All-silicon mesoporous material, preparation method thereof and application thereof in rearrangement reaction

A mesoporous material and rearrangement reaction technology, applied in the preparation of lactams, chemical instruments and methods, silicon oxide and other directions, can solve the problems of long hydrolysis time, low synthesis efficiency, etc., and achieve improved pore structure, improved synthesis efficiency, Effects of high cyclohexanone oxime conversion and caprolactam selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

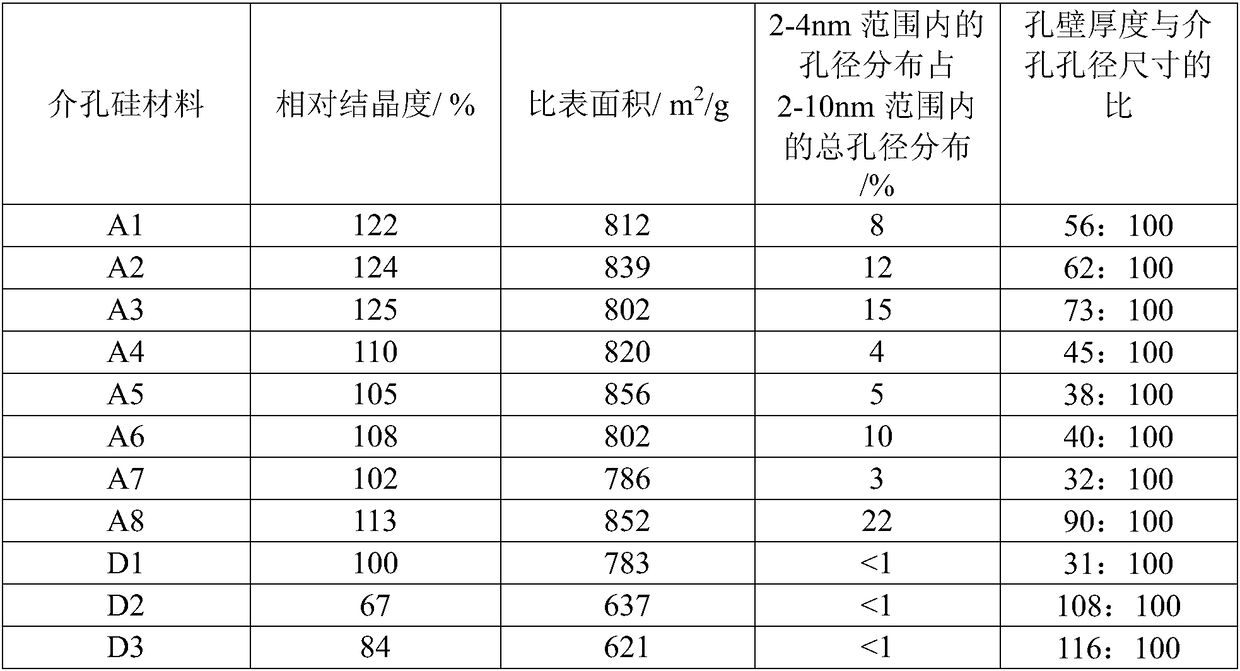

Examples

Example Embodiment

[0019] The second aspect of the present invention provides a method for preparing an all-silicon mesoporous material, the method comprising:

[0020] (1) Mix acid, surfactant and organosilicon source to SiO 2 Calculated organic silicon source, with H + The molar ratio of the amount of the acid, the surfactant and the water is 100:0.1-50:0.01-20:200-50000; a mixture with the hydrolysis rate of the organosilicon source being 20% by weight or less is obtained;

[0021] (2) Under airtight conditions, subject the mixture obtained in step (1) to crystallization treatment; wherein, the conditions of the crystallization treatment include: a temperature of 60-190°C and a time of 4-100h;

[0022] (3) Solid-liquid separation is performed on the product after the crystallization treatment, and the solid phase obtained by the solid-liquid separation is calcined.

[0023] According to the present invention, the preparation method of the all-silicon mesoporous material of the present invention can obt

Example Embodiment

[0048] Example 1

[0049] This embodiment is used to illustrate the all-silicon mesoporous material of the present invention and its preparation method.

[0050] First add 50g of ethyl orthosilicate and cocamidopropyl dimethyl tertiary amine (purchased from Huainan Dejun Fine Chemical Co., Ltd.) into the aqueous solution of hydrochloric acid and mix (mix for about 2 minutes at 20°C), in which ethyl orthosilicate The molar ratio of ester, hydrochloric acid, cocamidopropyl dimethyl tertiary amine and water is 1:1:1:1000, and the organic silicate is SiO 2 Calculated, acid source in H + Calculate, and immediately transfer the resulting mixture (hydrolysis rate of organosilicon source below 5%) into a sealed reactor for hydrothermal crystallization at 120°C for 10 hours, filter, wash, and dry the resulting crystalline product at 110°C for 120 minutes, then It was fired at 550°C for 3 hours to obtain mesoporous silicon material A1.

[0051] After testing, its XRD crystal phase has diffractio

Example Embodiment

[0052] Example 2

[0053] This embodiment is used to illustrate the all-silicon mesoporous material of the present invention and its preparation method.

[0054] First add 50g of ethyl orthosilicate and lauramidopropyl dimethyl tertiary amine (purchased from Huainan Dejun Fine Chemical Co., Ltd.) into the aqueous solution of acetic acid and mix (mix for about 1 min at 20°C), in which ethyl orthosilicate The molar ratio of acetic acid, lauramide propyl dimethyl tertiary amine and water is 1:1.5:1.5:800, and the organic silicate is SiO 2 Calculated, acid source in H + Calculate, and immediately transfer the obtained mixture (hydrolysis rate of organosilicon source below 3%) into a sealed reaction kettle for hydrothermal crystallization at 140°C for 12h, filter, wash, and dry at 110°C for 100min, then It is fired at 560°C for 4h to obtain mesoporous silicon material A2.

[0055] After testing, its XRD crystal phase has diffraction peaks at small angles, namely 2θ near 0.8°, 1.5° and 1.7°,

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap