Vertical wind direction adjusting bracket

A technology of wind direction adjustment and tripod support, applied in the field of supports, can solve problems such as unfavorable normal operation of equipment, limited work efficiency, and inability to adjust the wind direction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

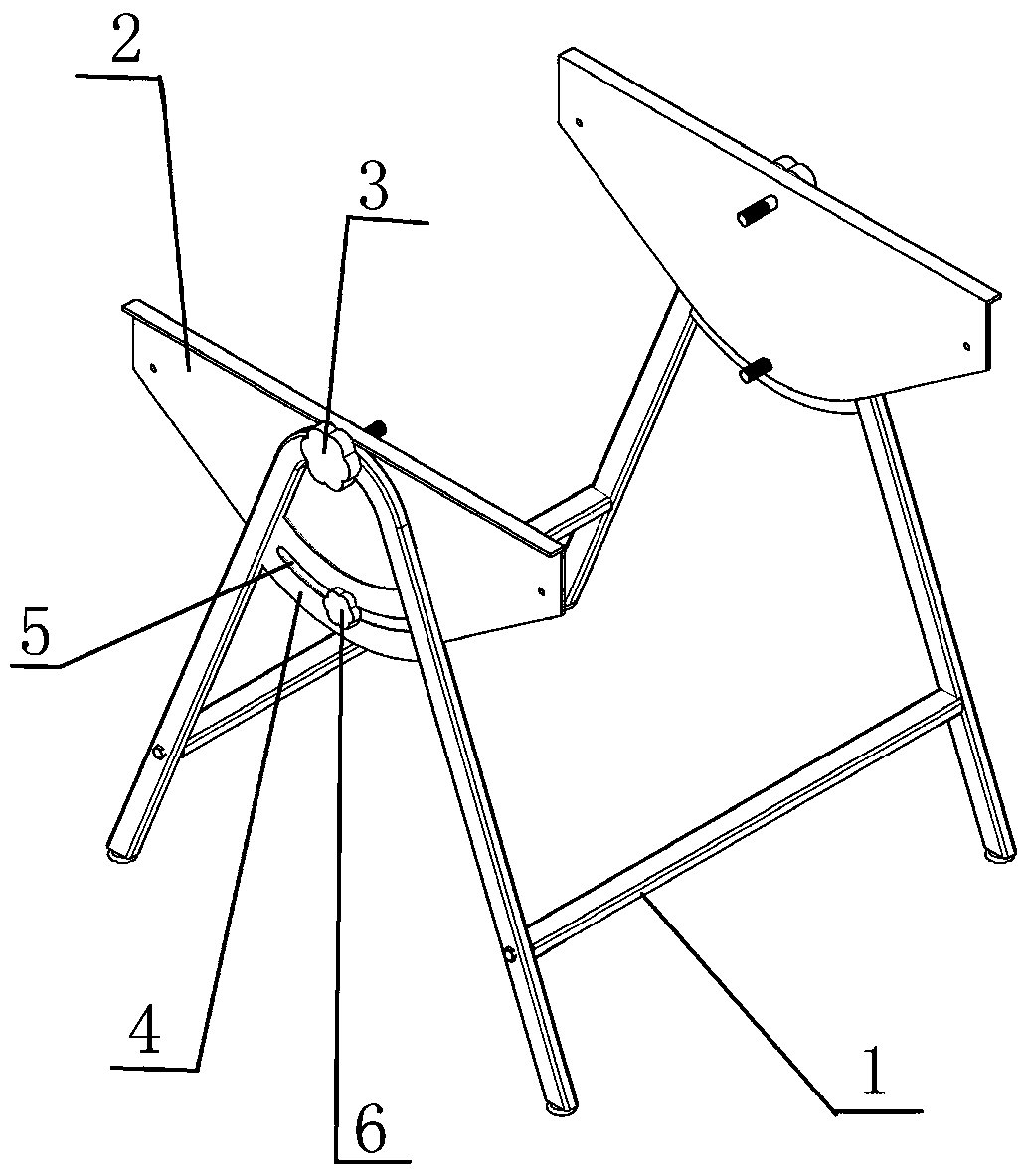

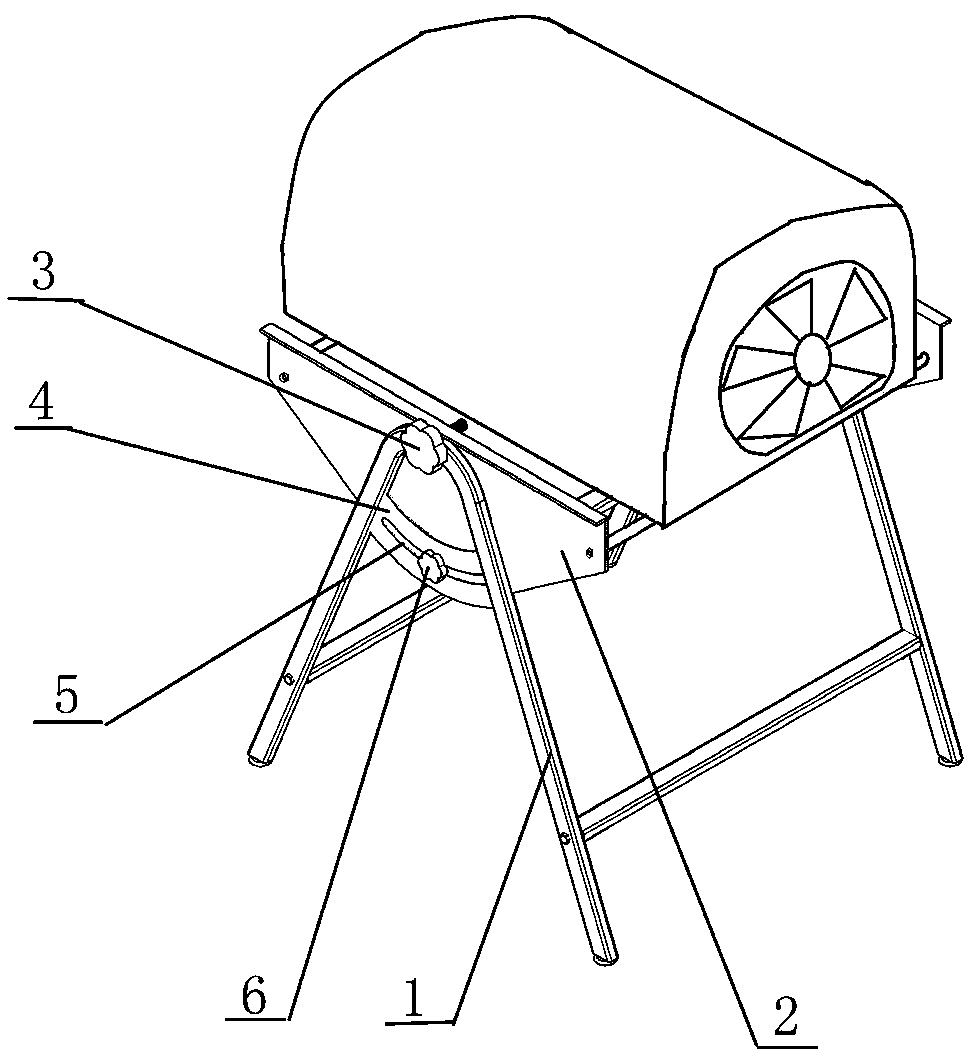

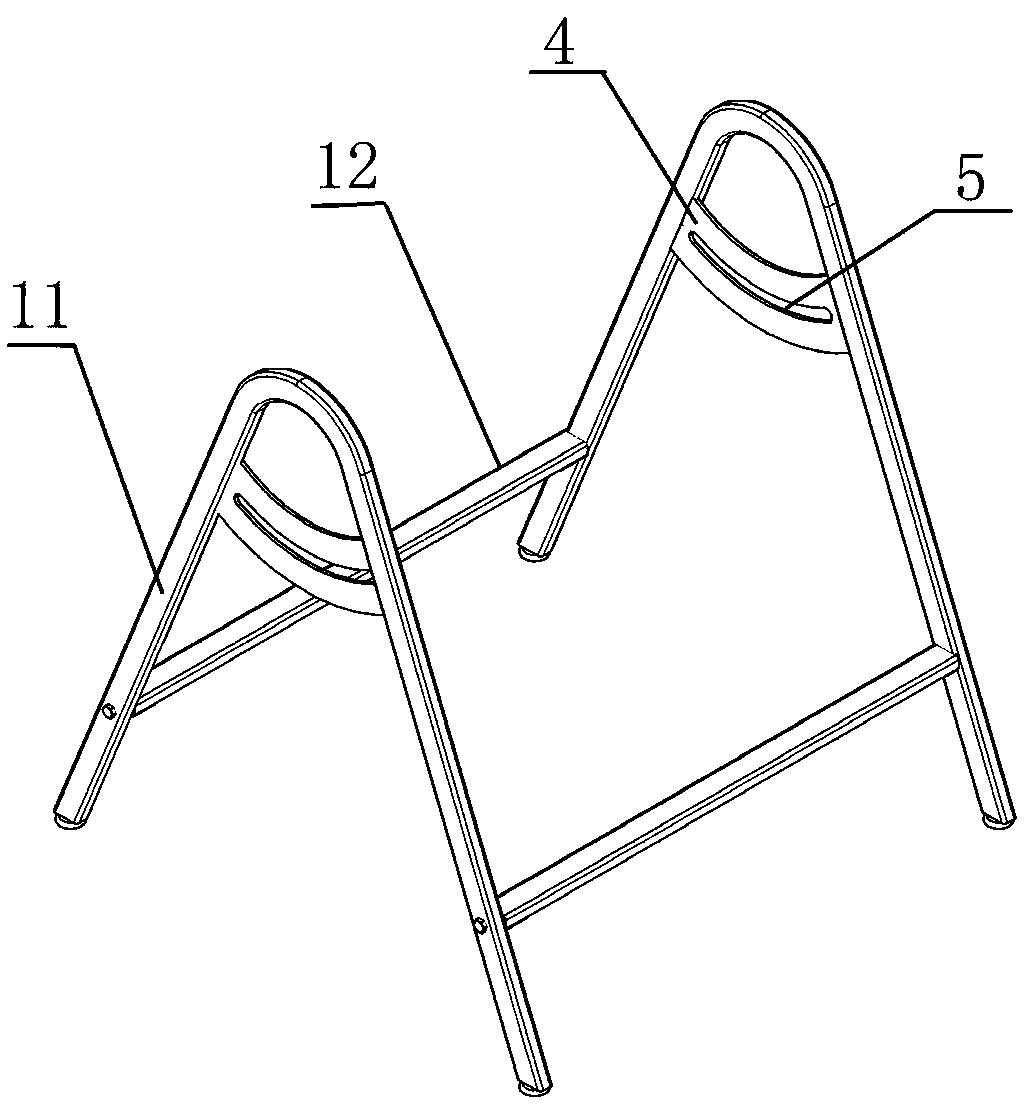

[0019] Such as figure 1 with figure 2 As shown, a vertical wind direction adjustment frame includes a bracket 1, and both sides of the bracket 1 are provided with a rotating plate 2 and a knob 3. The rotating plate 2 is fixed on the bracket 1 by the knob 3 and can rotate relative to the bracket 1 to dissipate heat. The fan is fixed between the rotating plates 2 on both sides of the bracket 1, the bracket 1 is provided with a horizontal plate 4, the horizontal plate 4 is provided with a groove 5, the rotating plate 2 is provided with locking bolts 6, and the locking bolts 6 pass through the grooves in turn 5. The rotating plate 2 and the nut are threaded.

[0020] Install the cooling fan between the two rotating plates 2 on the bracket 1, fix the cooling fan with the knob 3 and the nut, and make the cooling fan rotate relative to the bracket 1 with the knob 3 as the axis, when the cooling fan is rotated to a suitable angle , utilize the lock bolt 6 to cooperate with the nut to

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap