 3 (I-type channel), a deep water functional cabin 4, a flexible jumper 5 and a mooring cable 6. The buoy 2 is arranged at the bottom of the main body of the cluster manifold 1, so that the main body of the cluster manifold 1 is suspended underwater at a certain height from the seabed. A plurality of I-tubes 3 are arranged in the buoy 2 , and manifold branch pipes 8 on the production hub 7 are respectively connected to the I-tubes in the buoy 2 . The far ends of multiple f

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap