Method for monitoring fluctuation of MOSFET gate line end cutting process

A cutting process and gate line technology, applied in the field of monitoring the fluctuation of MOSFET gate line end cutting process, can solve the problem of not representing the uniformity of on-chip feature size, increasing measurement time and equipment investment, affecting authenticity and accuracy, etc. problems, to achieve the effect of improving product yield, avoiding measurement impact, and saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The method for monitoring the fluctuation of the MOSFET gate line end cutting process, in the following embodiments, taking a typical 28nm Poly-SiON (polysilicon gate-silicon oxynitride dielectric) MOSFET as an example, the specific implementation process is as follows:

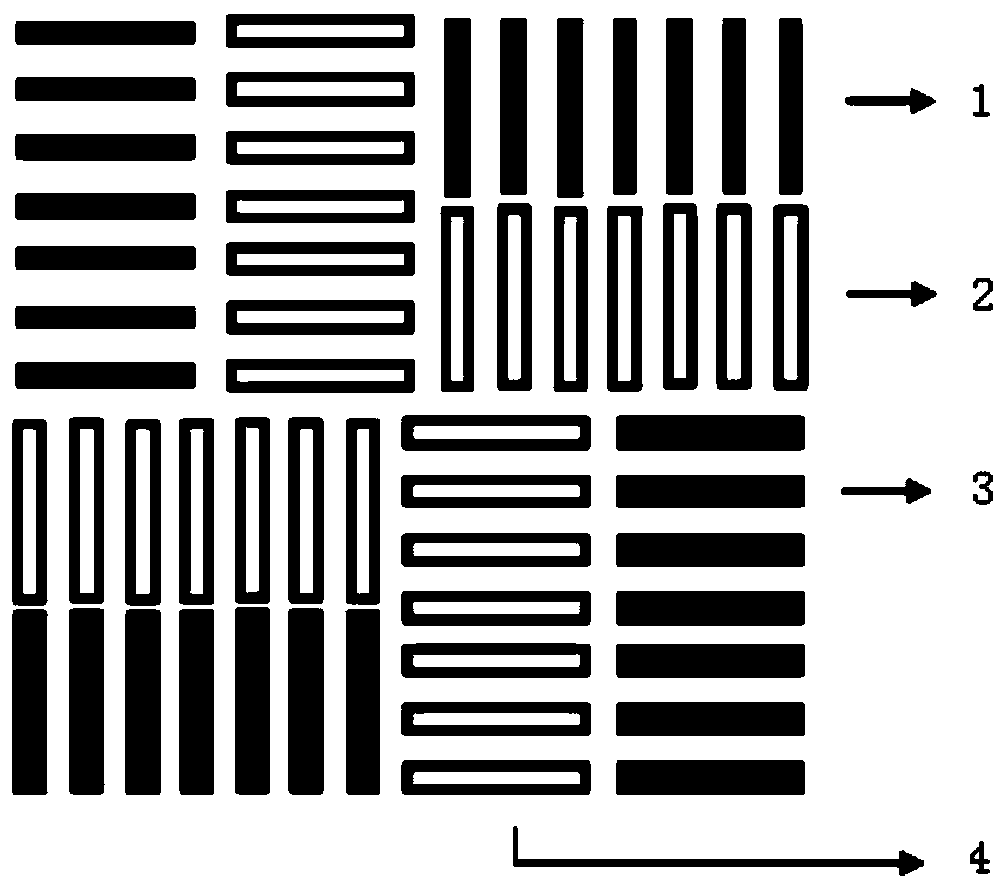

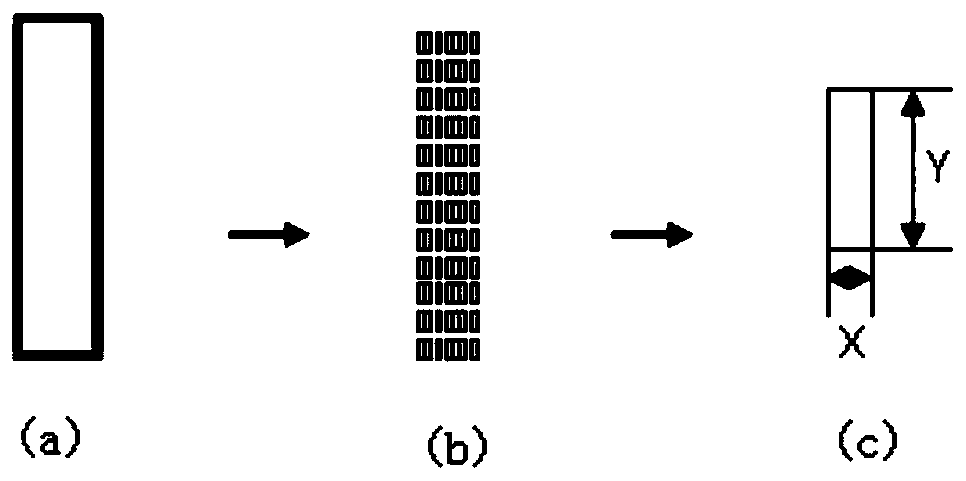

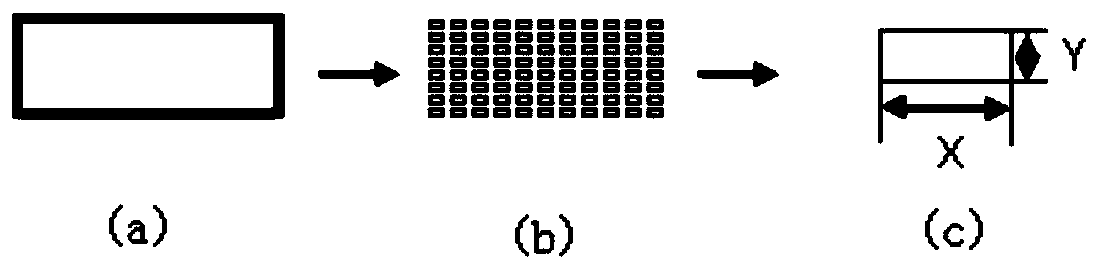

[0014] Step 1. Combine figure 1 As shown, the overlay pattern of the front layer grid is made, and the pattern is composed of a plurality of regularly arranged linear strips, and is arranged on the periphery of the entire overlay mark. The overlay pattern of the front grid is in the shape of a windmill. The gate overlay pattern on the front layer can also be composed of a plurality of grid bars, the length of the grid bars is 2-10 μm, the width is 0.5-2 μm, and the distance between the grid bars is 0.5-2 μm.

[0015] Step two, combine figure 1 As shown in the figure, the overlay pattern is made when the gate line end of the layer is cut. The pattern is composed of a plurality of regularly arranged long

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap