Mechanism for fixing slip fishing cylinder

A technology for fixing slips and overshots, applied to parts of bottles/cans, rigid containers, containers, etc., can solve problems such as damage, and achieve the effect of facilitating the rotation of the supporting screw

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

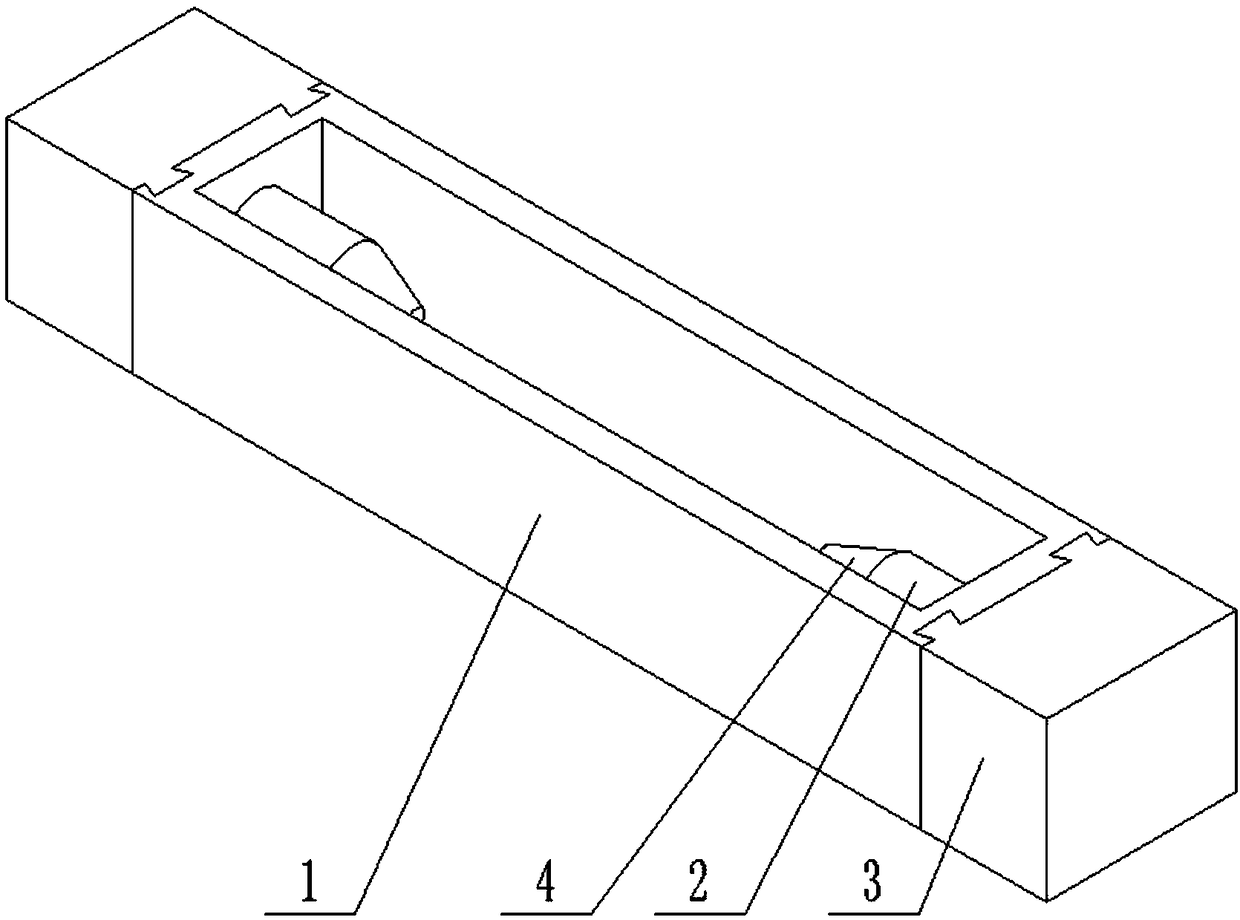

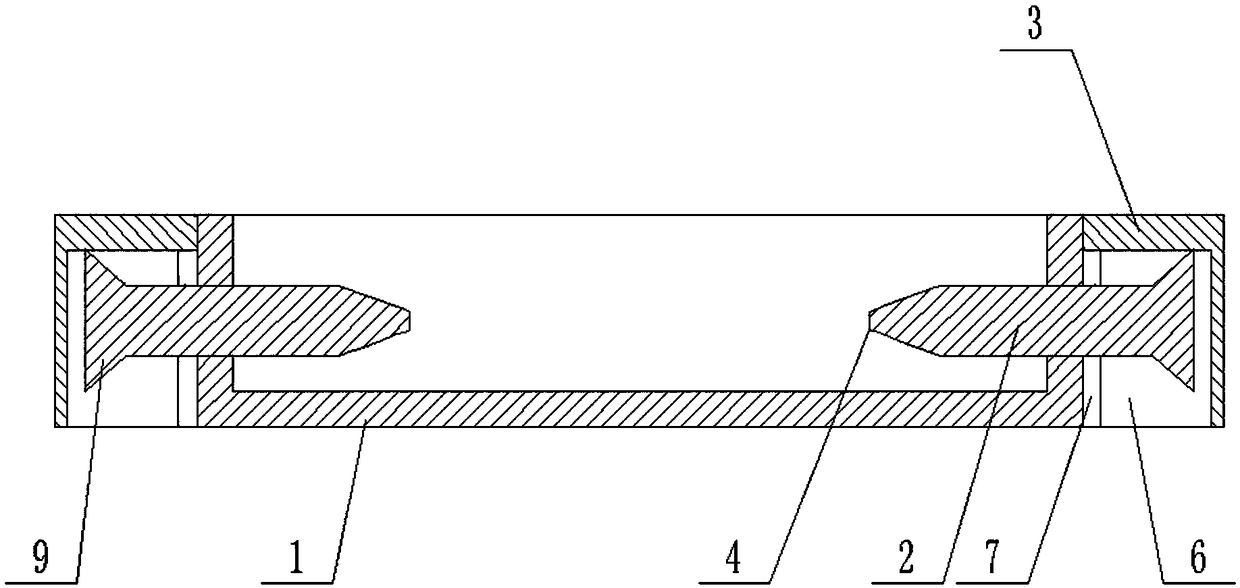

[0025] like Figure 1-Figure 4 As shown, the mechanism for fixing the slip overshot of the present invention includes a bearing box 1, a support screw 2, and a cover block 3. A pair of opposite box walls of the bearing box 1 are provided with threaded holes whose axes coincide with each other. The supporting screw rods 2 are threadedly connected with a threaded hole respectively, and the opposite surfaces of the supporting screw rods 2 are provided with a round table 4, the large end face of the round table 4 is connected with the screw rod 2, and the axis of the round table 4 is connected with the supporting screw rod 2. The axis coincides;

[0026] A chute 5 is provided on the outer surface of the threaded hole on the carrier box 1, the opening size of the chute 5 is smaller than the bottom size of the groove, and the extension axis of the chute 5 is perpendicular to the bottom of the carrier box 1, which One end close to the bottom of the box is a closed end, and the other en

Embodiment 2

[0032] This embodiment is based on Embodiment 1 to further illustrate the present invention.

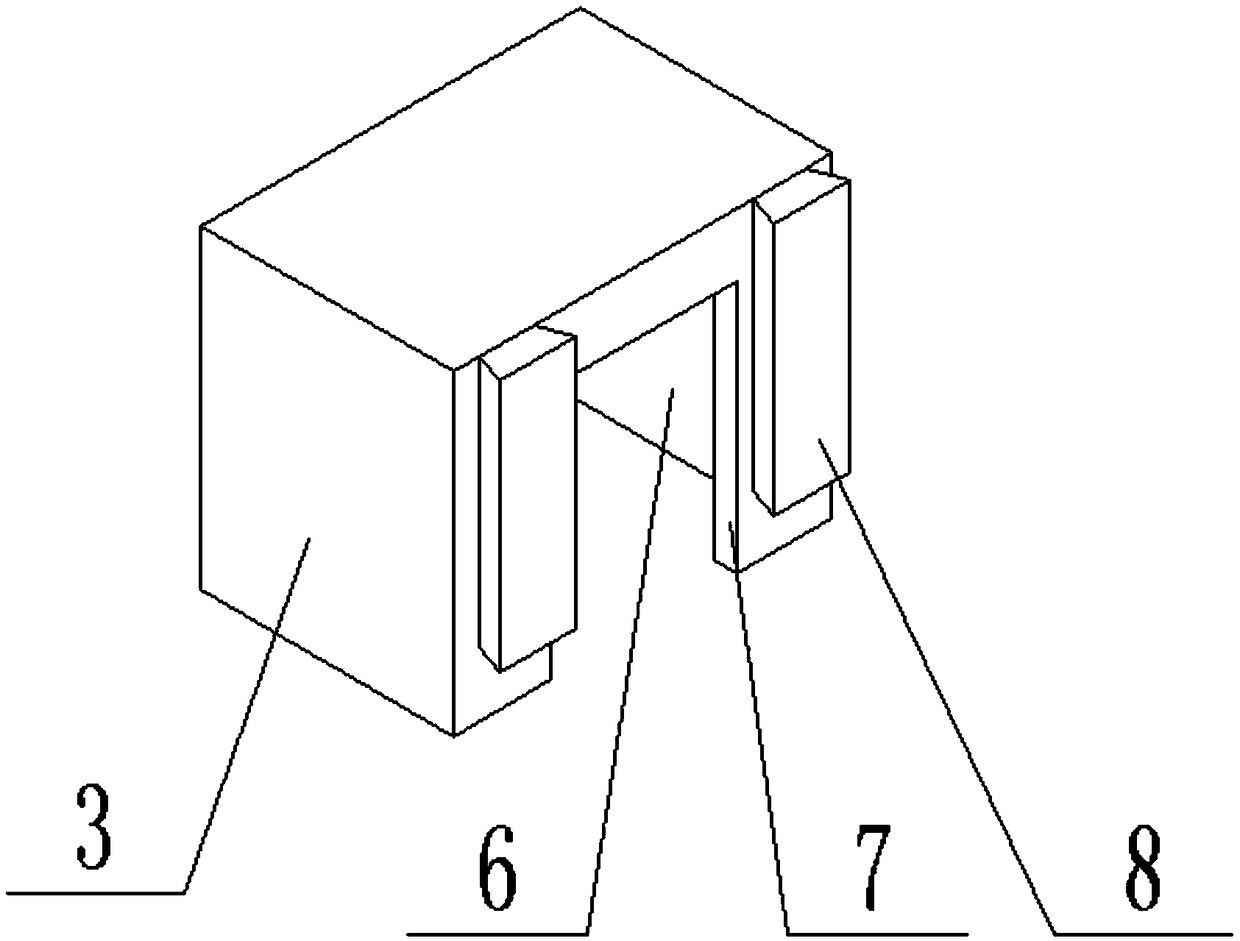

[0033] like figure 2 and Figure 4 As shown, the mechanism for fixing the slip overshot of the present invention is provided with a rotating plate 9 at the end of the supporting screw 2 away from the round platform 4 , and the rotating plate 9 is parallel to the axis of the supporting screw 2 .

[0034] The setting of the rotating plate 9 is convenient for rotating the supporting screw rod 2 to save effort.

[0035] Preferably, the rotating plate 9 is an isosceles trapezoidal plate, and the end surface where the upper bottom is located is connected with the support screw 2 .

Embodiment 3

[0037] This embodiment is based on Embodiment 1 to further illustrate the present invention.

[0038] like Figure 4 As shown, in the mechanism for fixing the slip overshot of the present invention, the chute 5 is a dovetail groove. Chute 5 can also adopt T-shaped groove.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap