Preparation method of simple substance nano powder through plasma chemical vapor reactions

A technology of chemical gas phase reaction and nano-powder, which is applied in the direction of nano-technology, boron/boride, silicon, etc., can solve the problems of low yield of nano-powder, high impurity content, coldness reduction, etc., and achieve particle size and uniformity Control and ensure the effect of high-purity characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

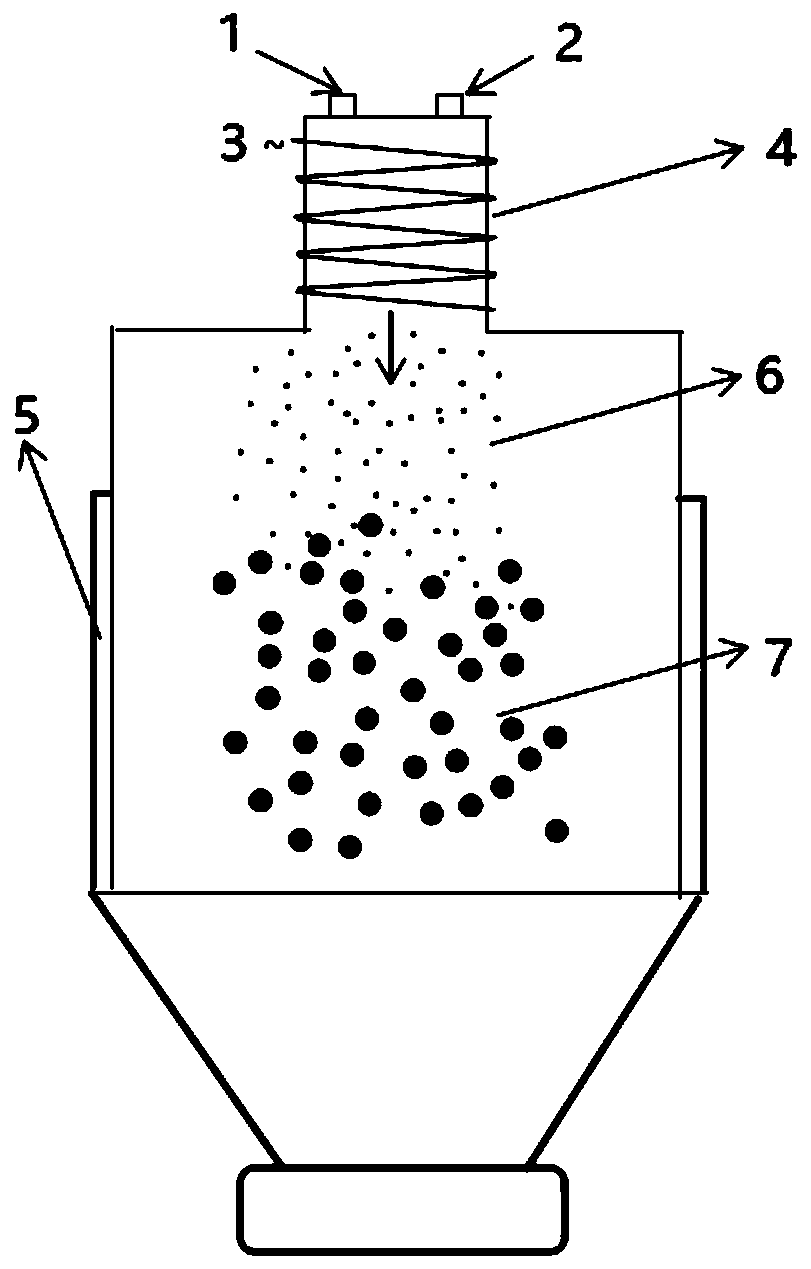

[0022] Plasma chemical gas phase reaction to prepare nano silicon powder, such as figure 1 Shown is the schematic diagram of the technological process that the example of the present invention prepares nano-silicon powder:

[0023] Before the reaction starts, turn on the cooling water of the equipment, feed argon, and set the nitrogen flow rate to 2.7m 3 / h, after the arc strike is stable, set the hydrogen flow rate to 2.0m 3 / h, turn off nitrogen.

[0024] high purity SiCl 4 The raw material is passed into the plasma high-temperature zone, and the plasma power is adjusted to 35kw to make SiCl 4 and H 2 Gas phase reduction reaction occurs: SiCl 4 +H 2 →Si+HCl, the generated high-purity silicon vapor passes through the cooling zone under the action of argon, the temperature of the cooling zone is set to 30°C, the corresponding powder is formed through condensation nucleation, and finally the corresponding powder is obtained through the powder separation and collection de

Embodiment 2

[0027] Preparation of nano boron powder by plasma chemical vapor reaction.

[0028] Before the reaction starts, turn on the cooling water of the equipment, feed argon, and set the nitrogen flow rate to 3.0m 3 / h, after the arc strike is stable, set the hydrogen flow rate to 2.0m 3 / h, turn off nitrogen.

[0029] high purity BCl 3 The raw material is passed into the plasma high-temperature zone, and the plasma power is adjusted to 38kw to make the BCl 3 and H 2 A gas phase reduction reaction occurs: BCl 3 +H 2 →B+HCl, the generated high-purity boron vapor passes through the cooling zone under the action of argon, the temperature of the cooling zone is set to 25°C, the corresponding powder is formed through condensation nucleation, and finally the corresponding powder is obtained through the powder separation and collection device. of nanopowders.

[0030] The boron content of the prepared nano boron powder is 99.9%, and the particle size of the nano boron powder is 50-8

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap