Wheel set mechanism of track wheel with efficient damping function

A technology for wheel sets and tracks, which is applied to tracked vehicles, motor vehicles, transportation and packaging, etc., can solve problems such as poor shock absorption, aggravate vehicle body vibration, and inability to adjust, achieve good shock absorption and reduce ground Impact force, the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] The present invention will be further explained below in conjunction with the drawings.

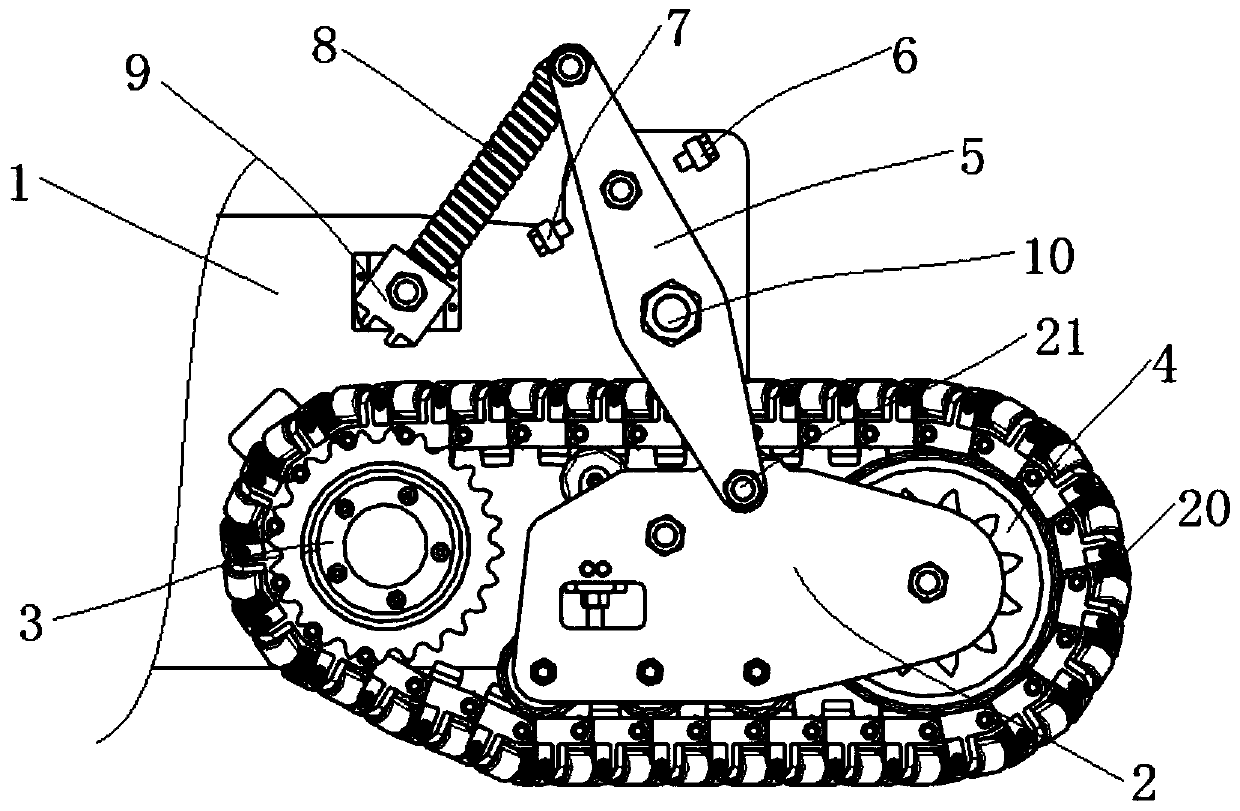

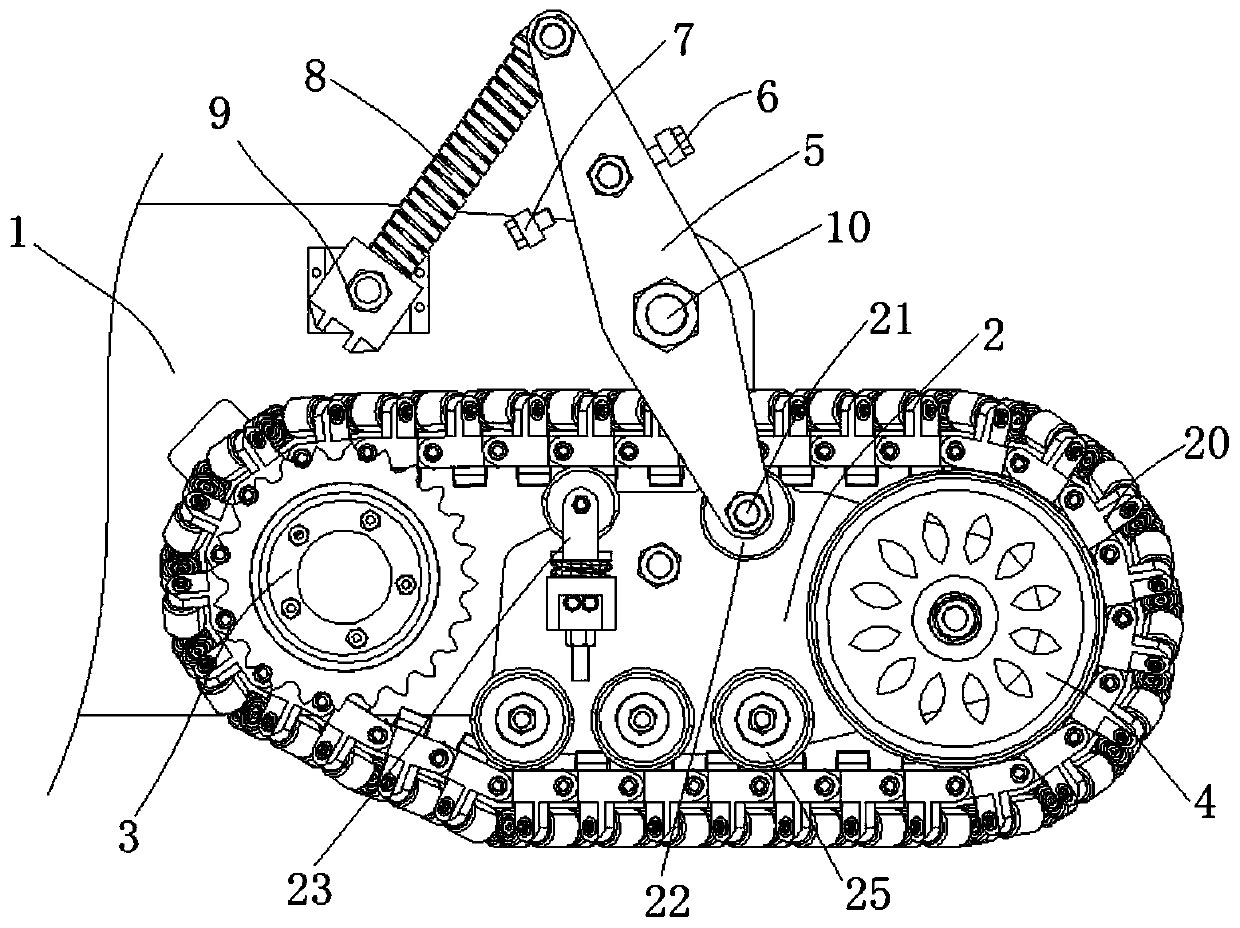

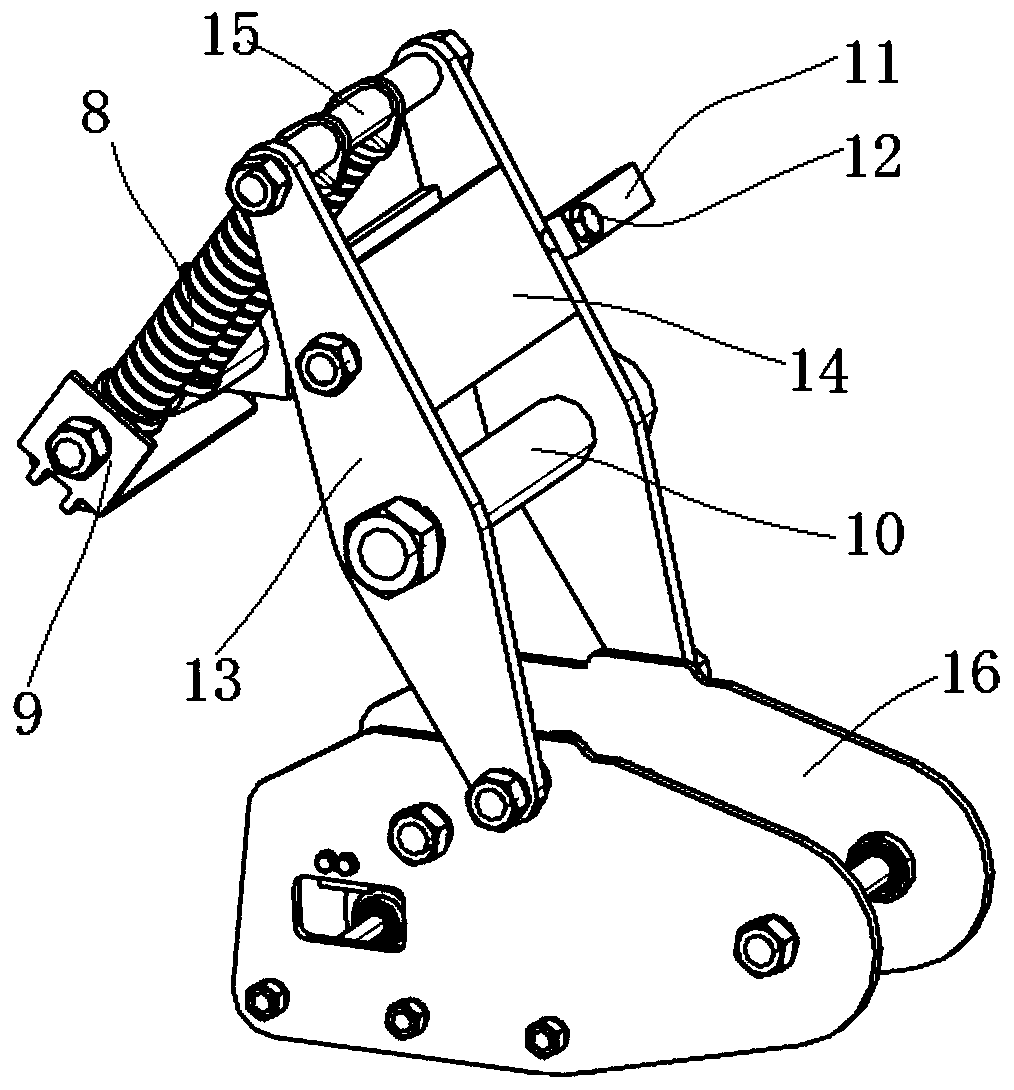

[0022] As attached figure 1 Attached Figure 4 As shown, an efficient shock-absorbing crawler wheel set mechanism includes a frame 1, a wheel frame 2, a driving wheel 3, a road wheel 4, a shock-absorbing arm 5, and an elastic connecting member 8. The driving wheel 3 is rotatably arranged On the frame 1, the road wheels 4 are rotatably arranged on the wheel frame 2 through the crawler belt 20, the damping arm 5 is inclined to the traveling direction of the vehicle body, and the part between the two ends of the damping arm 5 passes through the shaft 10 is rotatably arranged on the frame 1, the rotation plane of the damping arm 5 is a vertical plane, the rotation axis direction of the damping arm 5 is the same as the rotation axis direction of the wheel, and the rotation shaft 10 is fixed to the wheel frame 2 on the upper frame, and one end of the damping arm 5 is connected to the wheel fra

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap