Voltage-withstanding high-power LED lamp array

An LED lamp bead, high-power technology, applied in the cooling/heating devices of lighting devices, lighting and heating equipment, semiconductor devices of light-emitting elements, etc. The effect of heat dissipation and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following describes specific embodiments of the present invention.

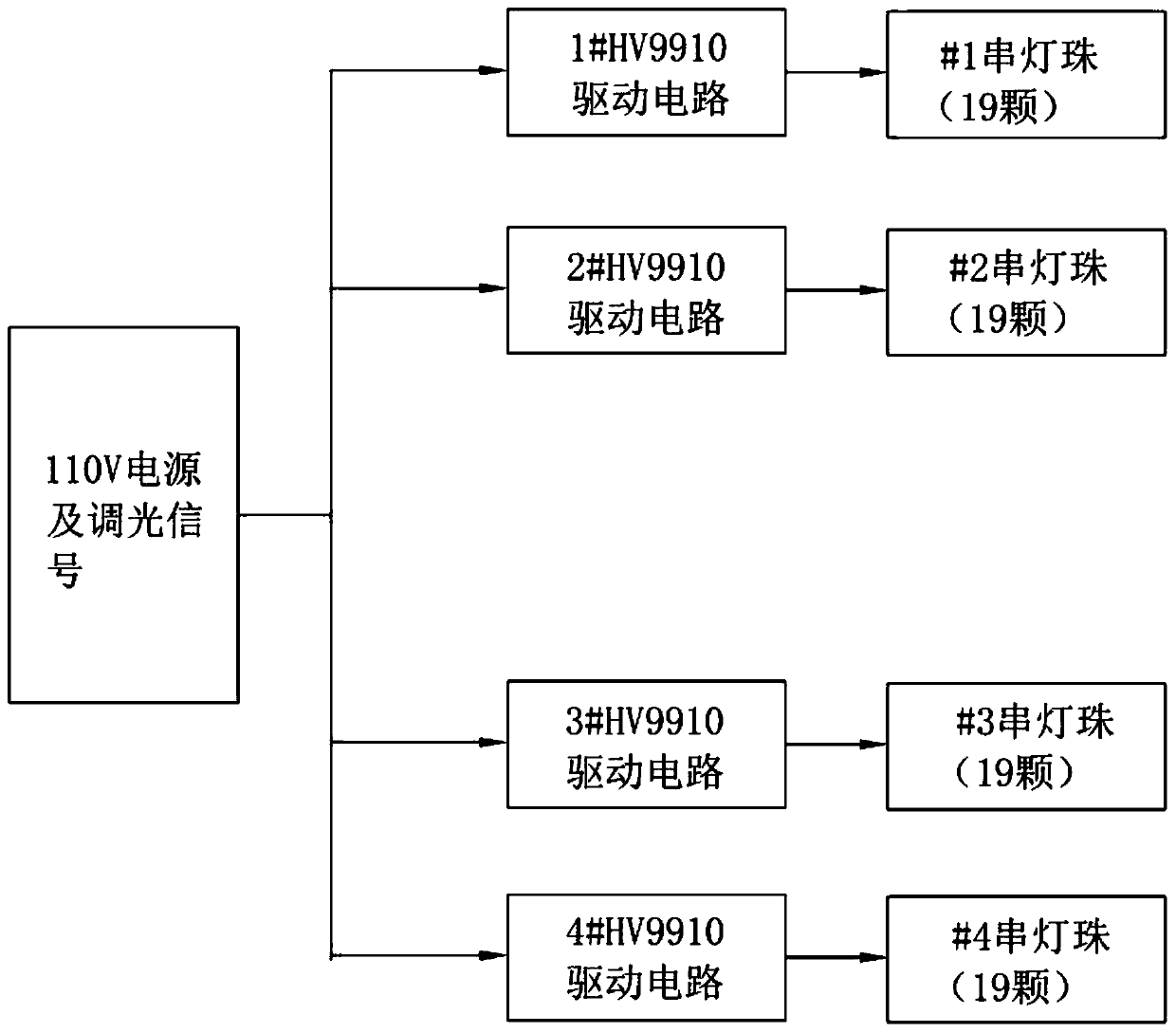

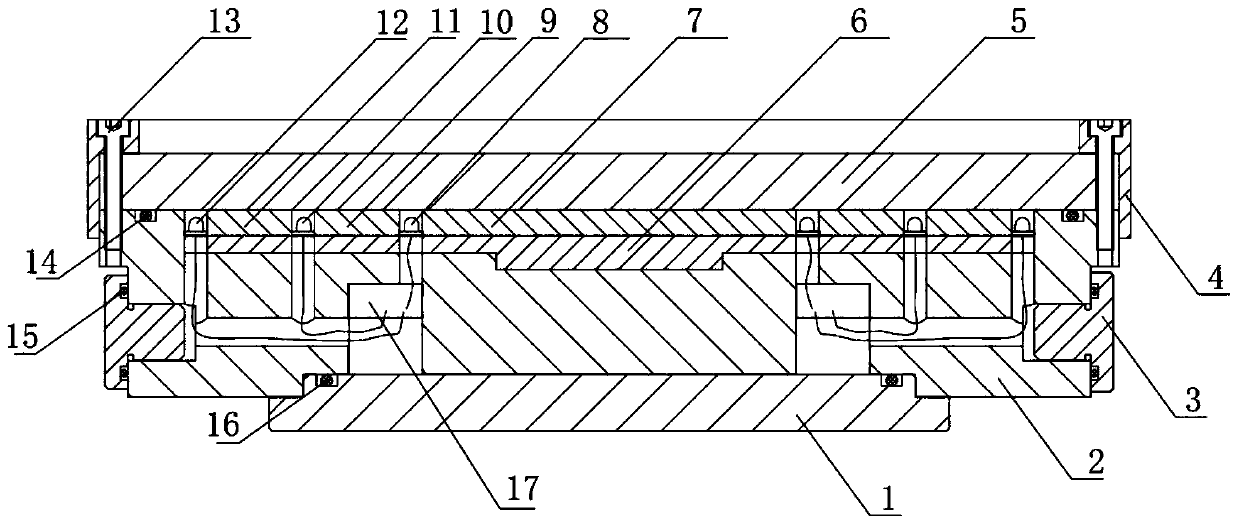

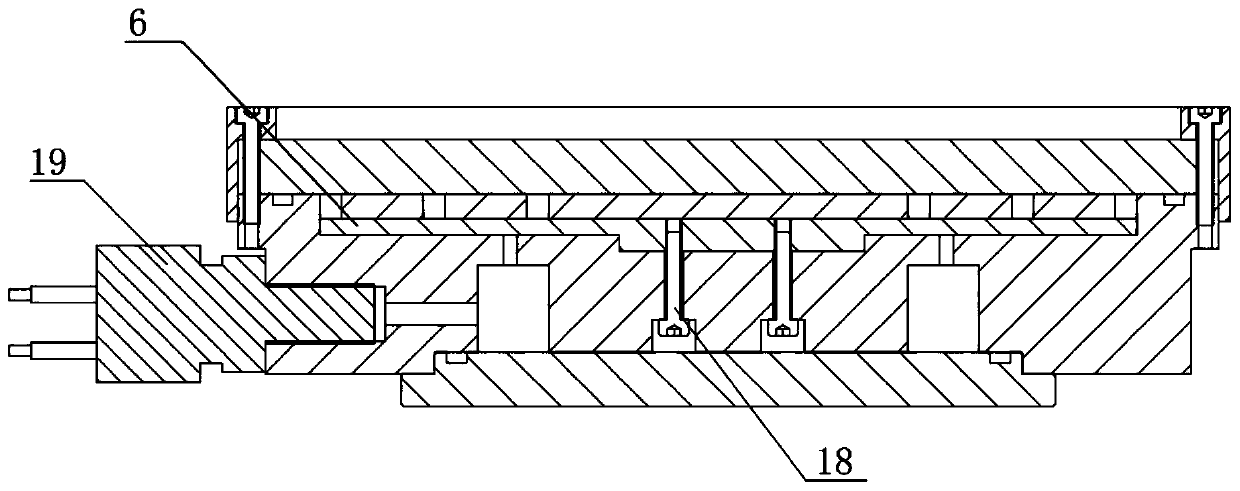

[0025] Such as figure 2 , image 3 and Figure 4 As shown, a pressure-resistant high-power LED lamp array includes a lamp body 2. The front and back sides of the lamp body 2 are respectively provided with cavities, and the metal is fixed in the cavity on the front of the lamp body 2 through fastening bolts 18. The heat sink 6, the metal heat sink 6 in this embodiment is a copper heat sink. On the surface of the metal heat sink 6 and along the center of the metal heat sink 6, aluminum alloy heat sinks are sequentially arranged from the inside to the outside. In this embodiment, the aluminum alloy heat sink The inner ring aluminum alloy heat dissipation plate 7, the middle ring aluminum alloy heat dissipation plate 9, and the outer ring aluminum alloy heat dissipation plate 11 are fixed on the surface of the copper heat dissipation plate by bolts. Ring grooves are formed between adjacent aluminum alloy h

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap