Convenient-to-move textile yarn machinery equipment

A technology for mechanical equipment and textile yarns, applied in the field of textile yarn machinery and equipment, can solve the problems of inability to move, easily blocked by waste water, and inconvenient to use, and achieves the effects of simple structure, easy movement, and guaranteed use environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

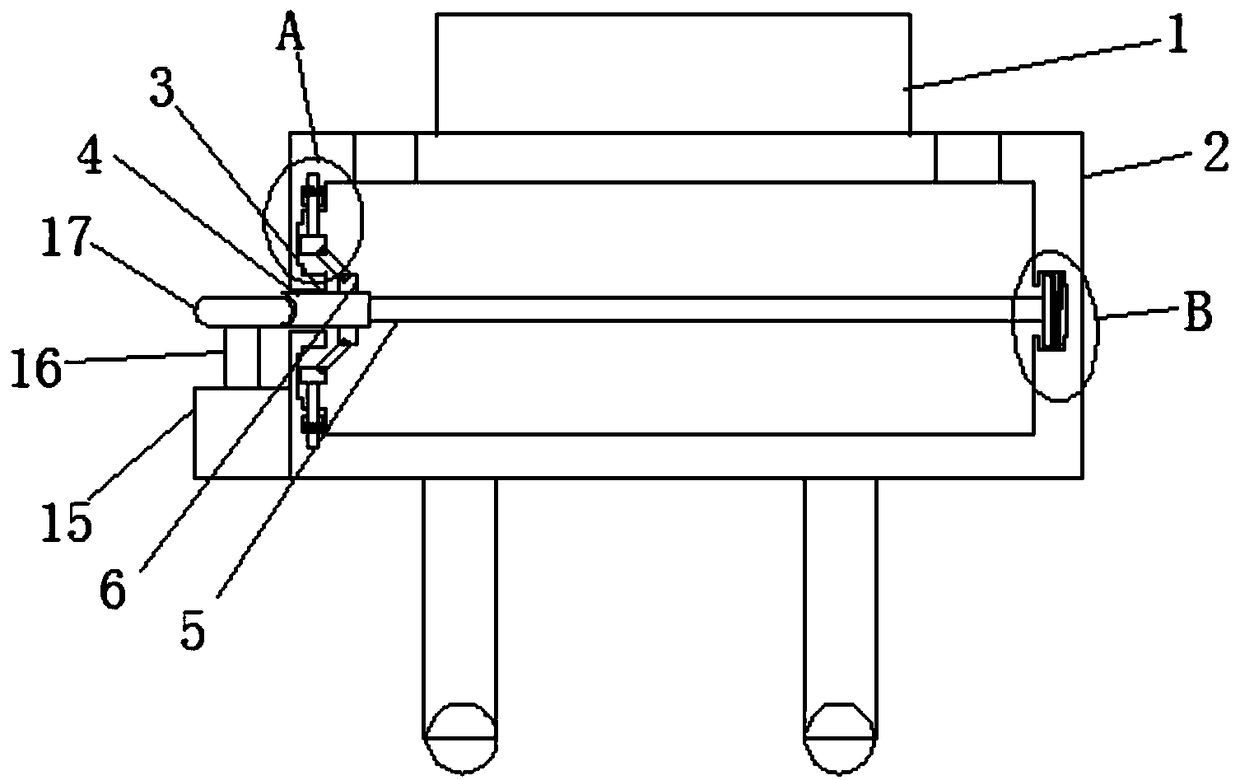

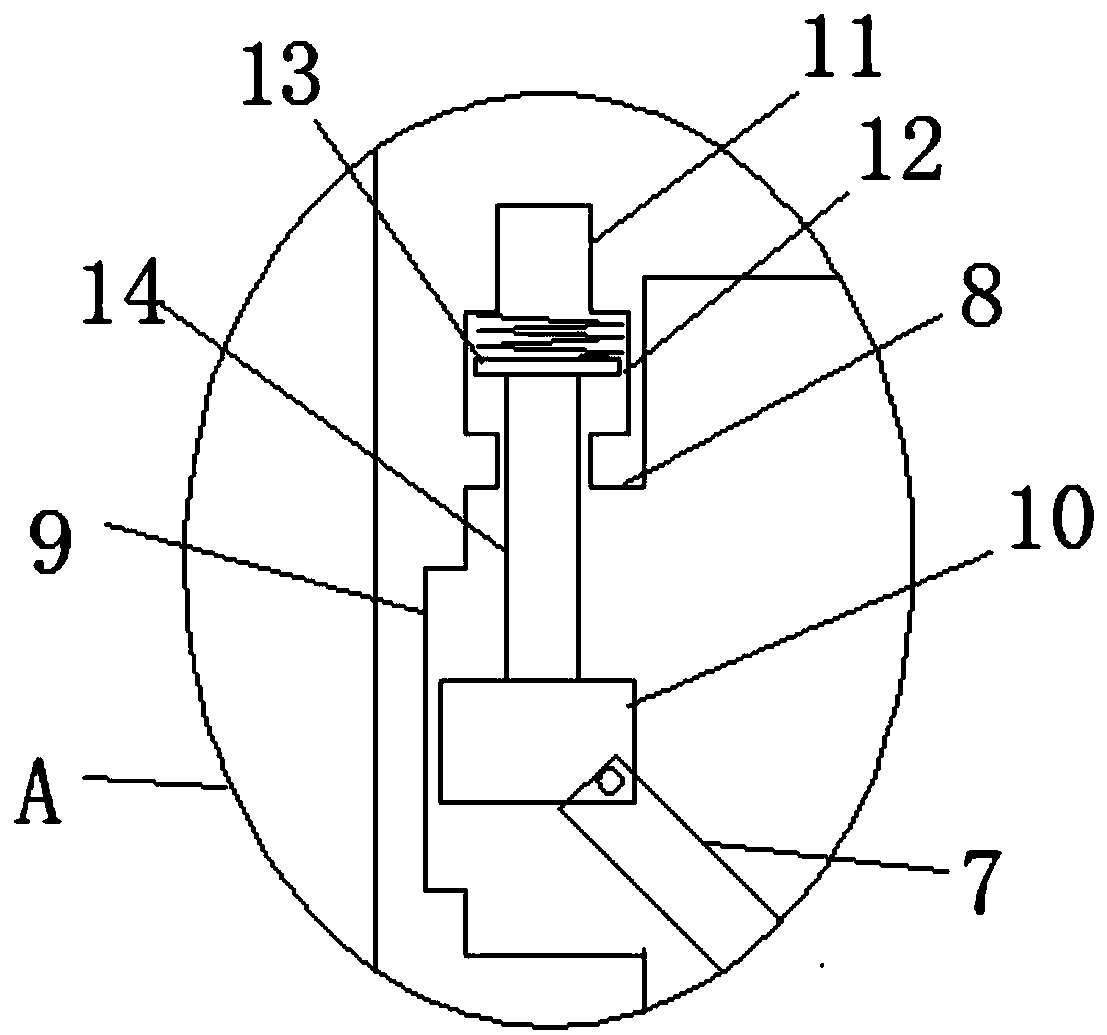

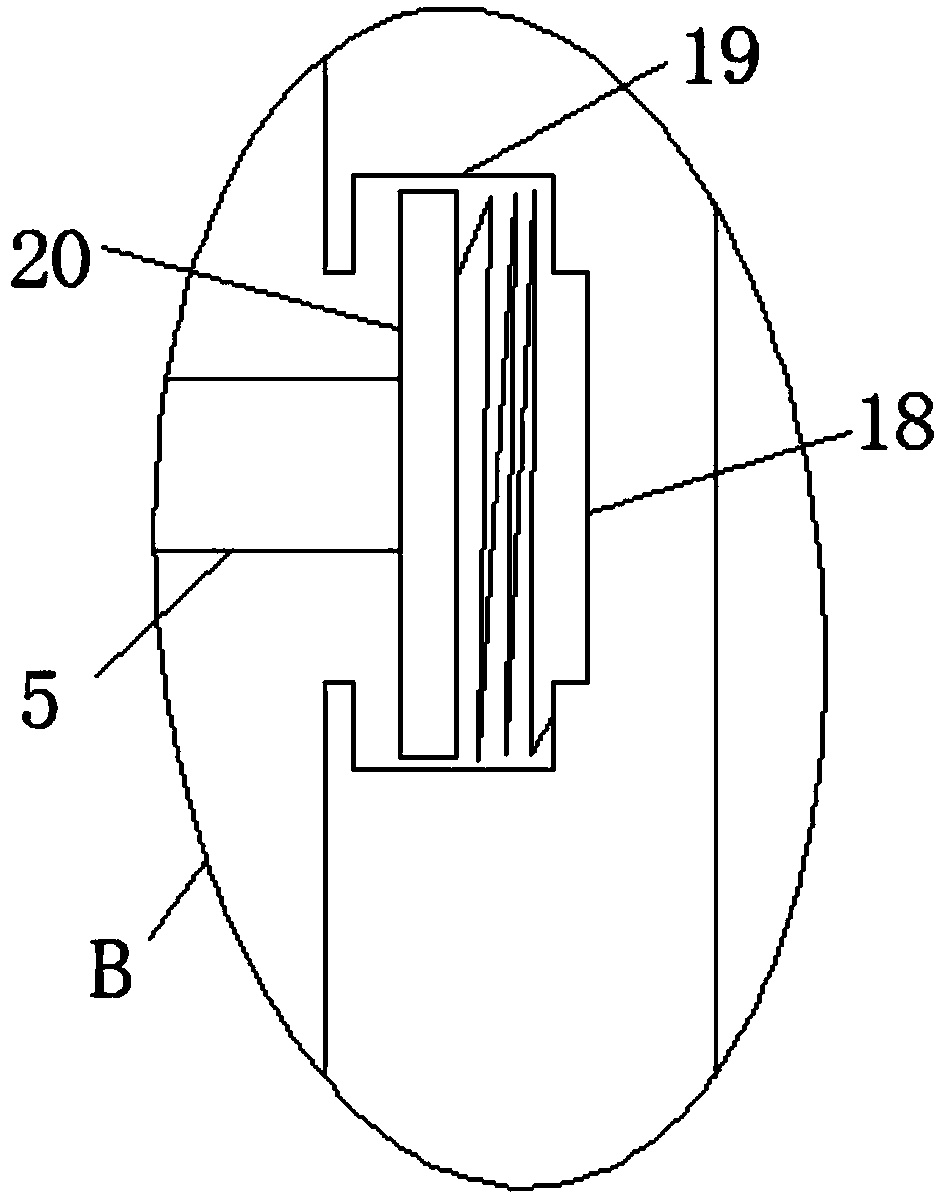

[0019] refer to Figure 1-3 , a kind of textile yarn machine equipment that is easy to move, includes a machine body 1, a waste water tank 2 is fixedly installed on the bottom side of the machine body 1, and a sliding hole 3 is opened on the inner wall of one side of the waste water tank 2 along the horizontal direction, and the sliding hole 3 A vibrating block 4 is slidingly installed inside, and both sides of the vibrating block 4 extend to the outside of the sliding hole 3, and one side of the vibrating block 4 extends into the waste water tank 2 and a vibrating plate 5 is fixedly installed. The top side and bottom of the vibrating block 4 The mounting blocks 6 locat

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap