3D printer

A technology of 3D printer and printing device, which is applied in 3D object support structure, additive manufacturing, fastening device of wing fan, etc. It can solve the problems of model bumping and damage, limited door panel size, limited housing space, etc., and reduce the number of molds. Bump and damage, large open area, space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

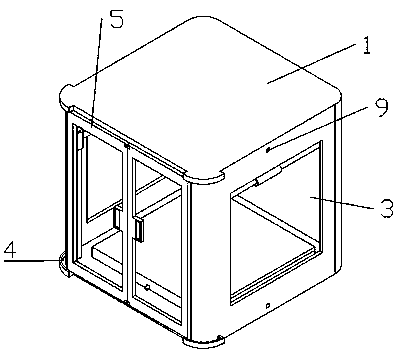

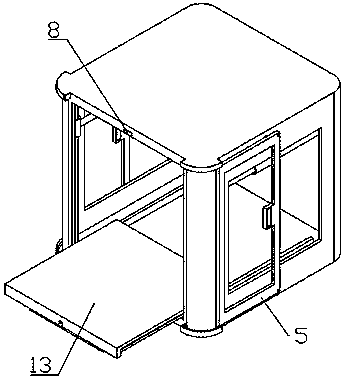

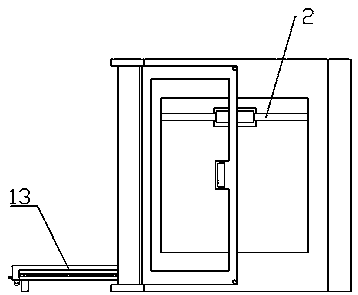

[0020] Such as Figure 1-8 As shown, a 3D printer includes a housing 1, a printing device 2, an observation window 3, an arc groove 4, a door panel 5, a rotating shaft 6, a door panel magnetic sheet 7, a door closing magnetic sheet 8, and a door opening magnetic sheet 9 , support rails 10, rollers 11, positioning slots 12, model carrier 13, the inside of the housing 1 is provided with a printing device 2 that moves along the X, Y, and Z axis directions, and there are observation windows on both sides of the housing 1 3. The four corners of the front of the housing 1 are provided with arc-shaped grooves 4. One end of the door panel 5 is integrally formed with a rotating shaft 6, and the other end is fixed with a door panel magnetic attraction piece 7. The rotating shafts 6 at the upper and lower ends of the door panel 5 are respectively connected

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap