Feeding robot for nanofiber production

A nanofiber and robot technology, applied in the field of robots, can solve the problems of operator's personal safety impact, low degree of automation, low work efficiency, etc., and achieve the effect of optimizing work flow, strong versatility, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

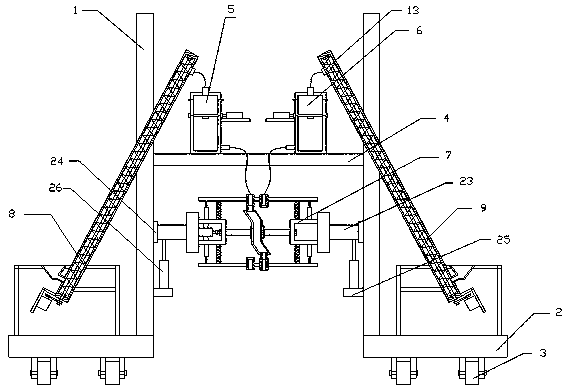

[0046] As shown in the figure, a feeding robot for nanofiber production includes two main support frames 1 arranged parallel to each other, and a bottom support plate 2 is respectively fixed on the bottom of each main support frame, and multiple bottom support plates are arranged on the bottom support plate. Roller 3 with brakes;

[0047] A partition plate 4 is fixed horizontally between the two main support frames, a first material storage tank 5 and a second material storage tank 6 are arranged above the partition plate, and a feeding assembly 7 is provided below the partition plate;

[00

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap