Tubing anchor

A kind of oil pipe anchor and sliding pipe technology, which is applied in wellbore/well parts, earthwork drilling and other directions, can solve the problem of excessive wear of sucker rod and oil pipe, large mechanical loss of oil production lifting device, and high tensile strength requirements of oil pipe, etc. problem to avoid bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

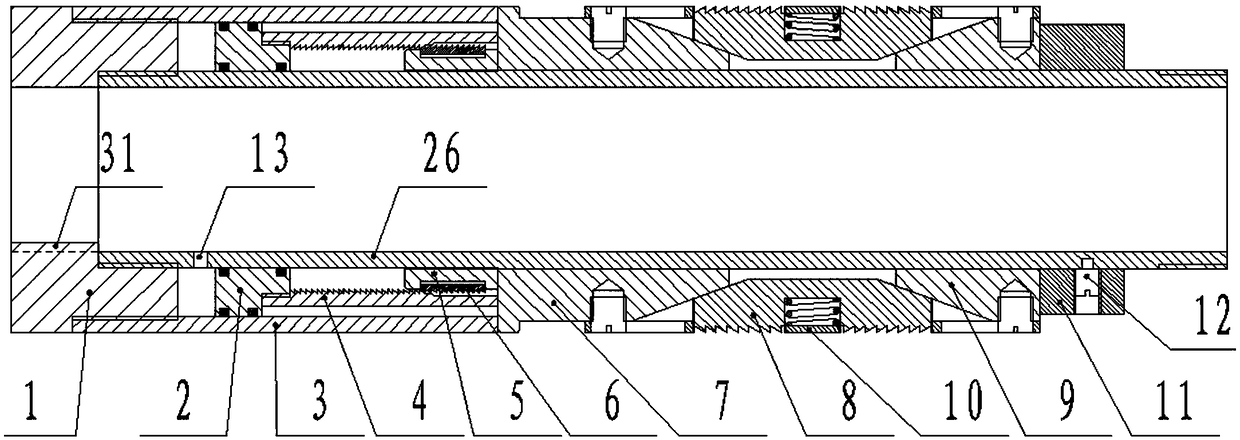

[0023] The present invention will be further described below in conjunction with accompanying drawing:

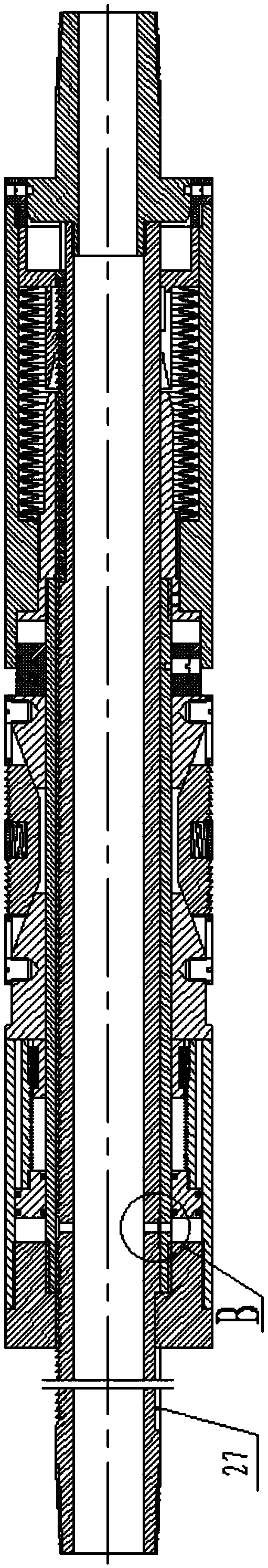

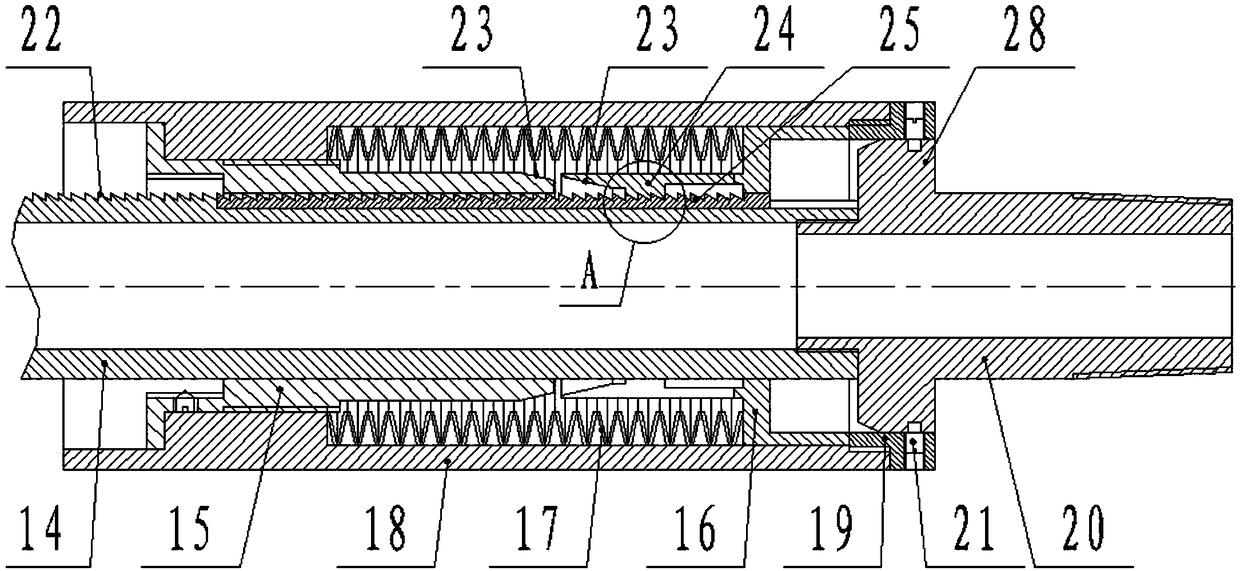

[0024] The invention includes a tubing anchor main body and a pressure-limiting tripping mechanism. The tubing anchor main body is used to realize the basic function of the tubing anchor. The pressure-limiting tripping mechanism enables relative movement between the tubing string and the tubing anchor body, thereby preventing the tubing from creeping. Purpose.

[0025] Tubing anchor main body, its structure includes upper joint 1, central tube 26, piston sleeve 3, setting piston 2, setting sleeve 4, circlip hanger 5, circlip 6, upper cone 7, slips 8, lower cone 9 , the slip installation sleeve 10 and the unsealing ring 11, the upper joint 1 is connected to the upper end of the center pipe 26 by threads, the upper end of the piston sleeve 3 is connected to the outer side of the lower end of the upper joint 1 by threads, the setting piston 2, the setting sleeve 4, the locking B

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap