Method for making high-grade custom-made trousers front

A production method and technology of pants are applied in clothing, clothing, application and other directions to achieve the effect of optimizing wearing comfort and wearing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] like Figure 1-4 As shown, the advanced custom trousers placket manufacturing method described in this embodiment, including trousers front piece and zipper, includes the following steps:

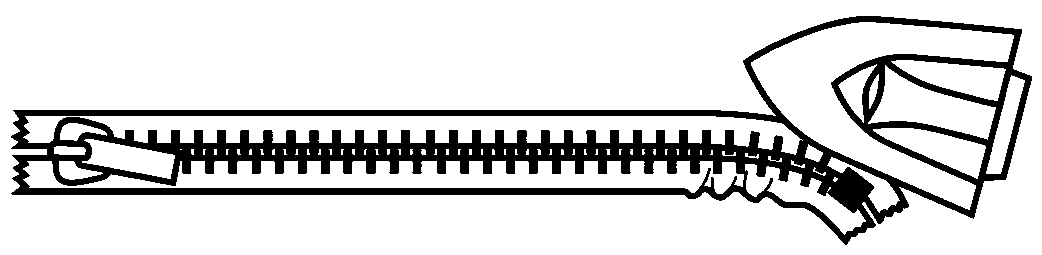

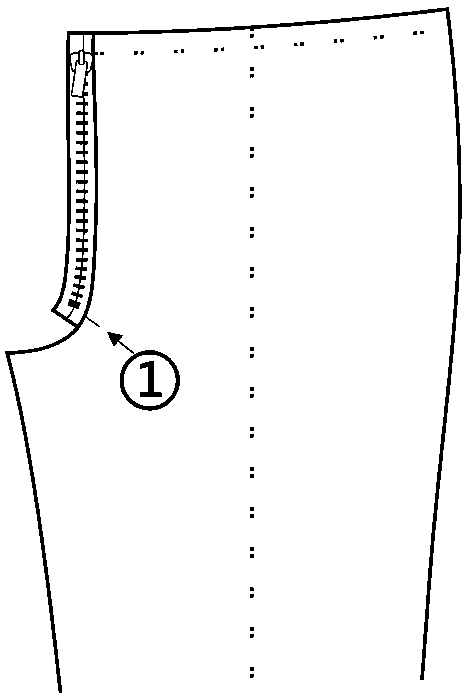

[0016] a) Measure the height of the front waist of the pants worn by the customizer, and design the bottom position of the zipper to be exactly at the bend of the centerline of the front panel of the pants and the front cage door, as in figure 2 Mark ①, and return the curvature at the bottom of the zipper, such as Figure 1-2 shown;

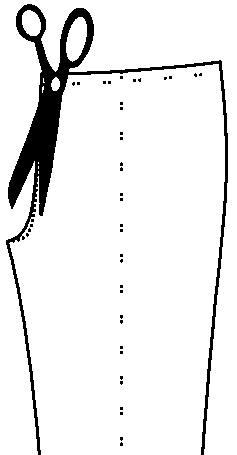

[0017] b) Find out which side of the customizer's reproductive organs are used to store on the left and right, and trim off a unilateral amount of 0.5cm on the side of the front cage door of the pants corresponding to the genitals, such as image 3 shown;

[0018] c) There is a 45-degree slanted wire material on the inner skirt of the trousers that extends the bottom crotch. The width of the slanted wire material is 2.5cm, and the length is the length

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap