Self-locking fiber reinforced polymer (FRP) profile beam-column joint capable of being fabricated quickly

A beam-column joint and self-locking technology, which is applied in the direction of architecture and building construction, can solve the problems of reduced column bearing capacity, complex structure, and difficult pouring, so as to improve construction efficiency, good tensile performance, and high degree of industrialization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] The present invention will be further described below in conjunction with the drawings and embodiments.

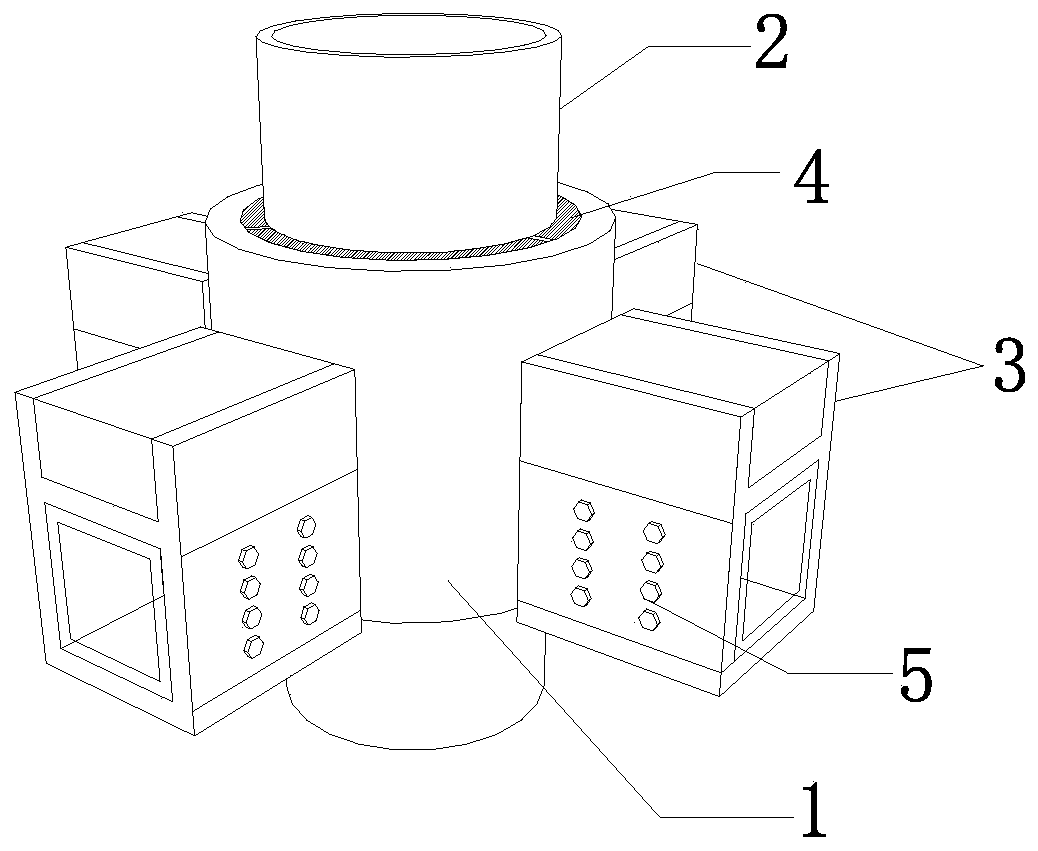

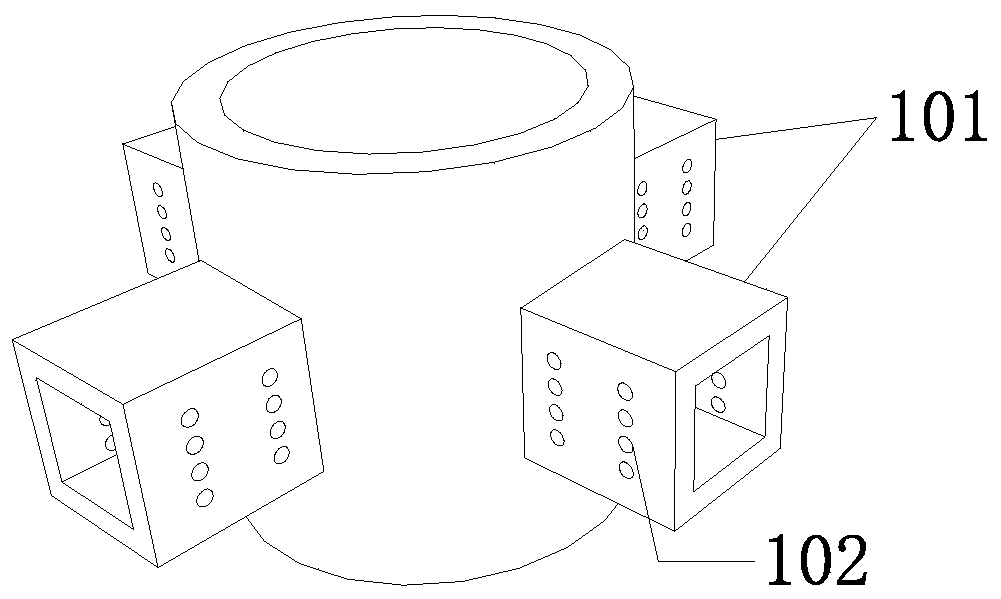

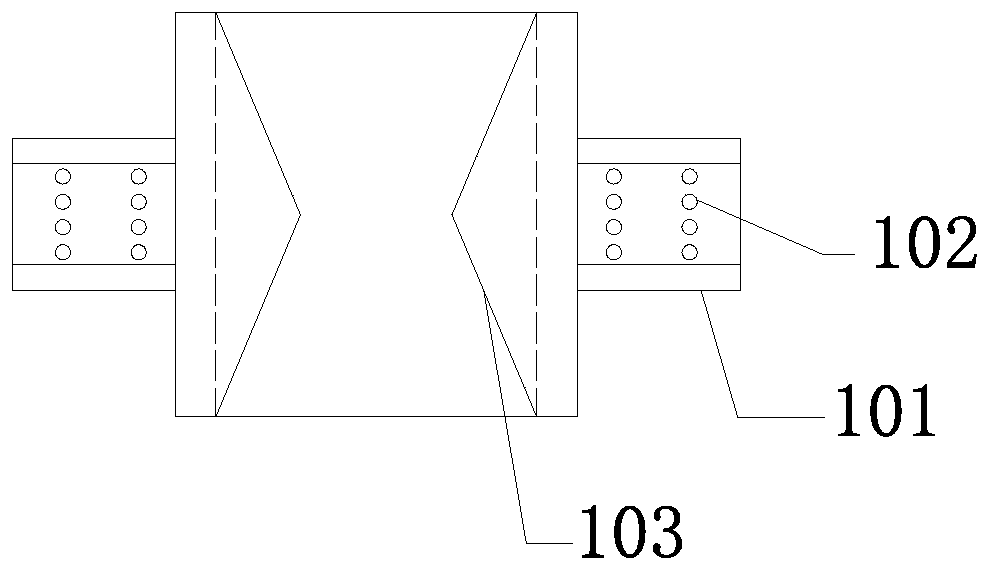

[0030] As shown in the figure, the self-locking FRP profile beam-column node that can be quickly assembled includes prefabricated node 1 and circular FRP tube concrete column 2; prefabricated node 1 is an integrated node, and the inner wall of prefabricated node 1 is connected to circular FRP tube concrete The outer wall of the column 2 is sleeved; the precast node 1 is vertically provided with a bidirectional conical hole 103, the bidirectional conical hole 103 is provided with a node conical surface, and the bidirectional conical hole 103 is sleeved in the circular FRP tube concrete column 2;

[0031] A clip assembly 4 is provided under the bidirectional conical hole 103 for fixing; the clip assembly 4 is a conical shape surrounded by the same three clips and matched with the conical surface of the node. The inner side of the clip assembly 4 is provided with a thread to in

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap