Fireproof rolling shutter door

A technology of rolling doors and rolling panels, which is applied in the field of rolling doors, can solve the problems of loss of fire prevention function and lack of fixing function of rolling doors, etc., and achieve the effect of enhancing fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Any feature disclosed in this specification, unless specifically stated, can be replaced by other alternative features that are equivalent or have similar purposes. That is, unless expressly stated otherwise, each feature is one example only of a series of equivalent or similar features.

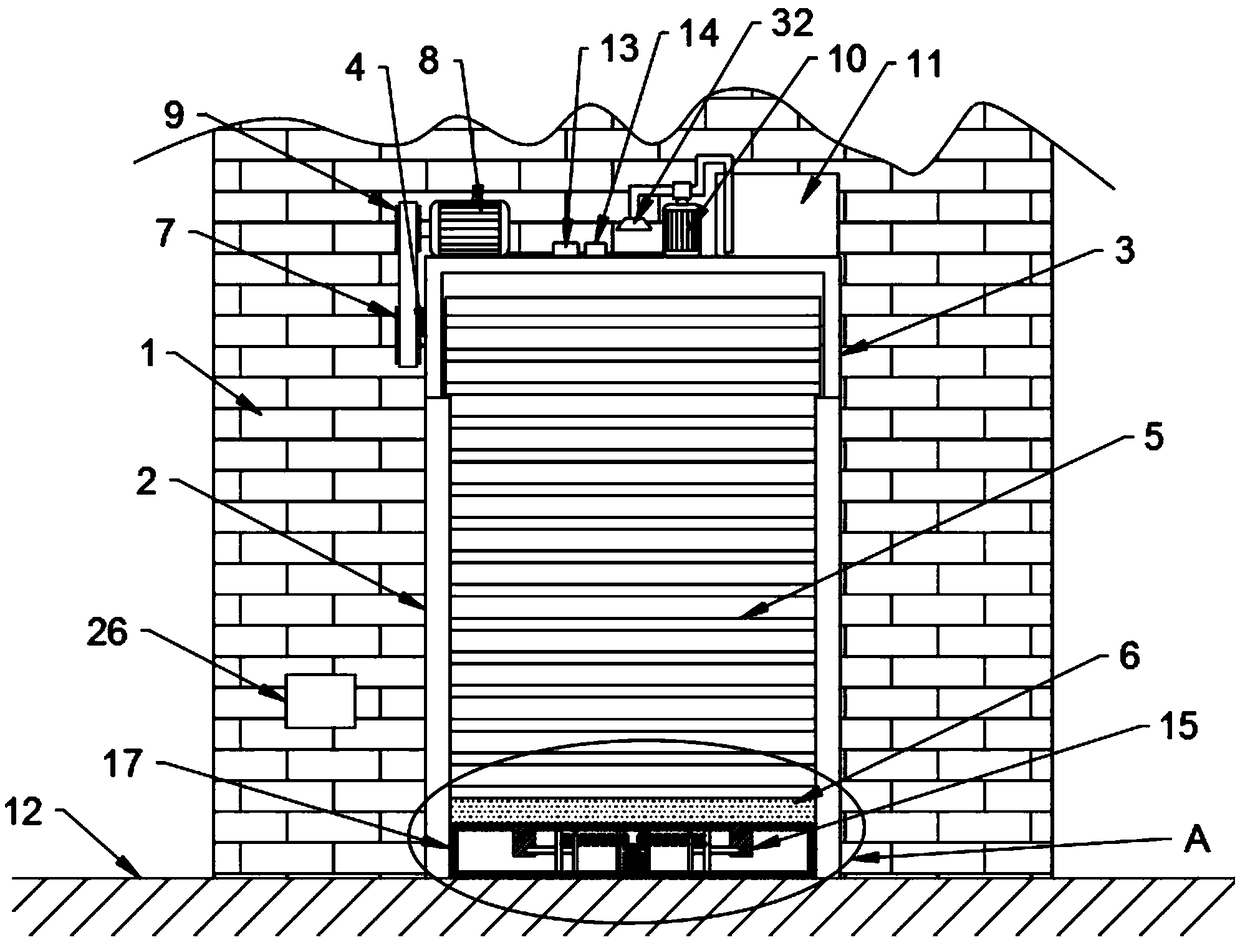

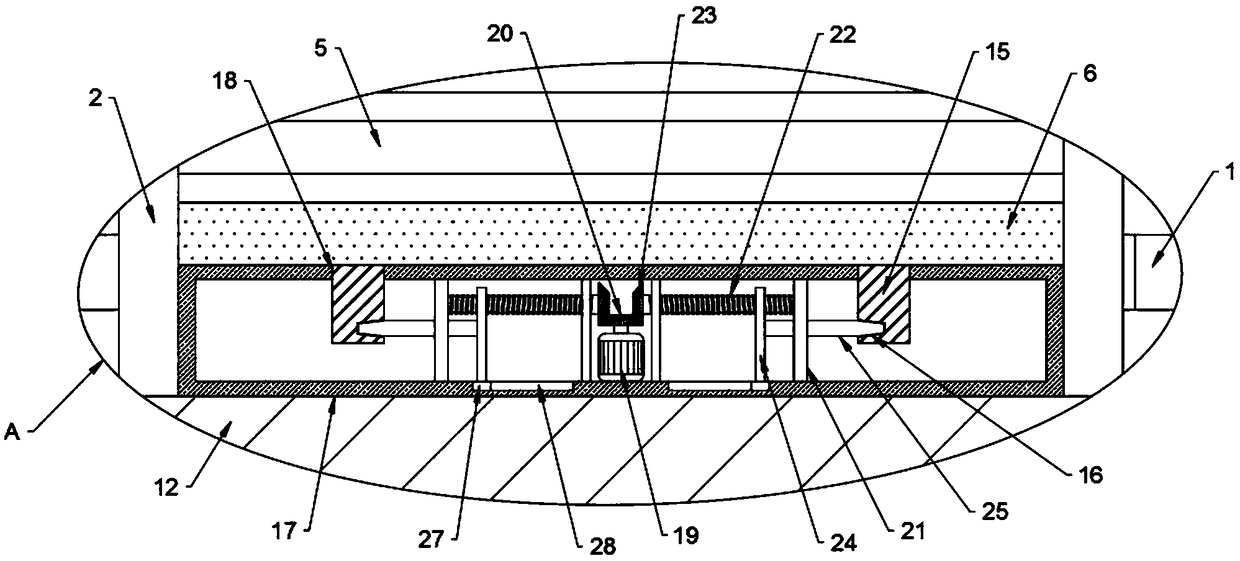

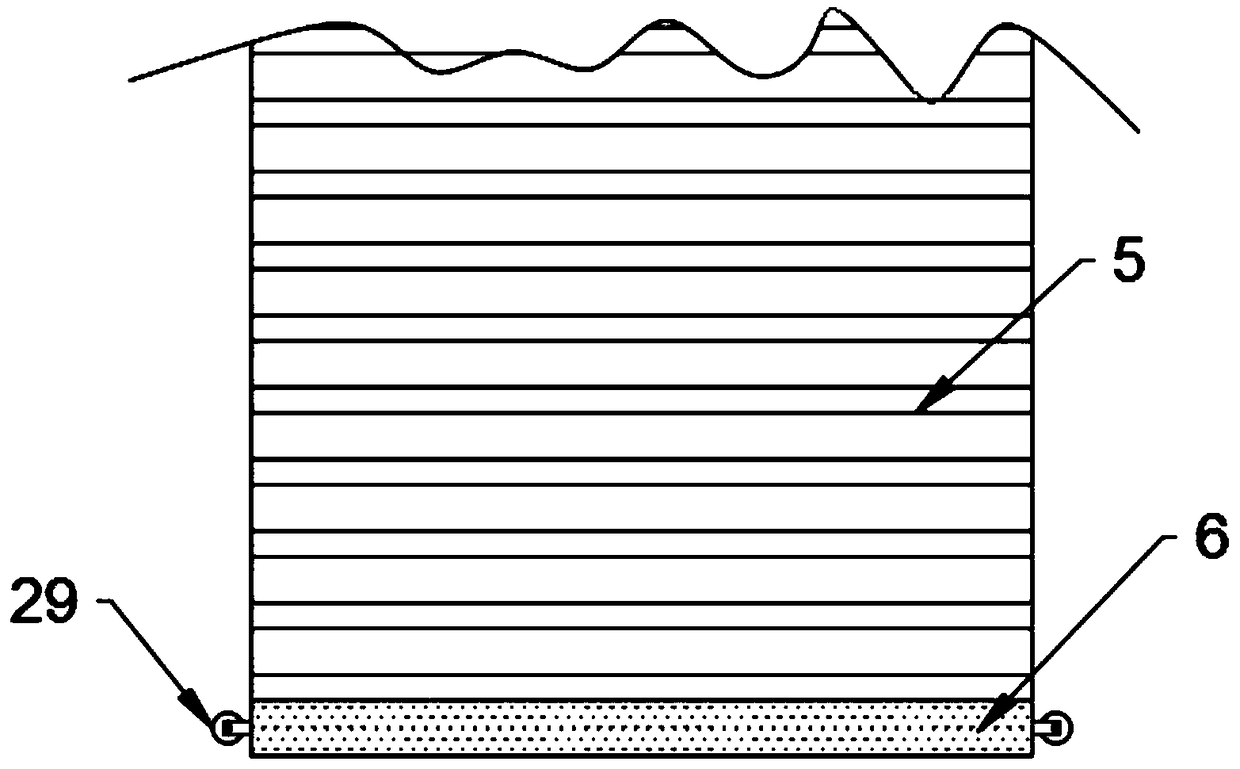

[0017] Such as Figure 1-Figure 5 A fire-proof rolling door shown includes a wall 1, a vertical plate 2, a U-shaped connecting frame 3, a rolling plate 5, a counterweight plate 6, a driving motor 8, a water pump 10, a floor 12, a storage box 17 and a control panel 26 , the top of the ground 12 is fixed with a wall 1, and the wall 1 is provided with an entrance and exit, and the side wall of the wall 1 is symmetrically fixed with a riser 2, and the two risers 2 are respectively arranged at the entrance and exit On both sides, the bottom of the riser 2 is fixedly connected to the top of the ground 12, the top of the riser 2 is fixed with a U-shaped connecting frame 3, and one side wall of

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap