Robot plane work point rapid positioning system and rapid positioning method thereof

A positioning system and operating point technology, applied in the field of robots, can solve the problems of on-site debugging, time-consuming calibration, many operating points, long cycle, etc., and achieve the effect of simple distribution of operating points, simple operating trajectory, and high degree of freedom.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation of the invention will be further described below in conjunction with the accompanying drawings.

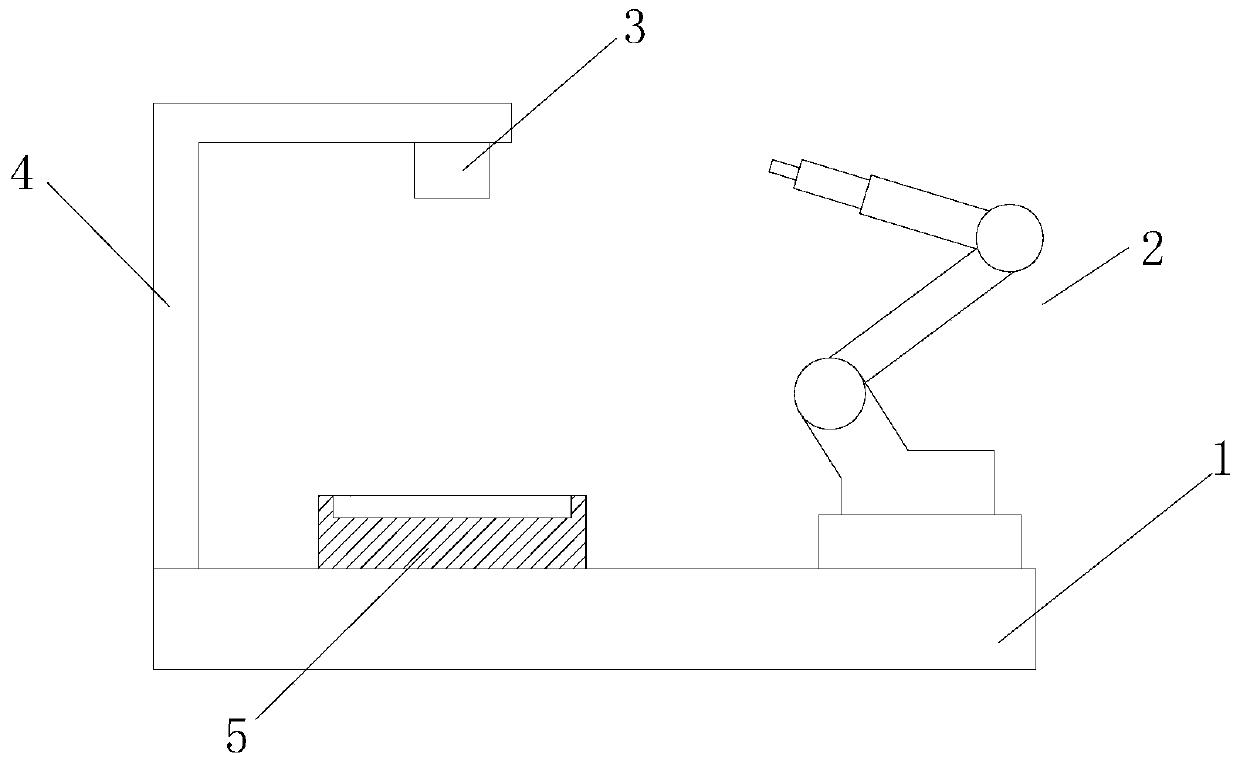

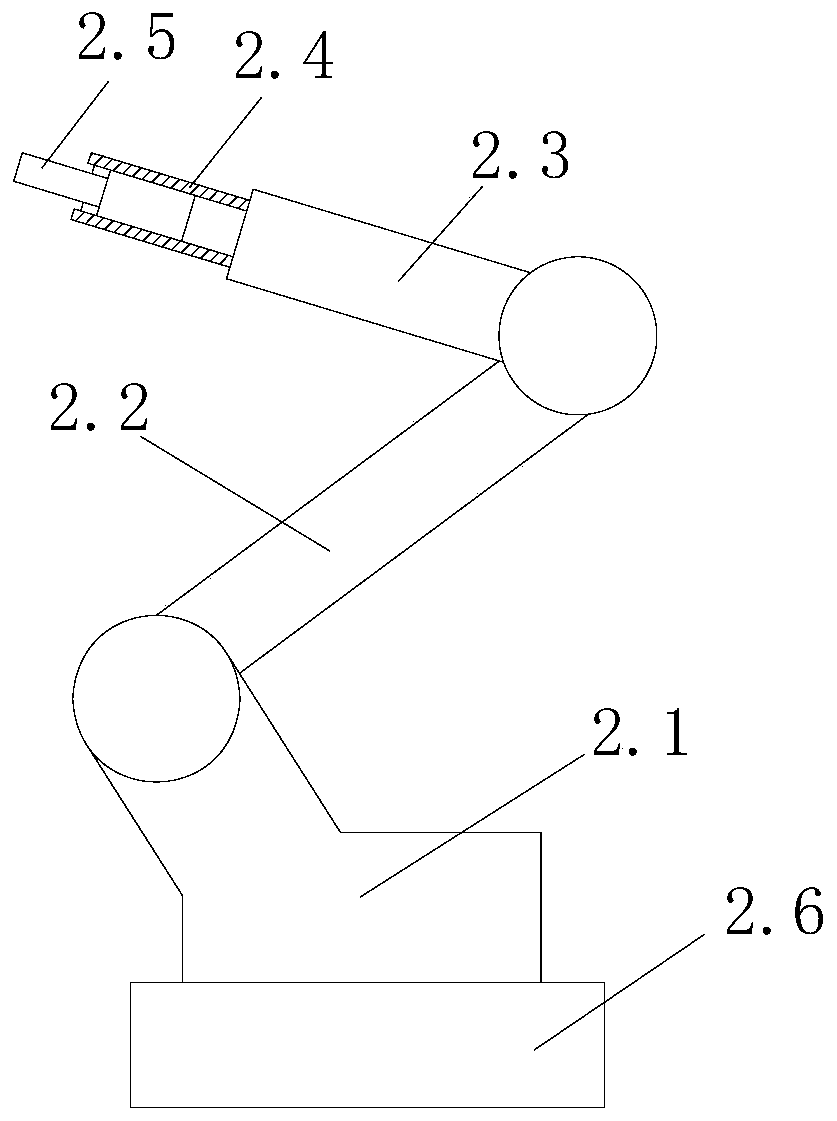

[0033] Such as figure 1 Shown is a robot plane operating point rapid positioning system, including a workbench 1, a camera 3, a robot body 2, a control device and a host computer.

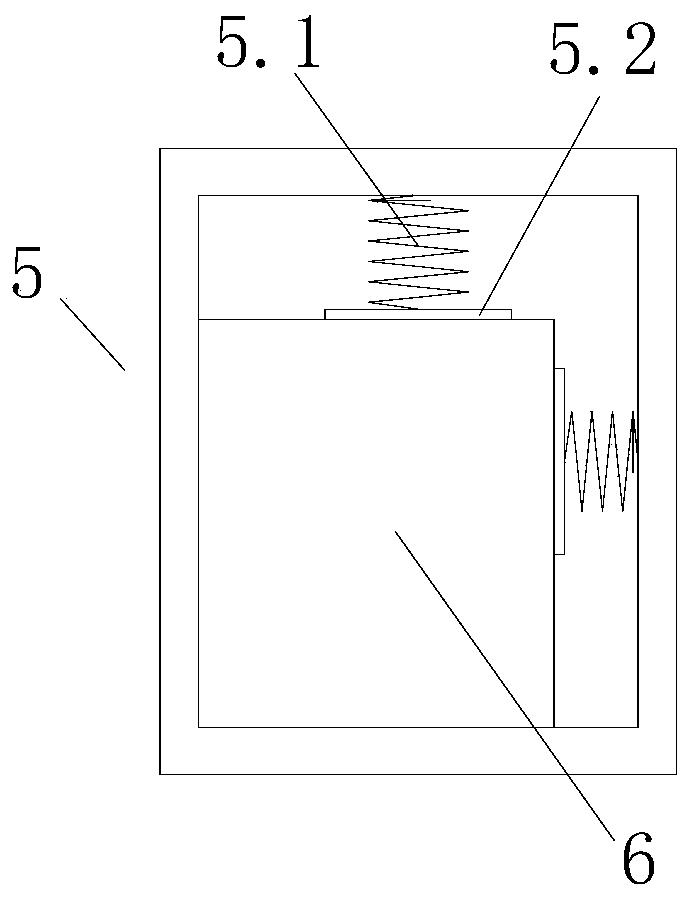

[0034] Workbench 1 top surface is provided with workpiece placement part 5; Camera 3 is installed on workbench 1 top surface by support 4, and support 4 in the present embodiment is universal support, and described camera 3 is positioned at the top of workpiece placement part 5 and its The lens faces the workpiece placing part 5 . The workpiece placement part 5 includes a rectangular placement groove, two fixed blocks 5.2 and two springs 5.1, and the two fixed blocks 5.2 are arranged in the placement groove, and the two fixed blocks 5.2 pass through a spring 5.1 and the placement groove respectively. Two of the adjacent side walls are connected, a plate-shaped workpiec

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap