Cotton fiber roll automatic dismounting device

An automatic dismantling and cotton fiber technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult cleaning of cotton fibers, easy loss of cotton fibers, low disassembly efficiency, etc. The effect of short disassembly time and gentle disassembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

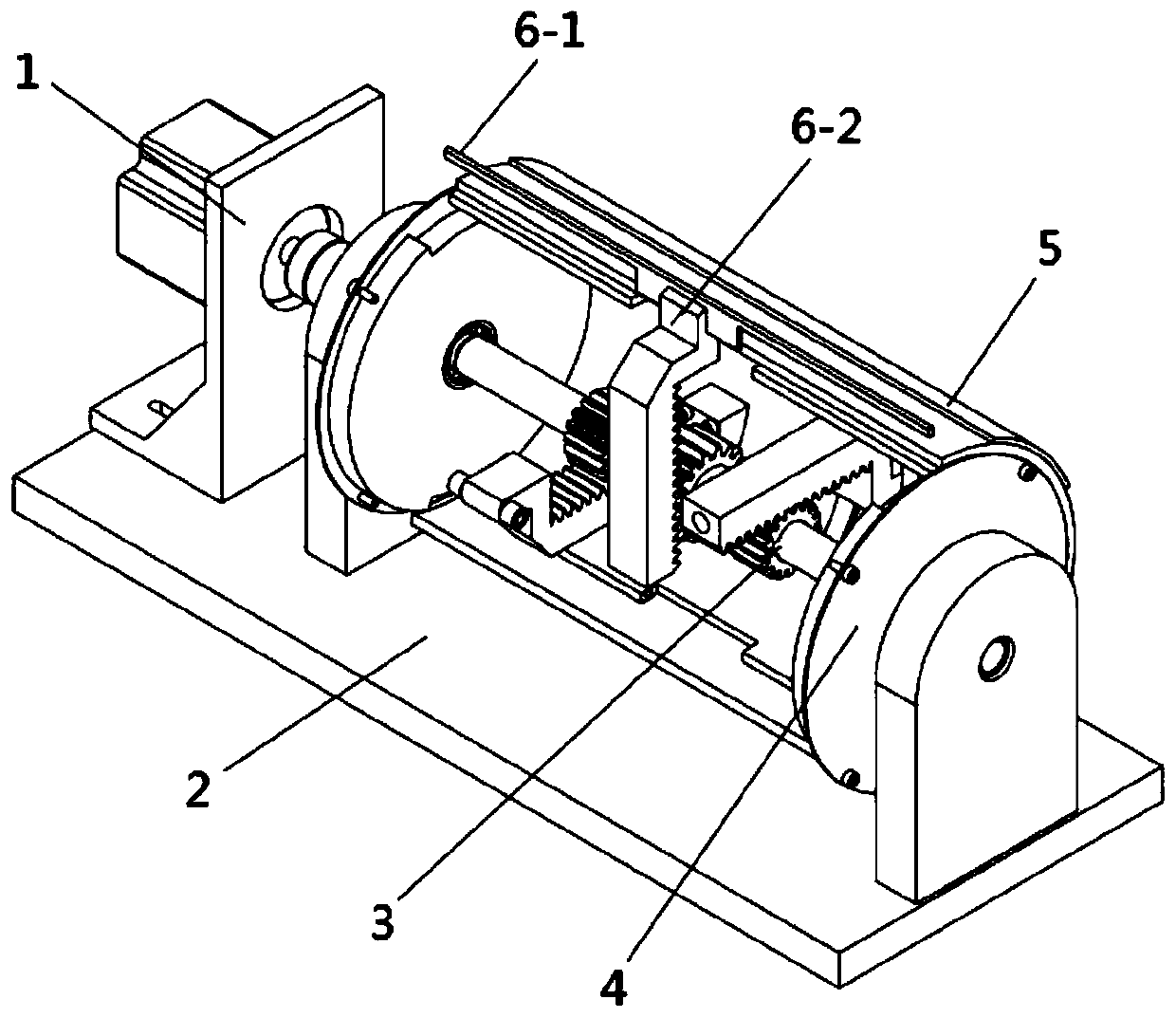

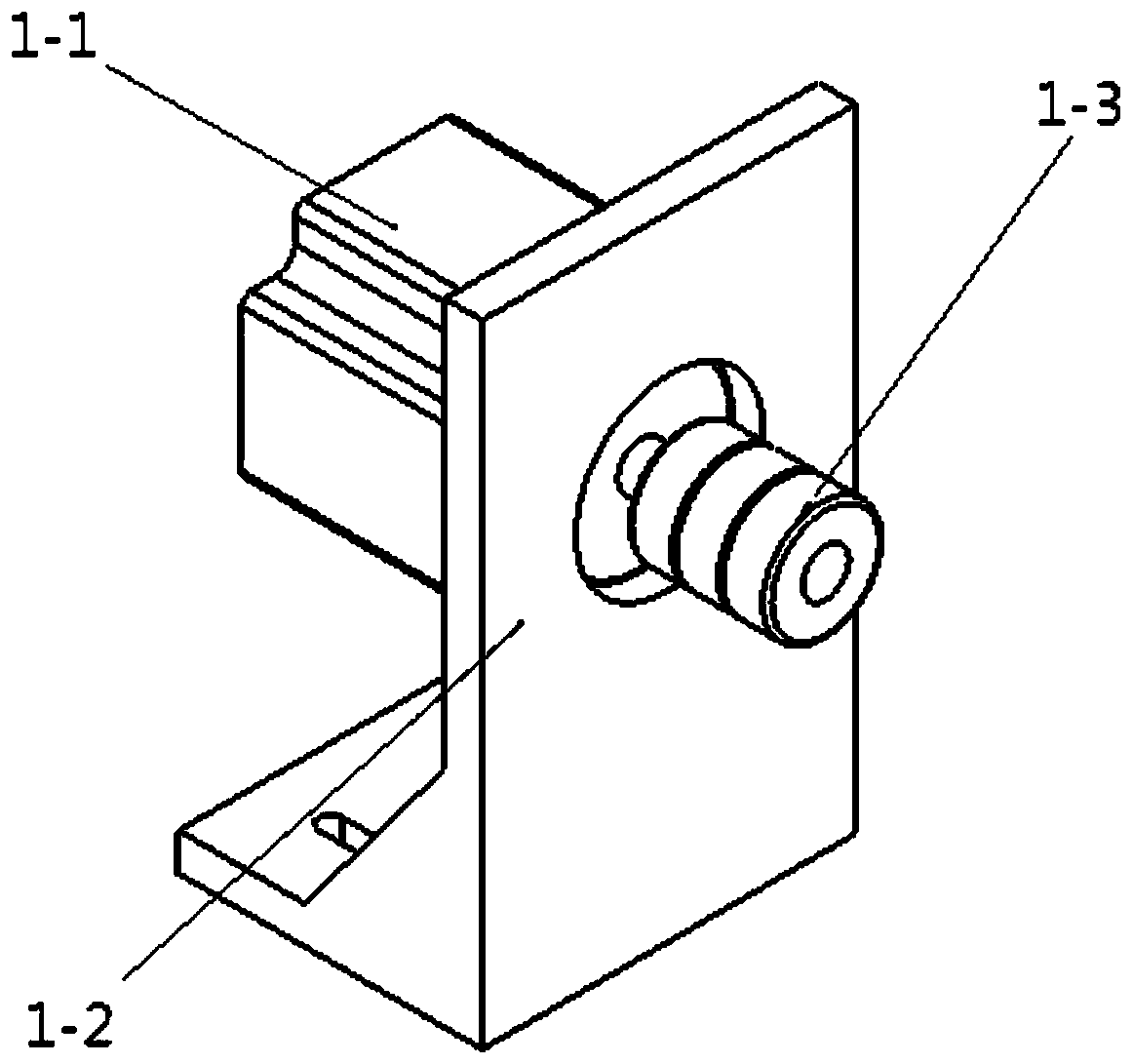

[0035] Please also refer to Figure 1 to Figure 13 , the cotton fiber roll automatic detaching device provided by the present invention is now described. The automatic dismantling device for cotton fiber rolls is an instrument for testing textile materials, which is not equivalent to textile production equipment. Dismantling of fiber rolls; including:

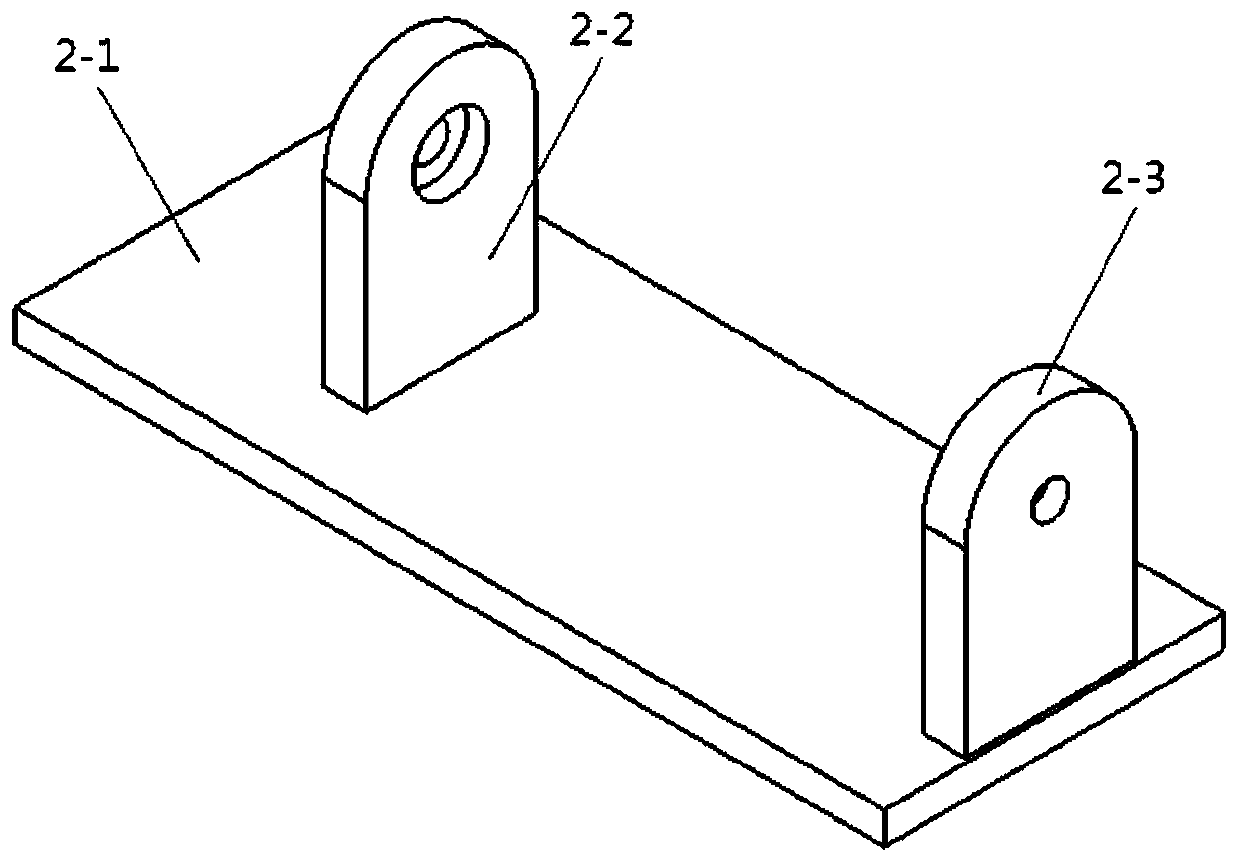

[0036] rack assembly 2;

[0037] The cotton picking mechanism 6 is used to pick apart the cotton fiber roll 7. The cotton picking mechanism 6 includes a sharp plate 6-1 and is arranged on the frame assembly 2 and is

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap