Method for measuring radial expansion force during running of cable middle joint

A technology of cable intermediate joints and radial expansion, which is applied in measuring devices, force/torque/power measuring instruments, instruments, etc., can solve problems such as short circuit or interface arc, casualties, partial discharge, etc., and reduce fire and explosion of cable joints accidents, improve power supply reliability, and reduce the effects of maintenance tests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

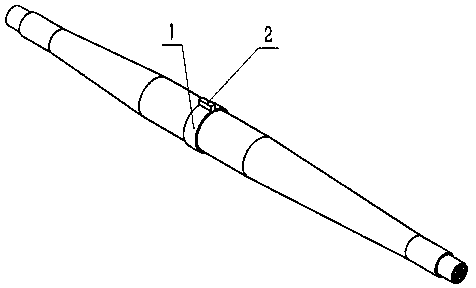

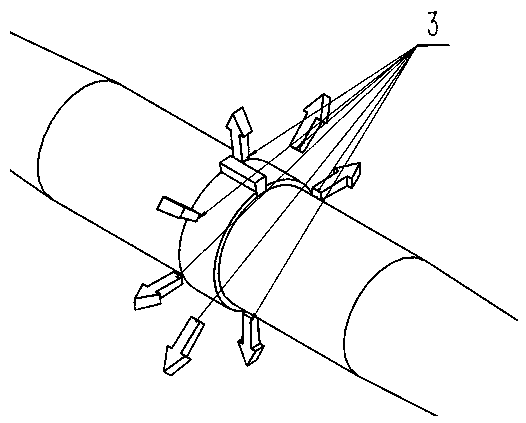

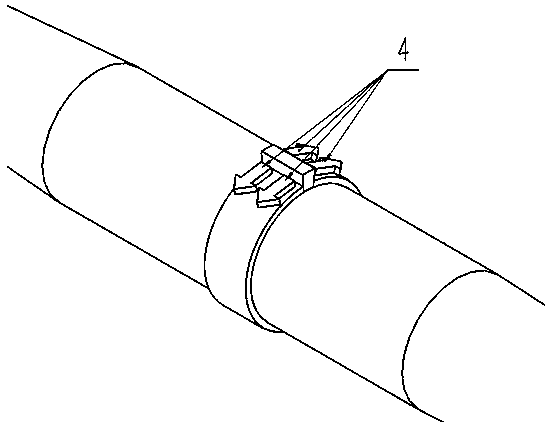

[0016] Such as figure 1 As shown, this embodiment provides a method for measuring the radial expansion force of the cable intermediate joint during operation, including an open ring sleeve wound on the cable intermediate joint and a mechanical sensor connected in series at the opening of the ring sleeve;

[0017] The open ring sleeve wound on the cable intermediate joint is used to bear the expansion force when the joint radially expands and convert the radial expansion force into a circumferential pulling force and transmit it to the mechanical sensor due to its incapable or micro-deformable nature; the series connection The mechanical sensor at the opening of the ring is used to collect the circumferential tension transmitted from the ring and has force value display and over-threshold alarm functions. After the installation is completed, the reading is artificially reset to zero and an early warning threshold is set. For the installation of the ring sleeve and the sensor, the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap