Anti-backfilling method and system of sewage pipe and/or primary rain pipe of diversion well

A diversion well and sewage pipe technology, applied in the waterway system, sewage discharge, water supply equipment, etc., can solve the problems of electric shock hazard, difficult power supply, easy leakage and other problems, and achieve no occupation of height space, mature and reliable price, anti-clogging powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

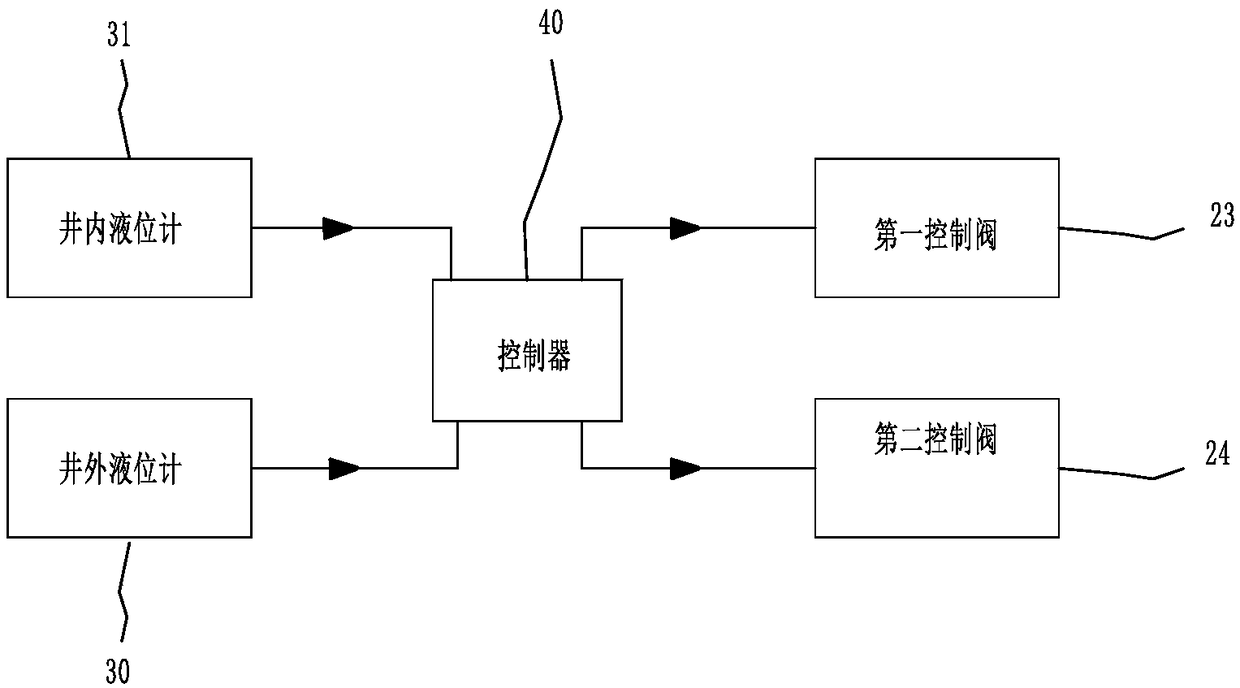

[0072] see image 3 , an embodiment of the present invention provides a method for preventing backflow of sewage pipes and / or primary rain pipes of diversion wells:

[0073] Real-time collection of the liquid level information H1 in the diversion well and the liquid level information H2 in the inspection well where the outlet pipe of the diversion well is connected to the sewage pipe and / or the initial rain pipe,

[0074] When H2≥H1, implement the anti-backflow procedure: inflate the pneumatic shut-off device, and close the outlet pipe to prevent the fluid in the sewage pipe or the primary rain pipe from being poured into the diversion well;

[0075] When the liquid level information H2

[0076] The controller is also equipped with an anti-backflow water level H corresponding to the bottom elevation of the outlet pipe.

[0077] When H2≥H and H2≥H1, execute the anti-backflow program;

[0078] When H2

Embodiment 2

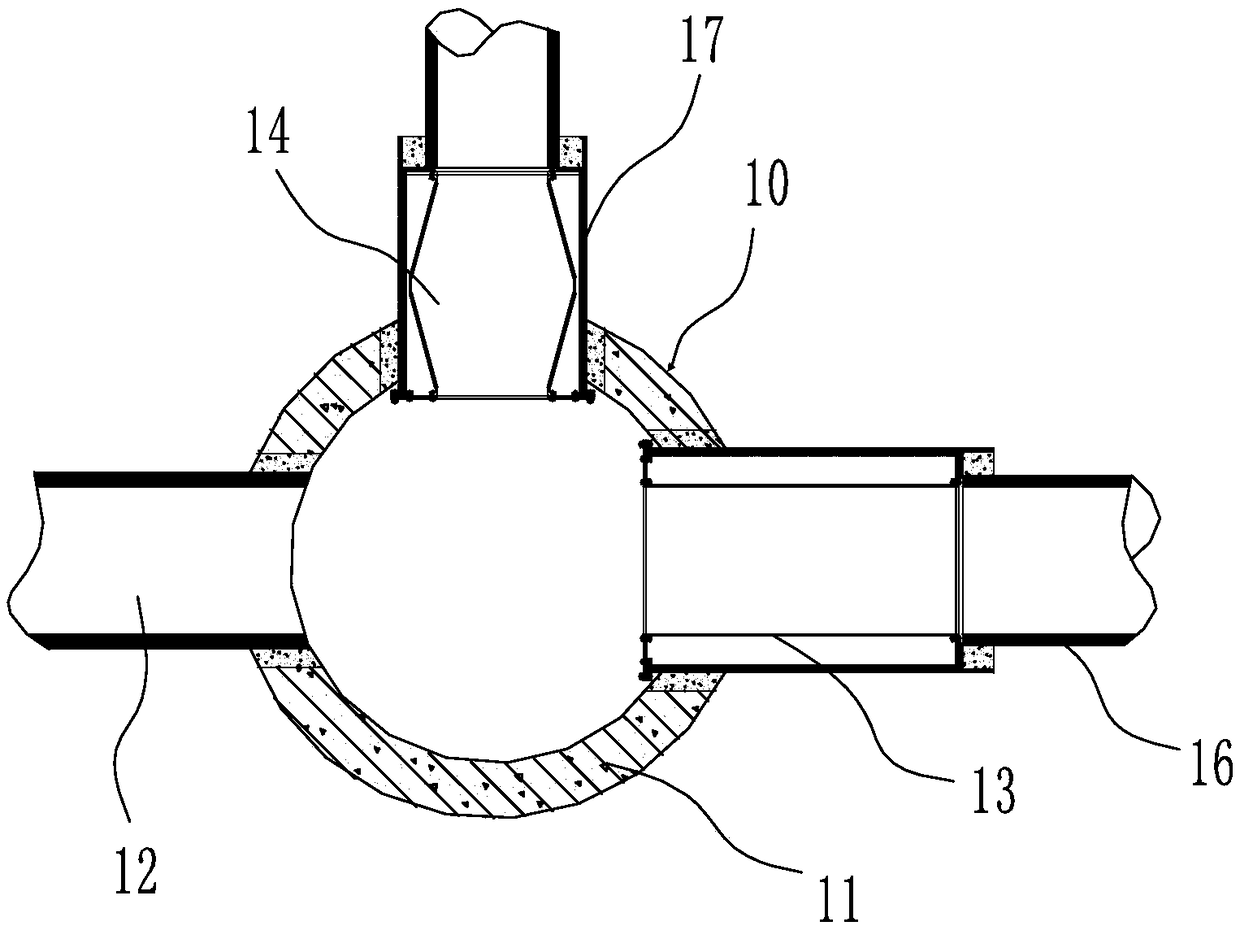

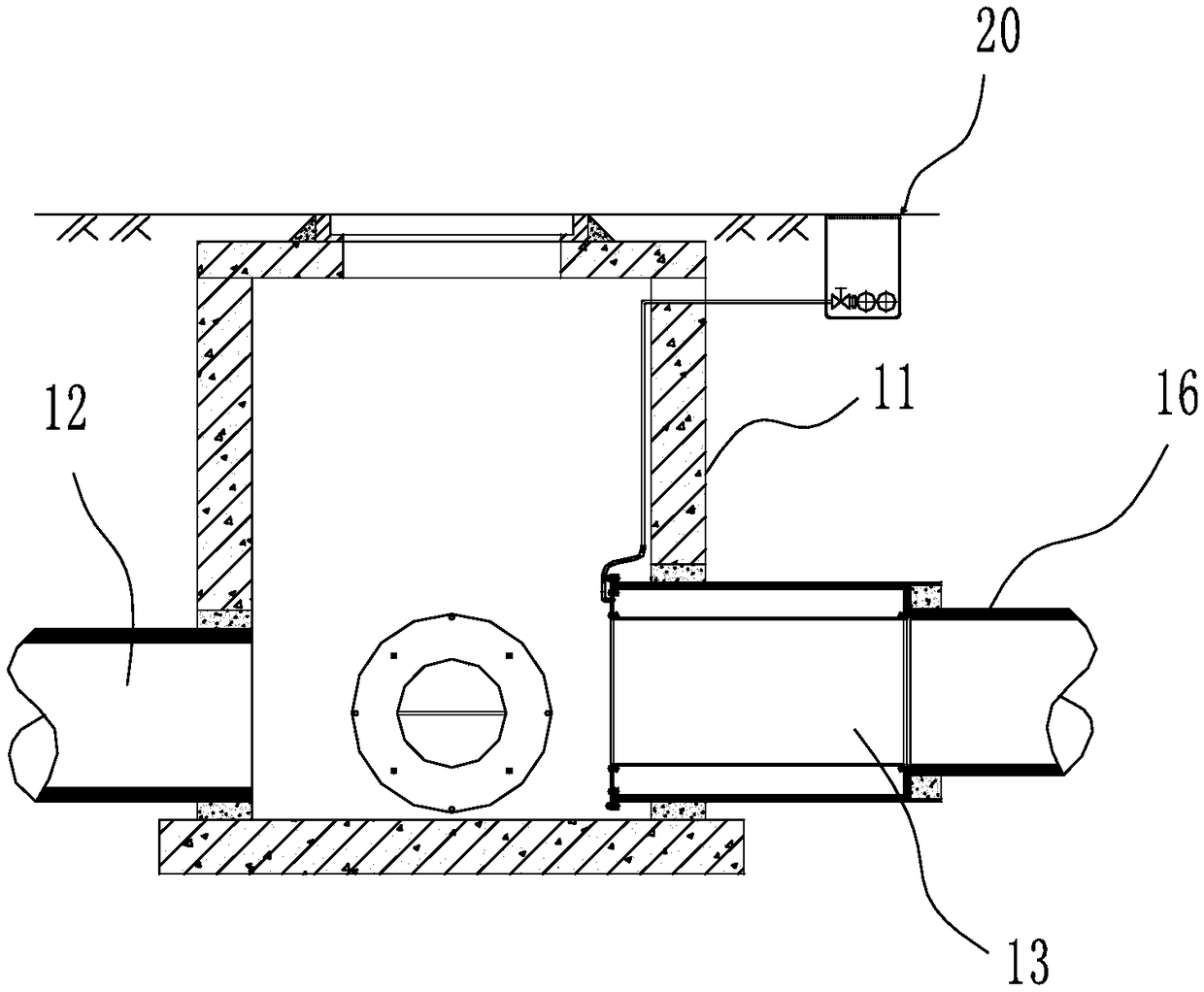

[0085] see figure 1 , figure 2 , image 3 , Figure 7 As shown, the embodiment of the present invention provides an anti-backflow system for sewage pipes and / or primary rain pipes of diversion wells, including: compressed gas source, gas delivery pipe, control valve 20, liquid level gauge 30 outside the well, liquid level in the well Potometer 31 and pneumatic shunt well 10.

[0086] The pneumatic diversion well 10 comprises a diversion well body 11 and a pneumatic shut-off device and a well liquid level gauge 31 arranged in the diversion well body 11, an outside liquid level gauge 30 arranged in an inspection well 19 outside the diversion well body 11,

[0087] The form of the diversion well 10 in this embodiment is form one: the diversion well body is provided with a water inlet 12 and two water outlets, which are respectively the first water outlet and the second water outlet, and the first water outlet passes through the first water outlet. The water pipe 16 is connect

Embodiment 3

[0095] On the basis of embodiments 1 and 2, the system also includes other measuring instruments for detecting measurement information in or outside the diversion well 10, and the measuring instruments include rain gauges, flow meters, water meters, timers, and water quality monitors. Correspondingly, the measurement information includes one or more of rainfall, instantaneous flow, cumulative flow, rainfall time, and water quality.

[0096] Wherein, the rain gauge is arranged outside the diversion well 10, and what monitors is the rainfall rainfall, and the rainfall rainfall monitored during sunny days is 0;

[0097] The flow meter is arranged on the first outlet and the second outlet of the diversion well 10, and is used for monitoring the instantaneous flow value passing through the first outlet and the second outlet, and calculates the instantaneous flow entering the diversion well 10 according to the instantaneous flow value;

[0098] The water meter is arranged on the water

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap