Revolving drum mechanism of water-draining and slag-blocking device

A slag drum and rotary drum technology, which is applied in water conservancy projects, artificial waterways, buildings, etc., can solve the problems of difficult cleaning, easy falling of dirt, water pollution in canals, etc., and achieves a simple and convenient operation process for intercepting and cleaning dirt. Flexible, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0031] Example 1:

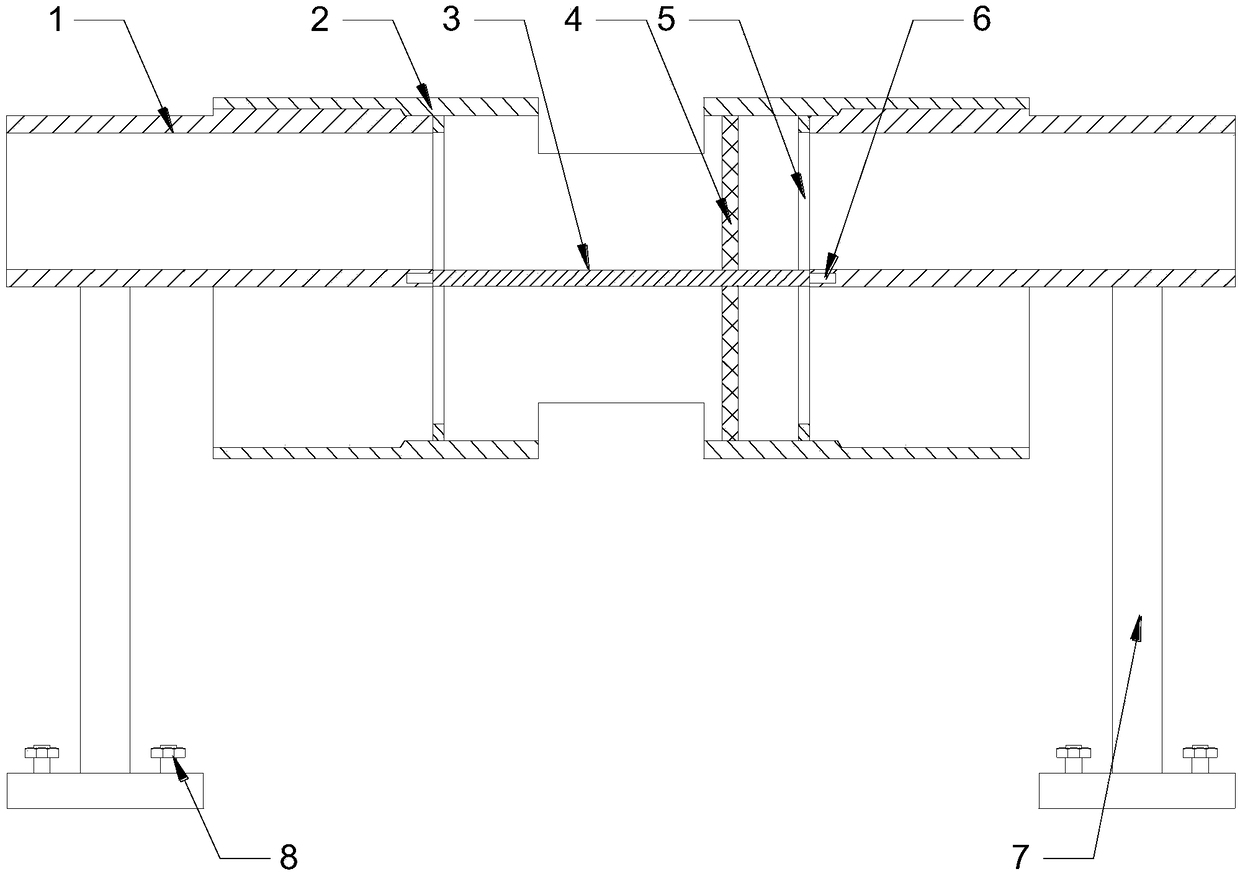

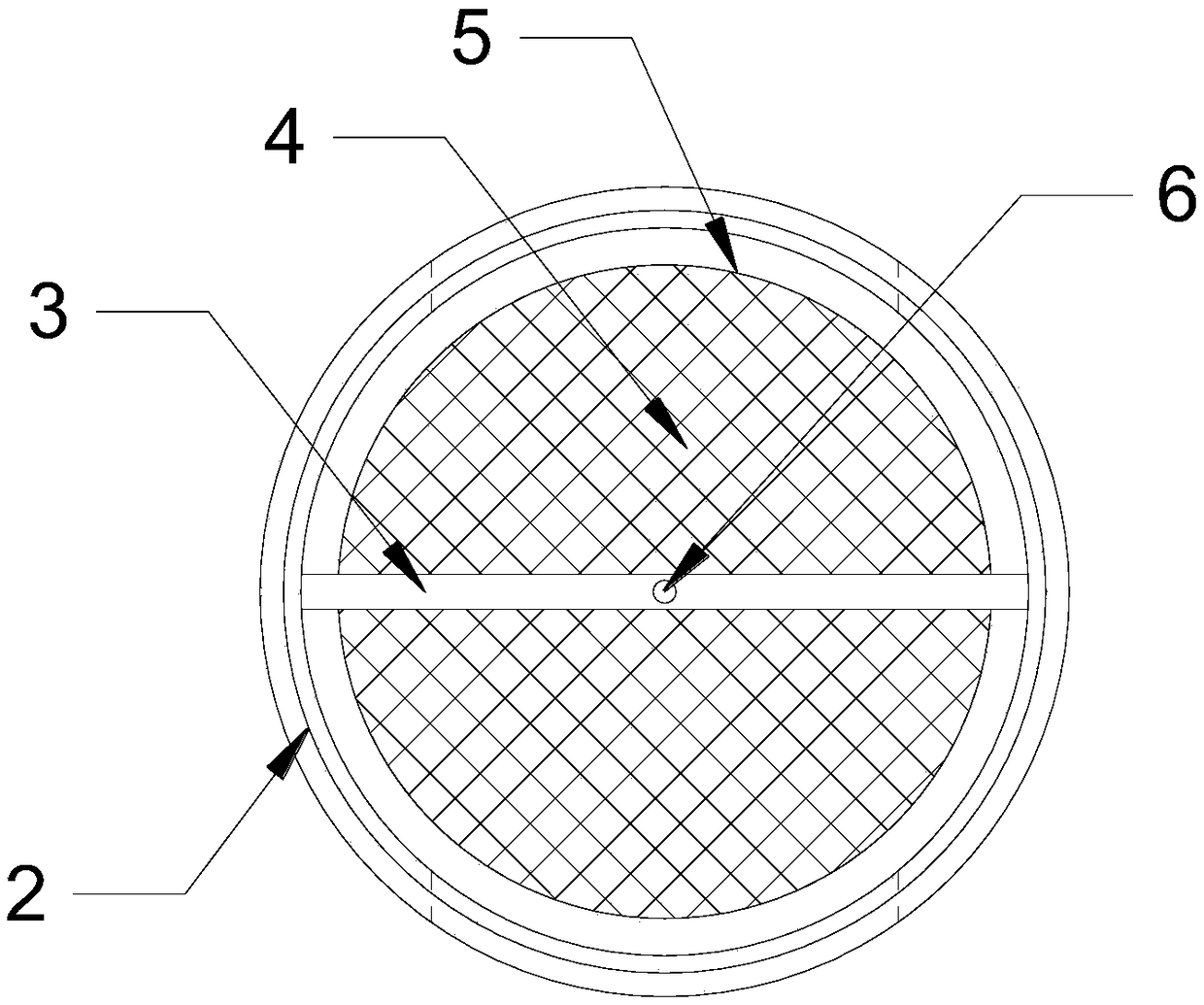

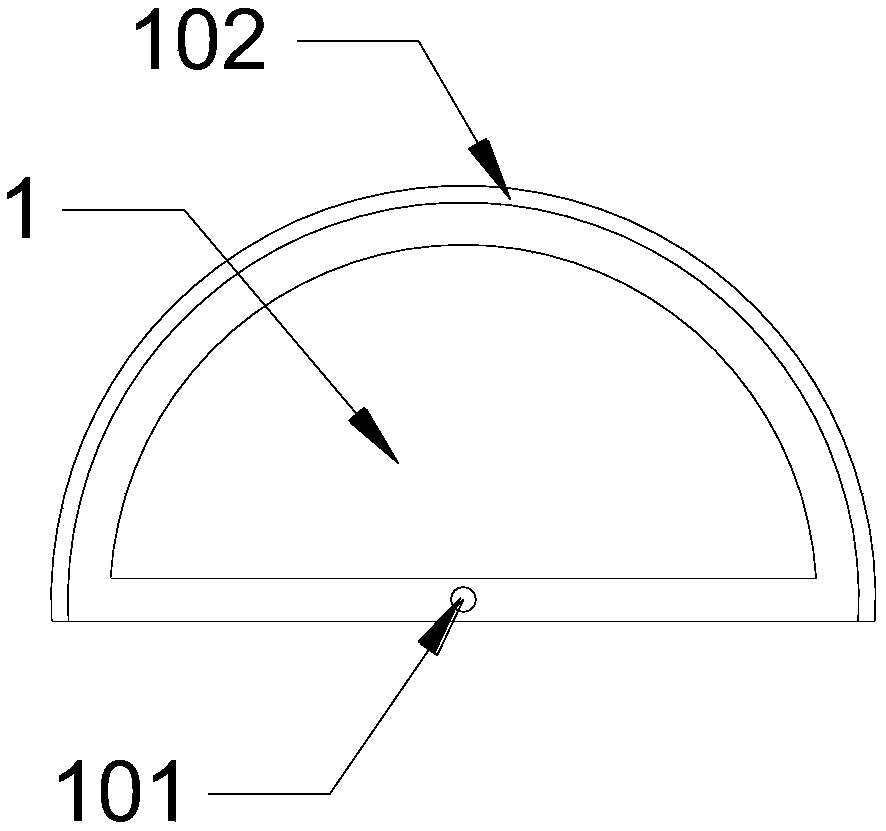

[0032] See Figure 1~6 , A rotating drum mechanism of a drainage slag blocking device, comprising two drainage channels 1, the drainage channel 1 is a sleeve with a semicircular cross section, the two drainage channels 1 are arranged opposite to each other with openings at a certain distance. 1 is equipped with a circular slag trap 2 and a partition 3 is installed in the slag trap 2. The partition 3 divides the slag trap 2 into two upper and lower semicircular aisles, and the upper and lower semicircular aisles are installed There is a slag trap 4, and the opposite slag trap 2 has a slag discharge port 201 in the cylinder body. The inner diameter of the opening at both ends of the slag trap 2 matches the outer diameter of the drainage channel 1, and the openings at both ends are respectively sleeved On the two drainage channels 1, the axis of the drainage channel 1 and the slag trap tube 2 coincide.

[0033] In the present invention, the water flow enters from th

Example Embodiment

[0034] Example 2:

[0035] See Figure 1~6 , A rotating drum mechanism of a drainage slag blocking device, comprising two drainage channels 1, the drainage channel 1 is a sleeve with a semicircular cross section, the two drainage channels 1 are arranged opposite to each other with openings at a certain distance. 1 is equipped with a circular slag trap 2 and a partition 3 is installed in the slag trap 2. The partition 3 divides the slag trap 2 into two upper and lower semicircular aisles, and the upper and lower semicircular aisles are installed There is a slag trap 4, and the opposite slag trap 2 has a slag discharge port 201 in the cylinder body. The inner diameter of the opening at both ends of the slag trap 2 matches the outer diameter of the drainage channel 1, and the openings at both ends are respectively sleeved On the two drainage channels 1, the axis of the drainage channel 1 and the slag trap tube 2 coincide.

[0036] A rotating shaft 6 is provided on both sides of the par

Example Embodiment

[0039] Example 3:

[0040] See Figure 1~6 , A rotating drum mechanism of a drainage slag blocking device, comprising two drainage channels 1, the drainage channel 1 is a sleeve with a semicircular cross section, the two drainage channels 1 are arranged opposite to each other with openings at a certain distance. 1 is equipped with a circular slag trap 2 and a partition 3 is installed in the slag trap 2. The partition 3 divides the slag trap 2 into two upper and lower semicircular aisles, and the upper and lower semicircular aisles are installed There is a slag trap 4, and the opposite slag trap 2 has a slag discharge port 201 in the cylinder body. The inner diameter of the opening at both ends of the slag trap 2 matches the outer diameter of the drainage channel 1, and the openings at both ends are respectively sleeved On the two drainage channels 1, the axis of the drainage channel 1 and the slag trap tube 2 coincide.

[0041] The slag discharge openings 201 corresponding to the up

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap