Roller shutter type storage box for vehicle

A rolling shutter and storage box technology, applied in the passenger space and other directions, can solve the problems of soft glue welding, easy to be scratched, and poor texture at the end of the lack of glue, and achieve the effect of better operating feel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

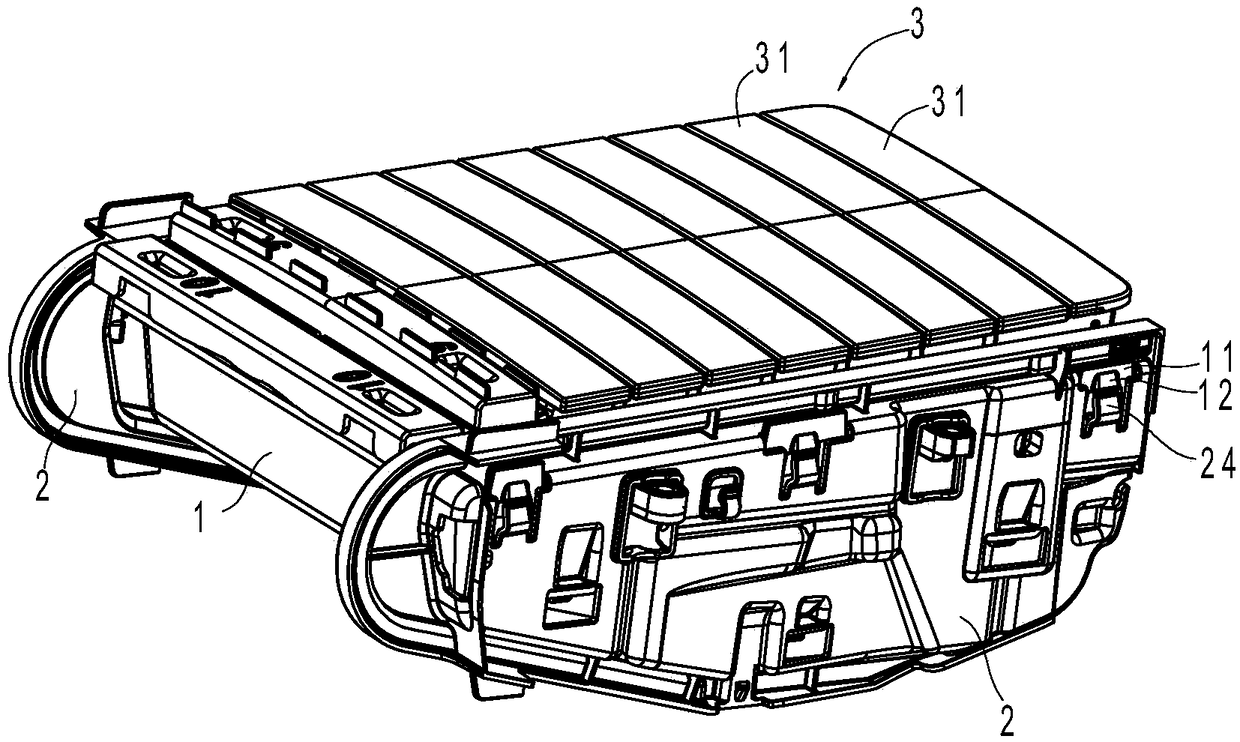

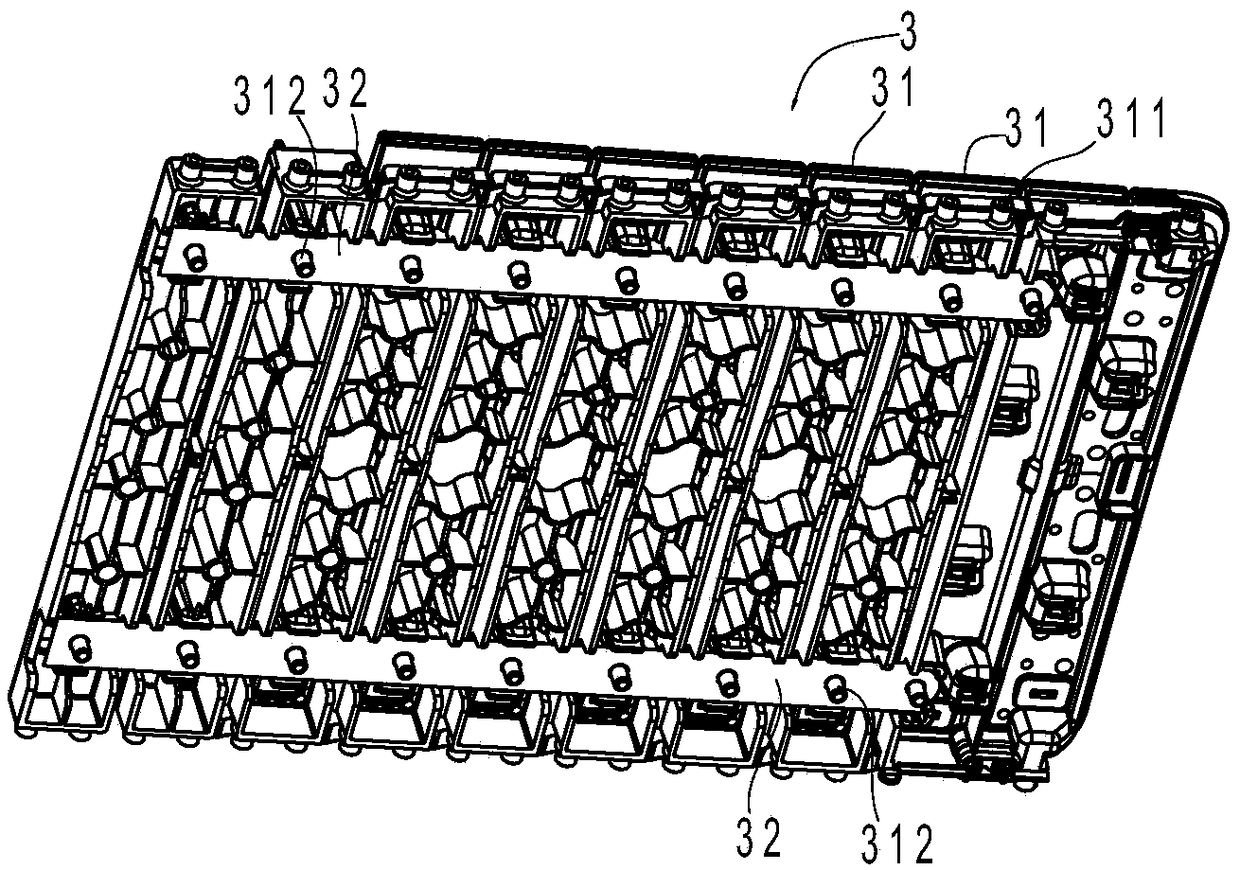

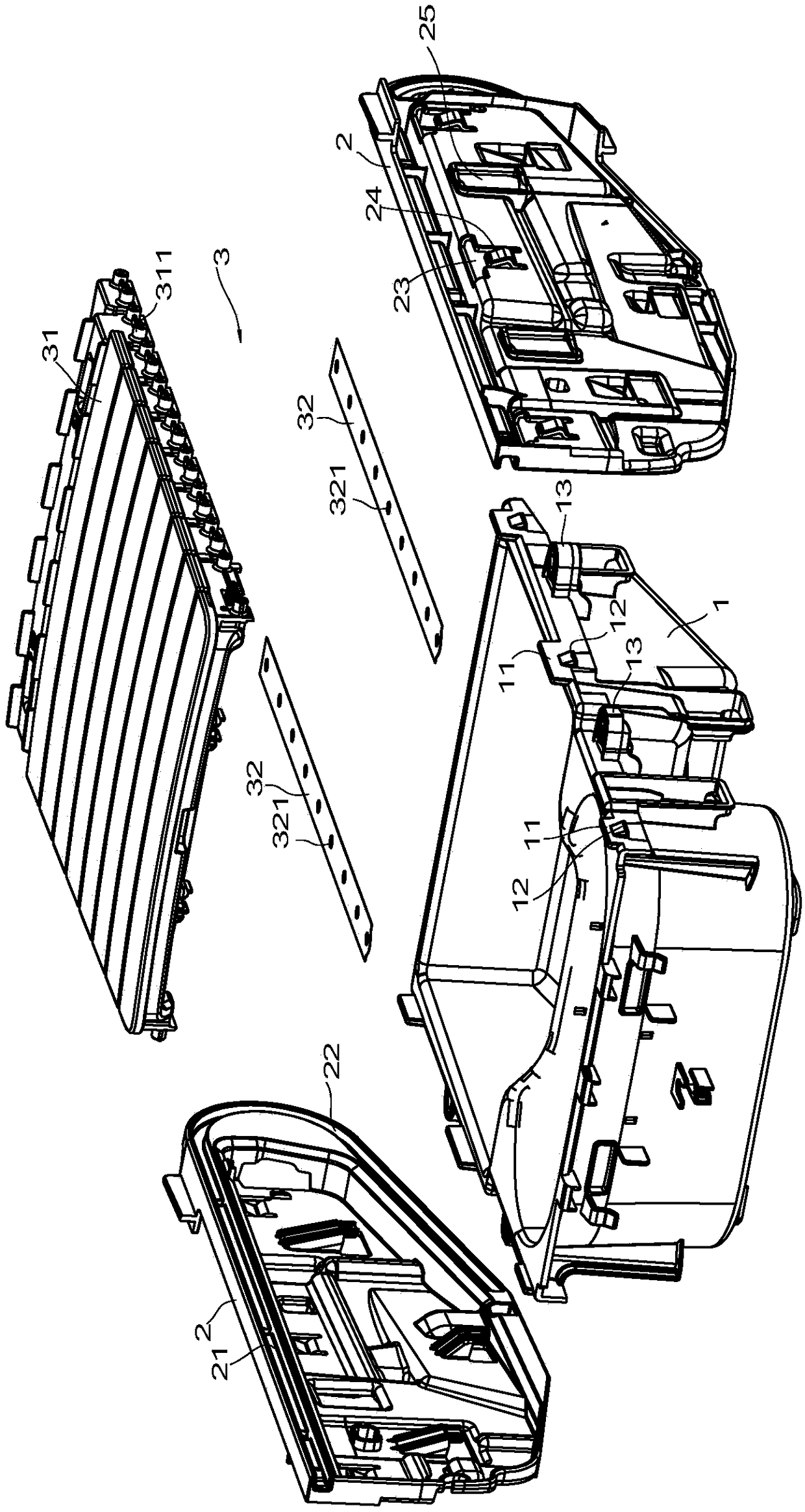

[0017] like figure 1 and image 3 As shown, the rolling shutter storage box for vehicles summarized in this embodiment includes a box body 1, a guide rail 2 and a rolling shutter cover 3, the upper end of the box body 1 is open and guide rails 2 are provided on both sides, and the rolling shutter cover 3 is arranged on the box body 1 and can slide back and forth relative to the guide rail 2; the roller shutter cover 3 includes a curtain bar 31 and a coil spring 32, and the curtain bar 31 is multiple and arranged side by side; The plurality of curtain strips 31 are assembled on the inner wall of the curtain strip 31 , specifically by welding, such as hot plate welding, vibration friction welding and the like. Two coil springs 32 are respectively arranged near the two ends of the curtain strip 31 .

[0018] combine figure 2 As shown, the inner

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap