Low-speed large torque permanent magnet motor drive system for small space

A permanent magnet motor and drive system technology, applied in the direction of electric components, connected with control/drive circuits, electrical components, etc., can solve the problems of inconvenient installation and transportation, complex generator structure, high manufacturing cost, etc., and improve the utilization rate of materials , save material cost, and facilitate installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0034] Embodiment one:

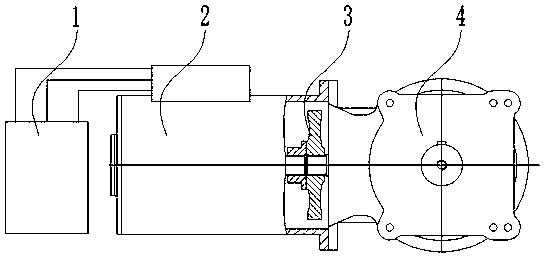

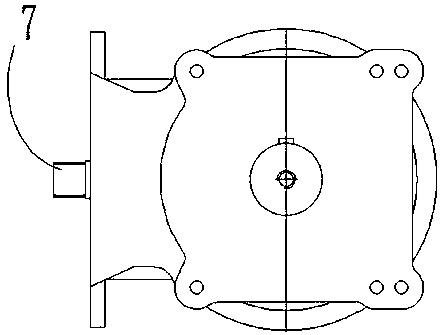

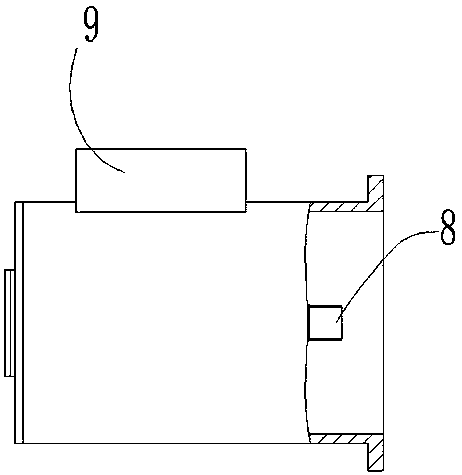

[0035]A low-speed, high-torque permanent magnet motor drive system for a small space, including a motor, a right-angled shaft reducer 4 movably coupled to the output shaft of the motor, and a frequency converter 1 flexibly connected to the motor. The motor is Low-speed high-torque permanent magnet synchronous motor 2, the output shaft of the low-speed high-torque permanent magnet synchronous motor 2 forms an angle of 90 degrees with the output shaft of the right-angle shaft reducer 4, and the output shaft of the low-speed high-torque permanent magnet synchronous motor 2 end and the input shaft end of the orthogonal shaft reducer 4 are connected by a spline coupling 3, the casing of the low-speed high-torque permanent magnet synchronous motor 2 is connected with the casing of the rectangular axis reducer 4, and the The machine 4 is a single-stage reducer, the middle part of the top of the low-speed high-torque permanent magnet motor is provided with an int

Example Embodiment

[0036] Embodiment two:

[0037] A low-speed, high-torque permanent magnet motor drive system for a small space, including a motor, a right-angled shaft reducer 4 movably coupled to the output shaft of the motor, and a frequency converter 1 flexibly connected to the motor. The motor is Low-speed high-torque permanent magnet synchronous motor 2, the output shaft of the low-speed high-torque permanent magnet synchronous motor 2 forms an angle of 90 degrees with the output shaft of the right-angle shaft reducer 4, and the output shaft of the low-speed high-torque permanent magnet synchronous motor 2 end and the input shaft end of the orthogonal shaft reducer 4 are connected by a spline coupling 3, the casing of the low-speed high-torque permanent magnet synchronous motor 2 is connected with the casing of the rectangular axis reducer 4, and the The machine 4 is a single-stage reducer, the output shaft end of the low-speed high-torque permanent magnet synchronous motor 2 is provided wi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap