Space-adjustable anti-extrusion conveying device for storing OLED (Organic light emitting diode) material

A transport device, adjustable technology, used in transport and packaging, multi-axis trolleys, trolley accessories, etc., can solve problems such as surface damage, and achieve the effect of reducing mutual extrusion and collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

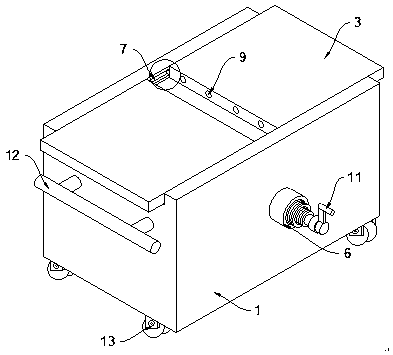

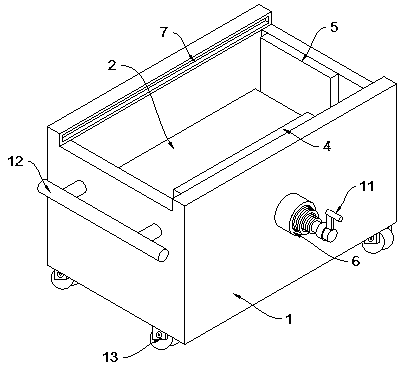

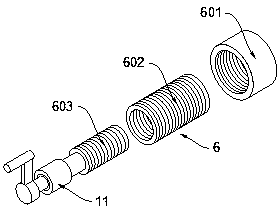

[0023] Example: such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the present invention is an adjustable space anti-extrusion transportation device for storing OLED materials, including a storage box 1 and a storage board 2 placed in the storage box 1, and both sides of the top of the storage box 1 are movable. 3. The top of the inner cavity of the storage box 1 is provided with a first elastic plate 4, and the top of one side of the inner cavity of the storage box 1 is equipped with a second elastic plate 5. The placement of the first elastic plate 4 and the second elastic plate 5 outside The box 1 is provided with a push mechanism 6, the push mechanism 6 includes a fixed seat 601, a threaded barrel 602 and a threaded rod 603, the fixed seat 601 is fixedly connected with the placement box 1, and the threaded barrel 602 is placed in the fixed seat 601 and threaded with it, And one end of the two threaded cylinders 602 passes through the placement bo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap