Switching power supply control system of multiple voltage levels

A multi-voltage level, switching power supply technology, applied in the electronic field, can solve the problems of inability to select, limited selection range of power devices, and inability to fully drive power tubes, etc., to achieve high driving voltage, widen the selection range, and economical chip area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

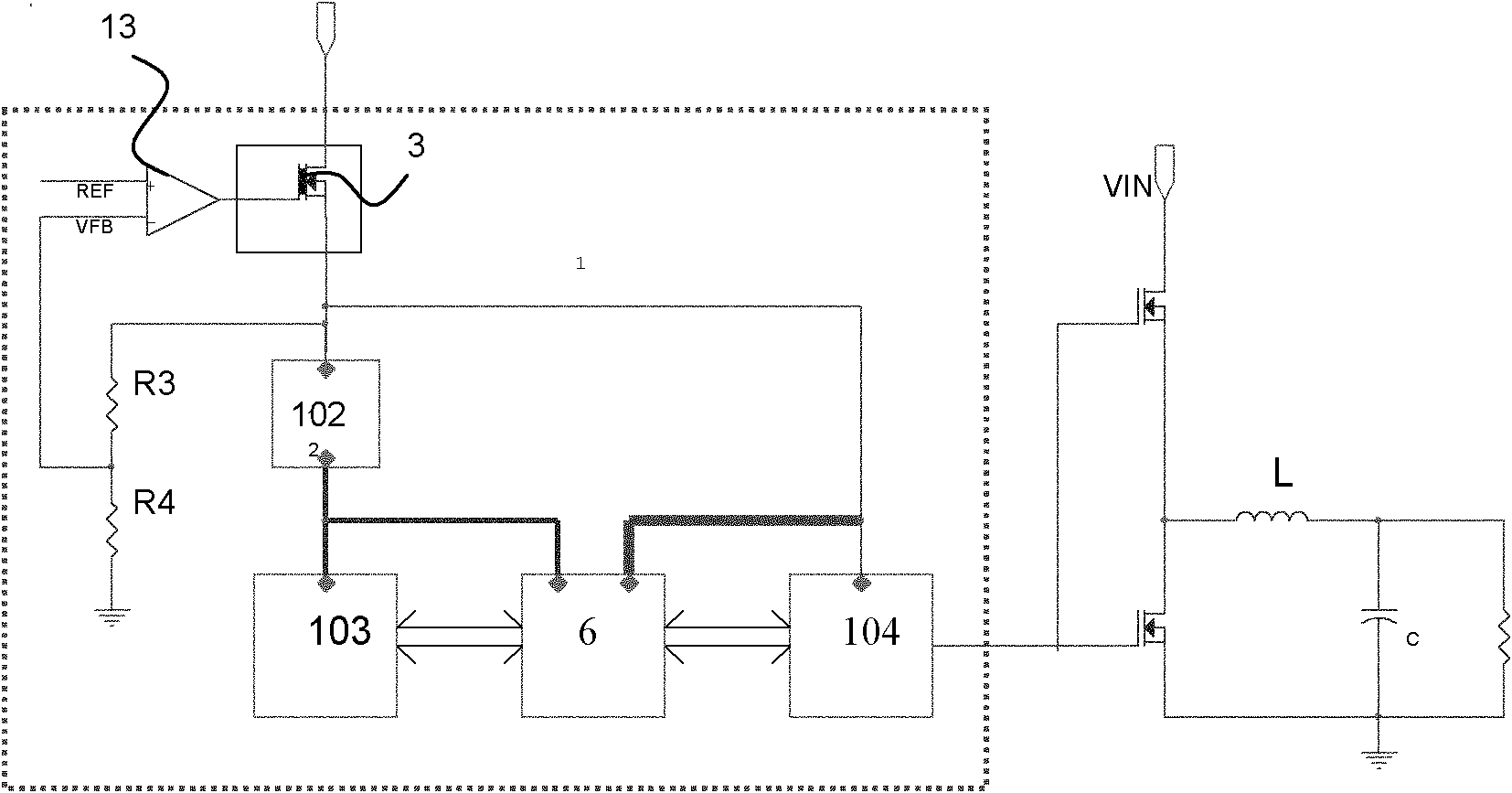

[0014] see Figures 2 to 4 .

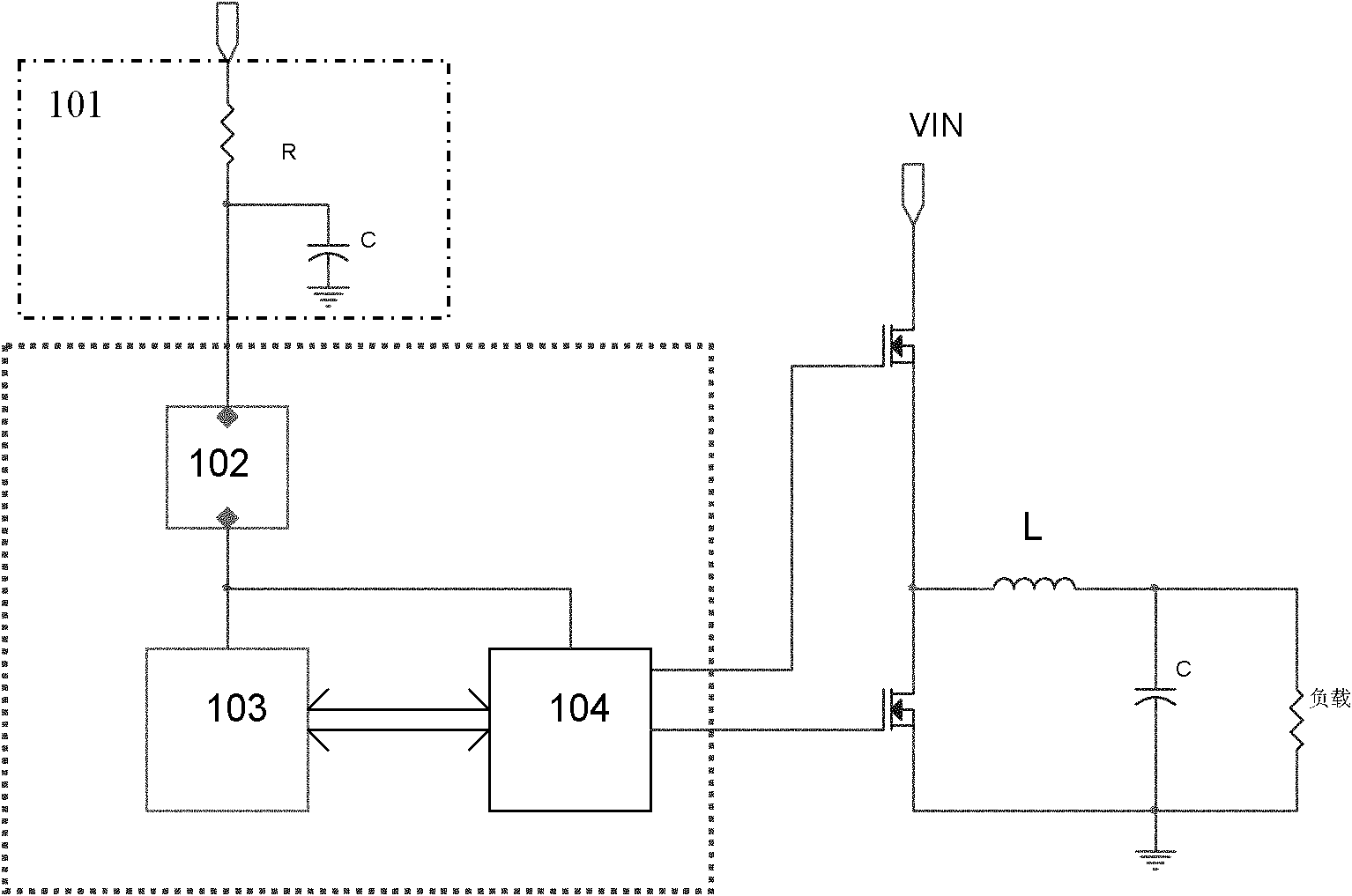

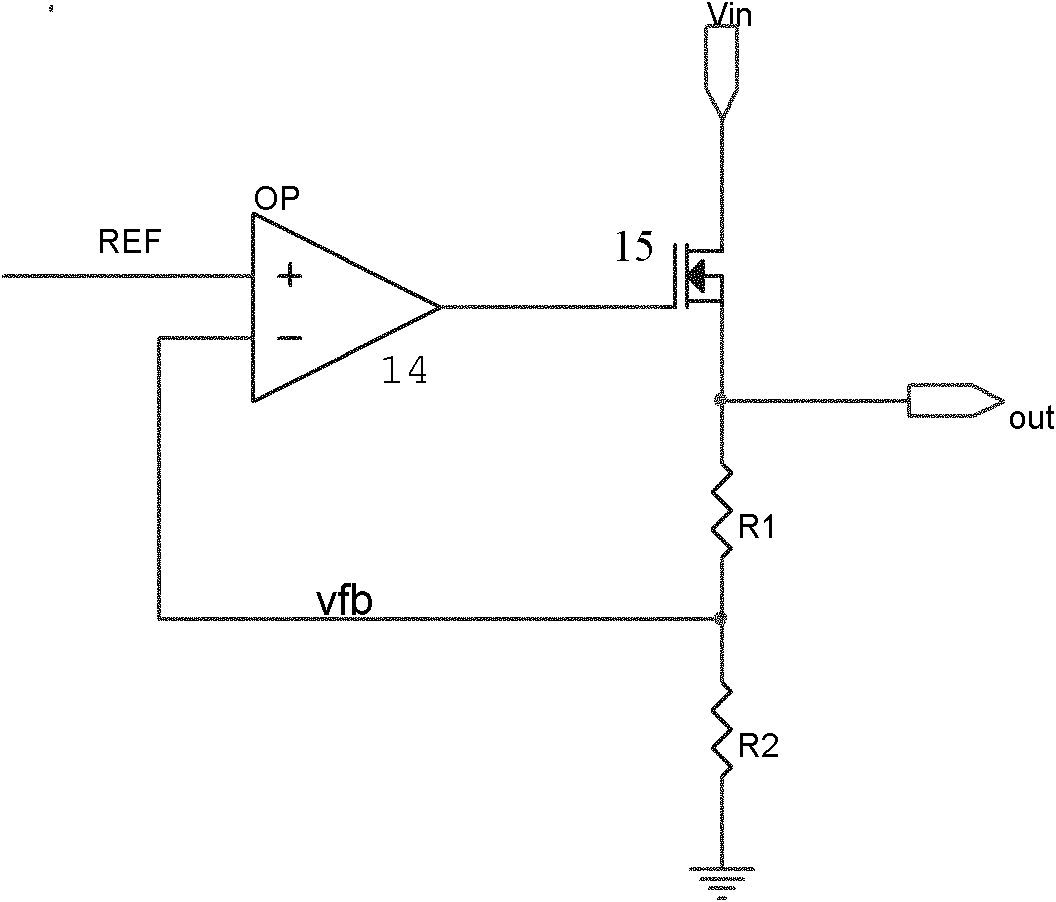

[0015] The present invention includes a first-stage voltage adjustment module 101, a second-stage voltage adjustment module 102, a low-voltage control module 103 and a high-voltage control module 104. The first-stage voltage adjustment module 101 includes a depletion MOSFET device 3, an operational amplifier 13, The feedback loop formed by the third resistor R3 and the fourth resistor R4, the output terminal of the operational amplifier 13 is connected to the gate of the depletion MOSFET device 3, the drain of the depletion MOSFET device 3 is the high voltage input terminal, and the source is the first stage The output terminal of the voltage adjustment module 101 is connected to the second-stage voltage adjustment module 102, and the source of the depletion MOSFET device 3 is also connected to the negative input terminal of the operational amplifier 13 through the third resistor R3, and the negative input terminal of the operational amplifier 13 G

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap