Weeding device for greening

A shell and roller technology, applied in the field of landscaping, can solve problems such as incomplete weeding, and achieve the effect of facilitating sowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is further described in detail through specific implementation methods:

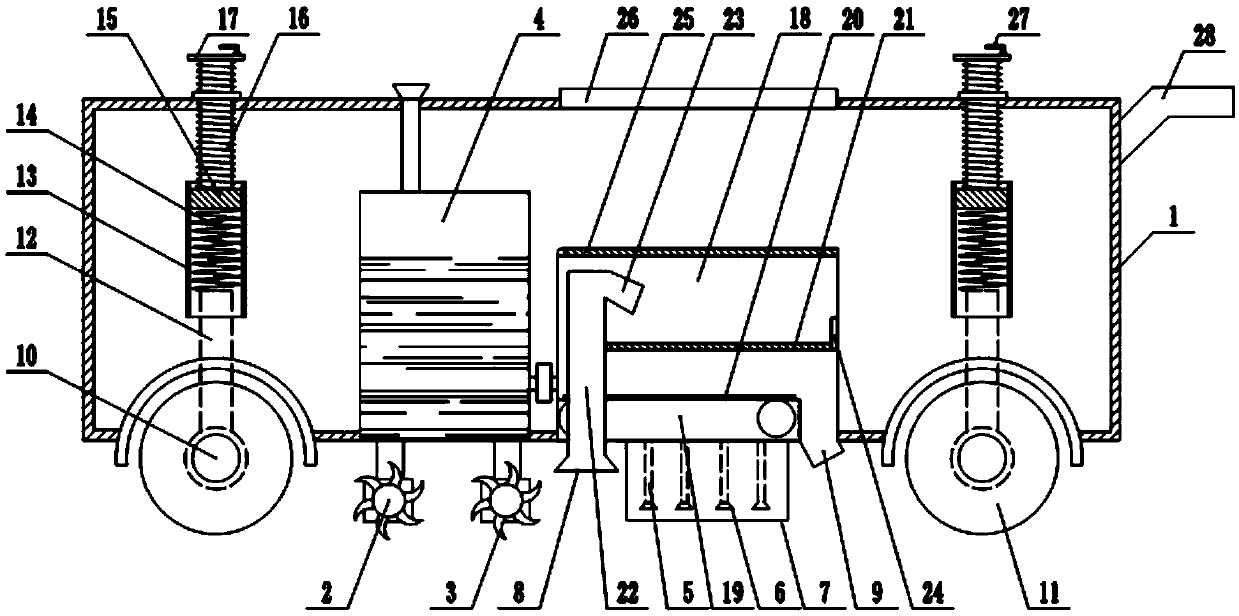

[0026] The reference signs in the drawings of the description include: shell 1, roller shaft 2, cutting knife 3, chemical spray box 4, chemical spray pipe 5, spray head 6, baffle 7, negative pressure feed port 8, discharge port 9 , fixed shaft 10, roller 11, buffer rod 12, buffer cylinder 13, buffer spring 14, buffer block 15, threaded rod 16, turntable 17, screening box 18, transfer table 19, conveyor belt 20, vibrating screen 21, negative pressure Passage 22, discharge pipe 23, baffle plate 24, cover plate 25, material intake port 26, handle 27, push handle 28.

[0027] The embodiment is basically as attached figure 1 Shown: a weeding device for greening, including a housing 1, a traveling mechanism, a weeding mechanism, a screening mechanism and a spraying mechanism.

[0028] The left end of the housing 1 is the mobile front end, the right end of the housing 1 is the mobile rear en

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap