Automatic stacking transport line for edible mushroom boxes

A transportation line, automatic technology, applied in the direction of transportation and packaging, conveyor objects, rollers, etc., can solve the problems of mushroom box displacement, mushroom box bumping, poor adjustable performance, etc., to achieve simple structure and reduce production The effect of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

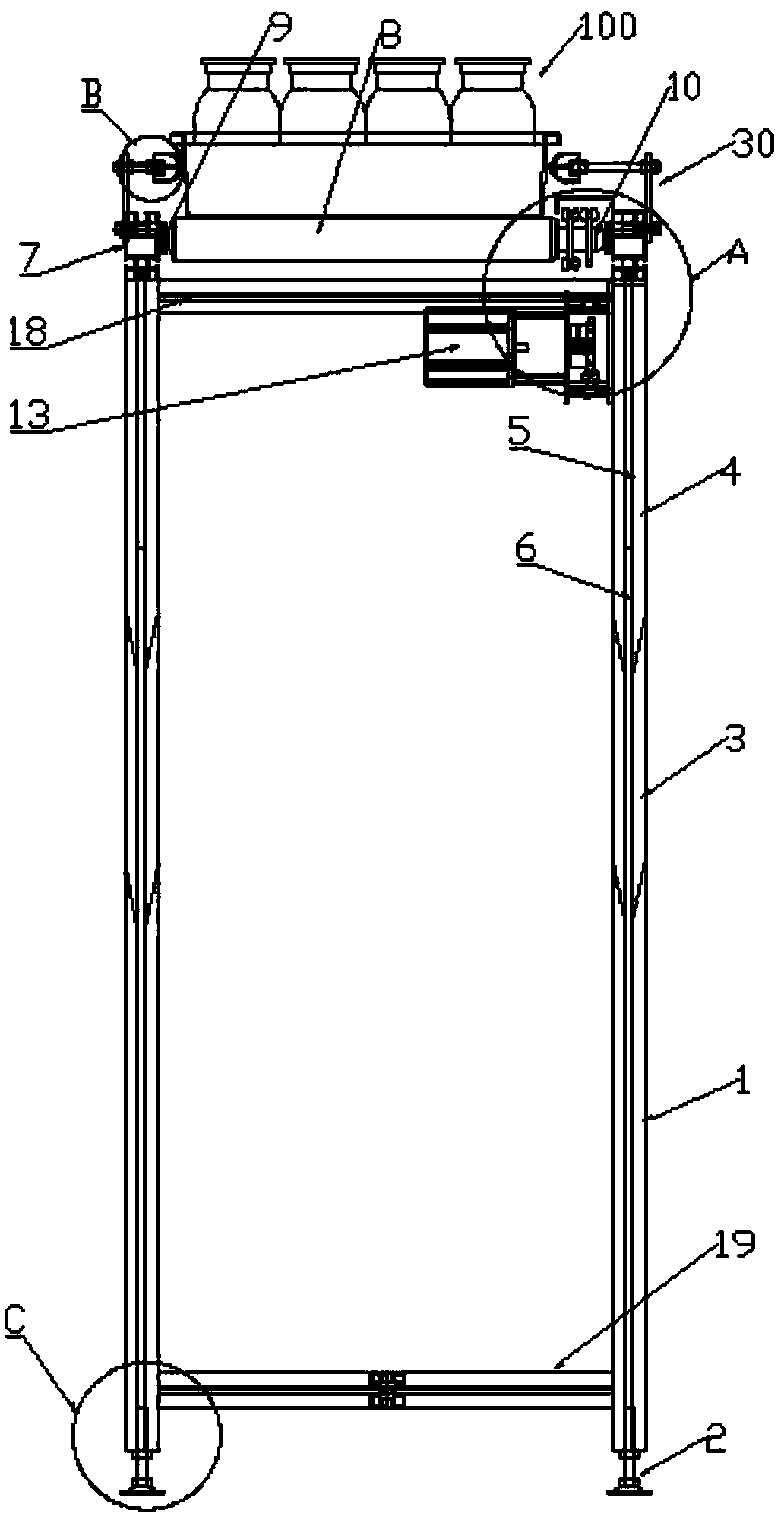

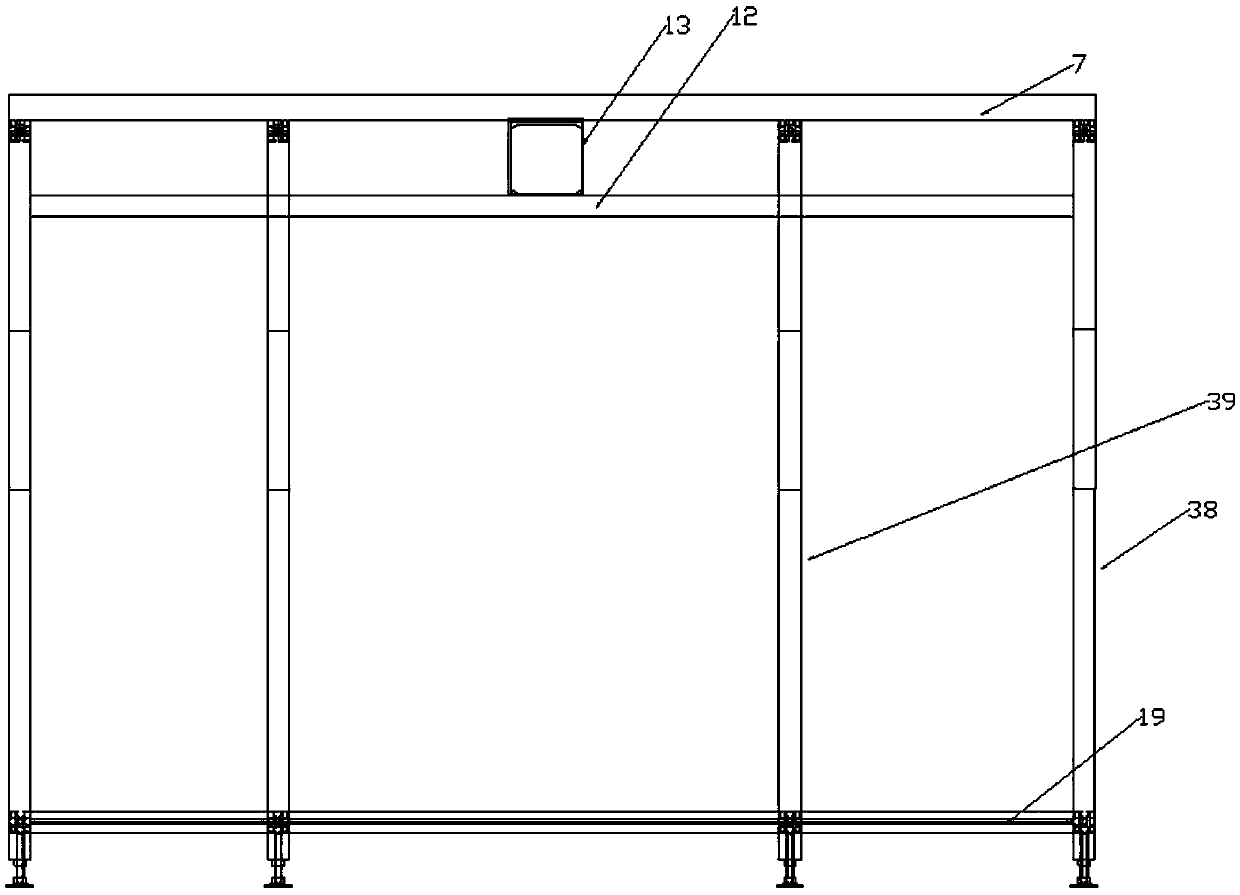

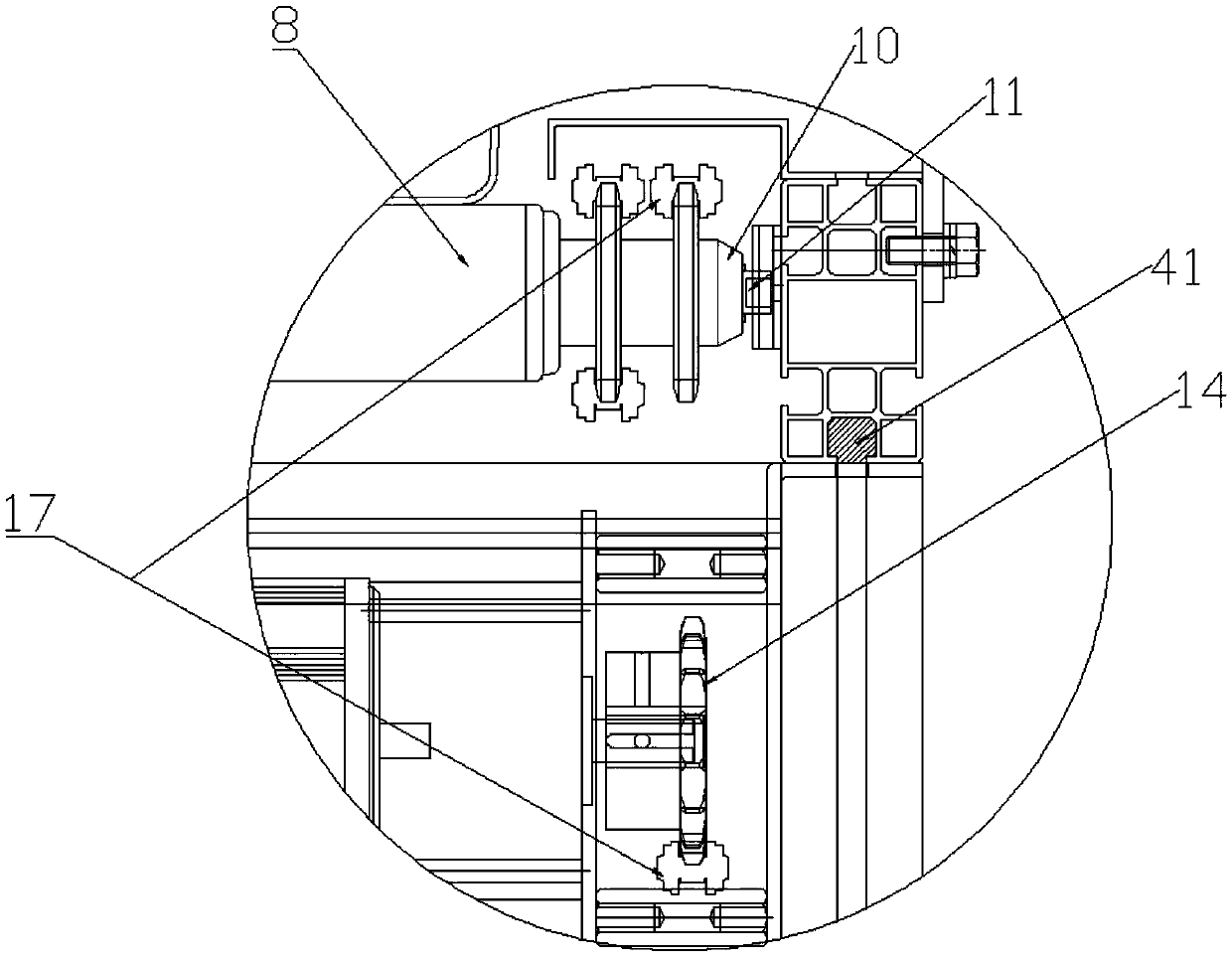

[0024] Figure 1 to Figure 6 The shown automatic palletizing transportation line for edible mushroom boxes, in this embodiment, includes an adjustable conveyor frame and a transport device fixed on the adjustable conveyor frame, and the conveyor frame includes at least one set of four bottoms distributed in a rectangular shape. Support pole 1, adjustable foot 2 fixed on the bottom of bottom support pole 1, middle adjustment rod group 3 connected to bottom support rod 1 and top support rod 4 connected to the top of middle adjustment rod group 3, middle adjustment rod group 3 Including at least one intermediate adjustment rod connected in a straight line, the center of the bottom support rod 1, the middle adjustment rod 3 and the top support rod 4 are all provided with a fixed through hole 5, and a fixed support rod 6 is pierced in the fixed through hole 5, and the fixed support rod One end of 6 abuts against the adjustable leg 2, the other end of the fixed pole 6 is set in the fix

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap