Inductive sensor simulation test method

An analog test, inductive technology, applied in the field of sensor testing, can solve the problems of inconvenient testing, inability to achieve miniaturization, and high development cost of test equipment, reducing complexity and weight, improving integration, and good economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

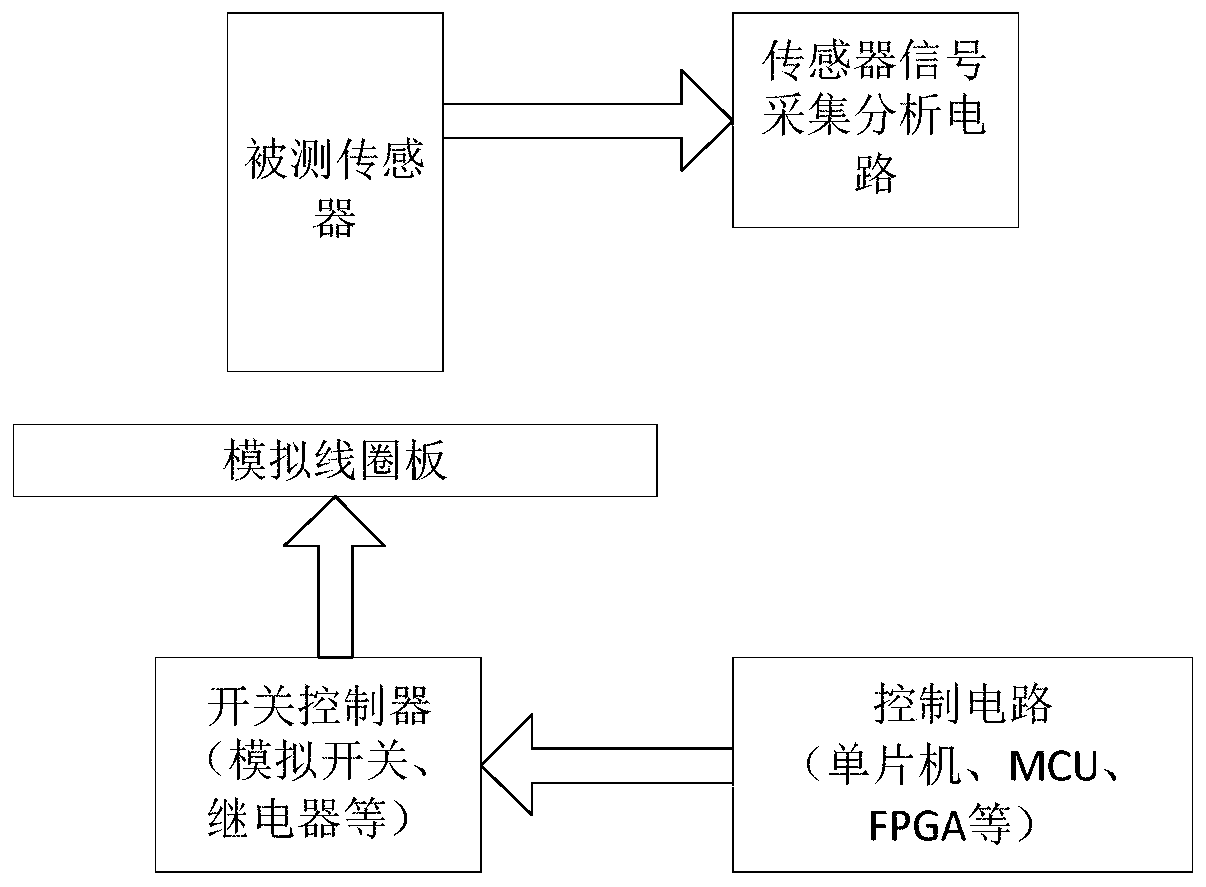

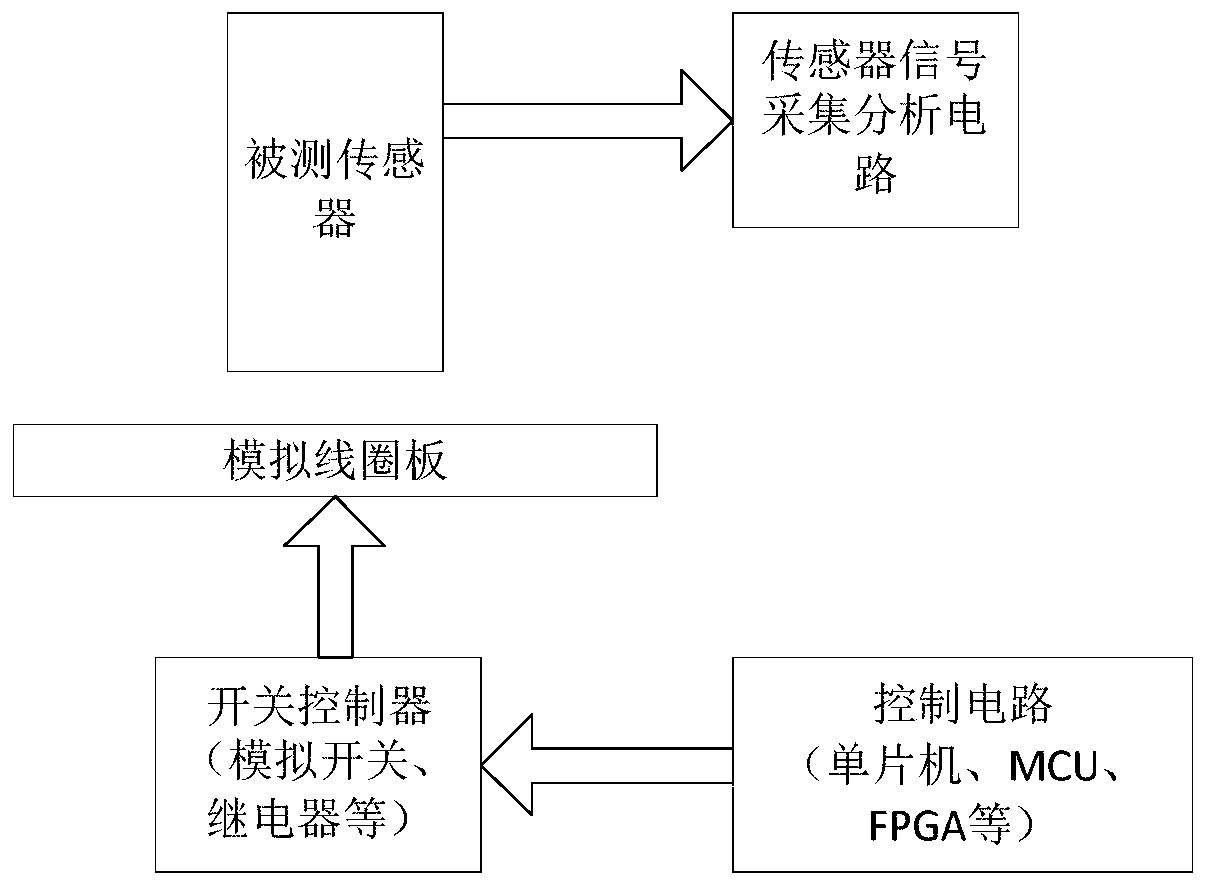

[0020] The following is attached figure 1 The preferred embodiments of the present invention are described, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0021] An inductive sensor simulation test method, comprising the following:

[0022] (1) Design the simulation coil board according to the test requirements, and connect the two ends of the simulation coil on the simulation coil board to the switch controller;

[0023] (2) Design the control circuit to realize the conduction of the analog coil by controlling the switch of the switch controller;

[0024] (3) By controlling the conduction of the analog coil, the analog coil forms a closed coil, and then forms a closed conductor surface on the test end surface of the inductive sensor to simulate the measured object passing through the test end of the inductive sensor;

[0025] (4) Chan

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap