Pneumatic small U-shaped pipe bender

A pipe bender and pneumatic technology, applied in the field of pneumatic small U pipe benders, can solve the problems of large force, large space and large loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

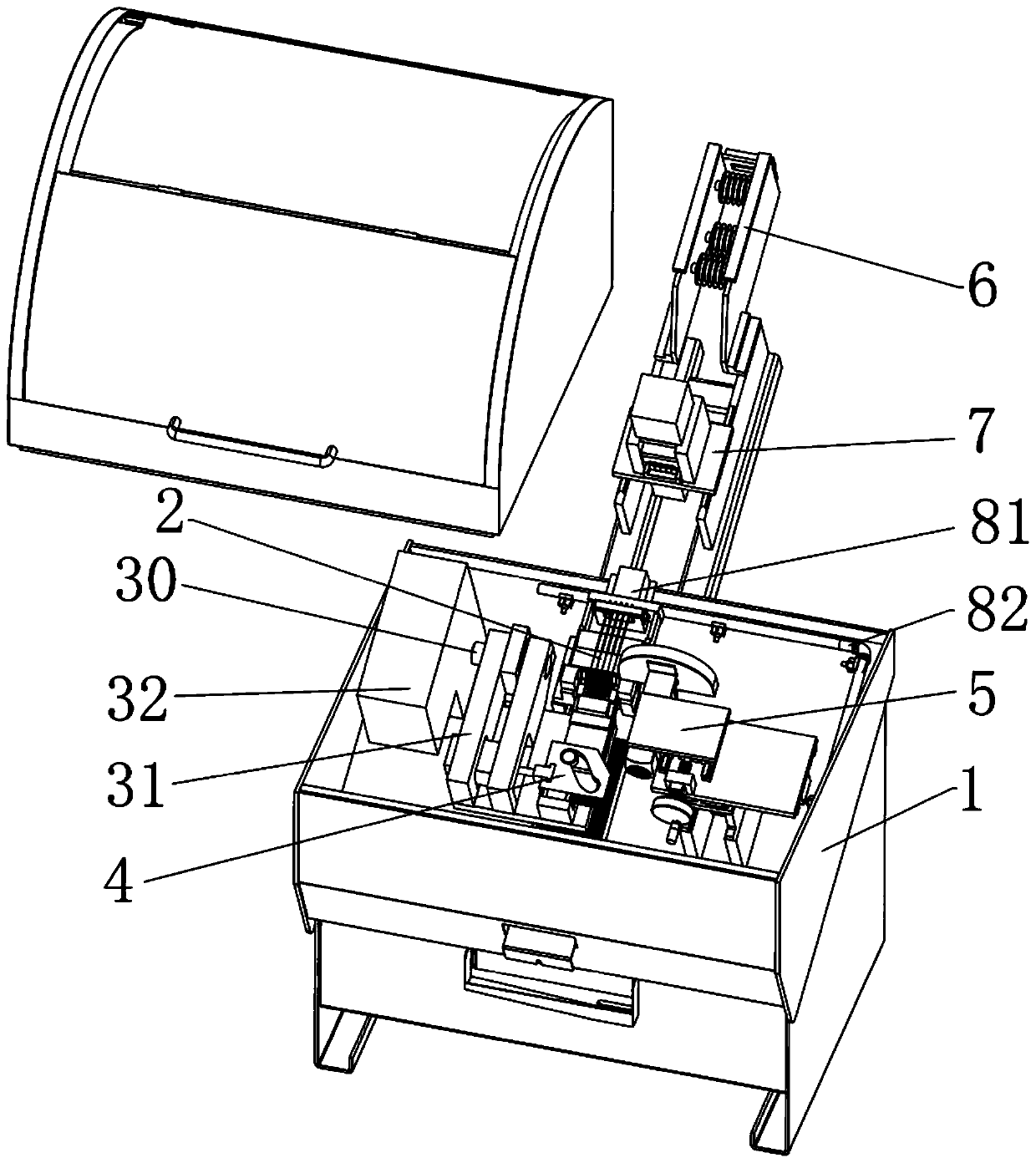

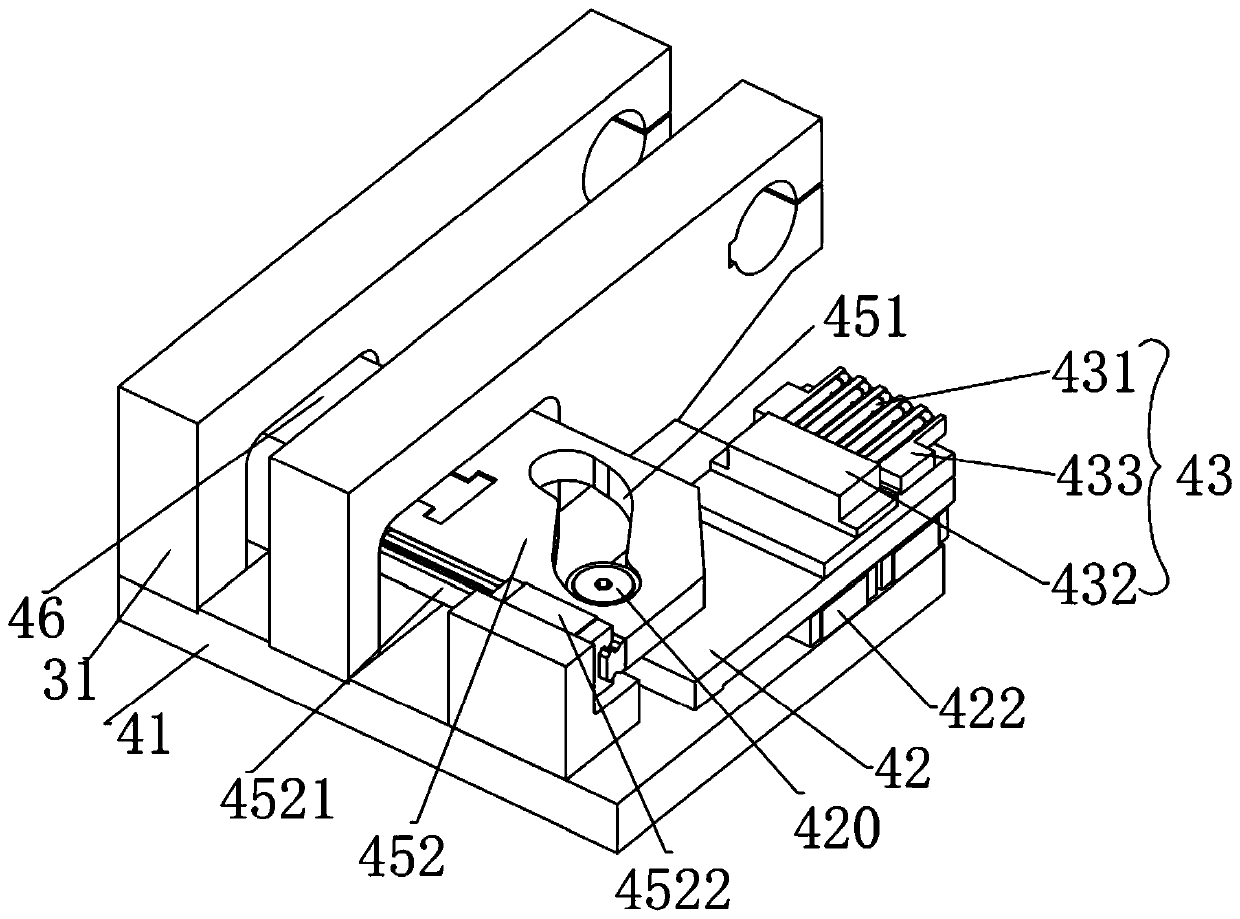

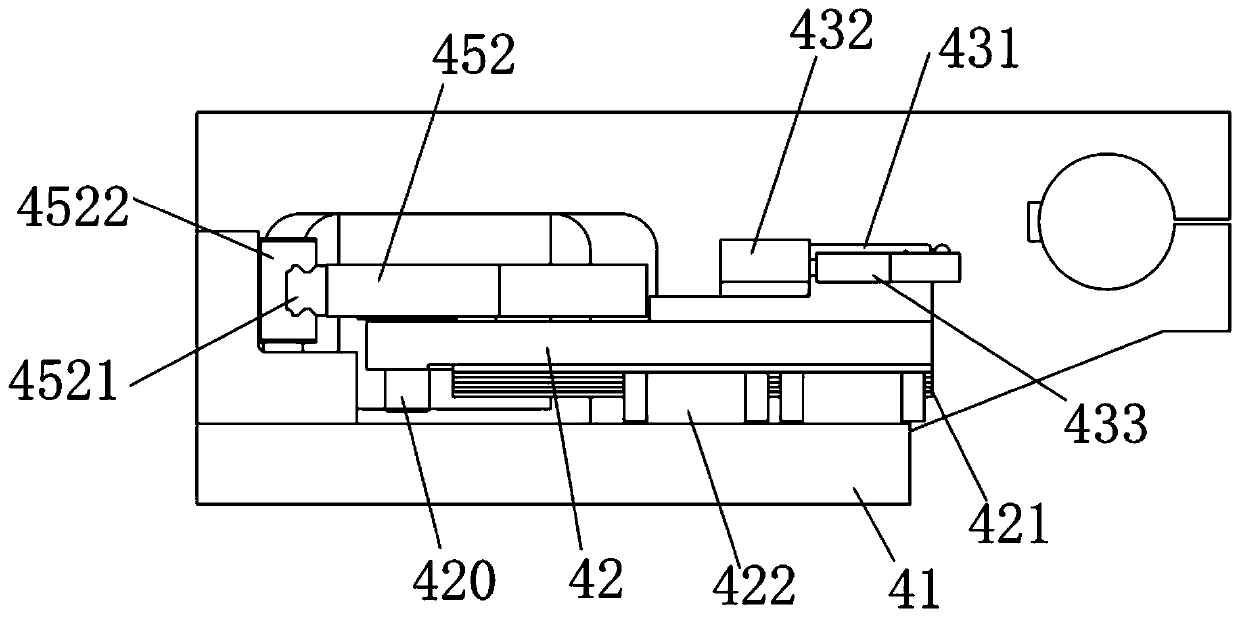

[0027] Such as Figure 1 to Figure 13 as shown, Figure 1 to Figure 13Disclosed is an embodiment of a pneumatic small U pipe bender, a pneumatic small U pipe bender, including a frame 1, on which a bending and clamping mechanism 2, a swing arm 31, a swing arm power mechanism 32 and cutting mechanism 5, the bending and clamping mechanism 2 is used to clamp the workpiece to be bent, the swing arm 31 is hinged with the frame 1 through the swing shaft 30, and the swing arm 31 is driven by the swing arm power mechanism 32 Take the pendulum shaft 30 as the axis to swing toward or away from the bending and clamping mechanism 2, and the cutting mechanism 5 is arranged on one side of the bending and clamping mechanism 2. In the present invention, a core-feeding mechanism 4 is also included. , the core entry mechanism 4 is fixed below the swing arm 31, and is matc

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap