Resin material supply mechanism and resin material supply method

A resin material and resin sealing technology, applied in the field of resin material supply mechanism, can solve the problem of poor efficiency of resin material transportation, and achieve the effect of excellent efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] Hereinafter, an aspect for implementing the present invention (hereinafter, referred to as an "embodiment") will be described with reference to the drawings.

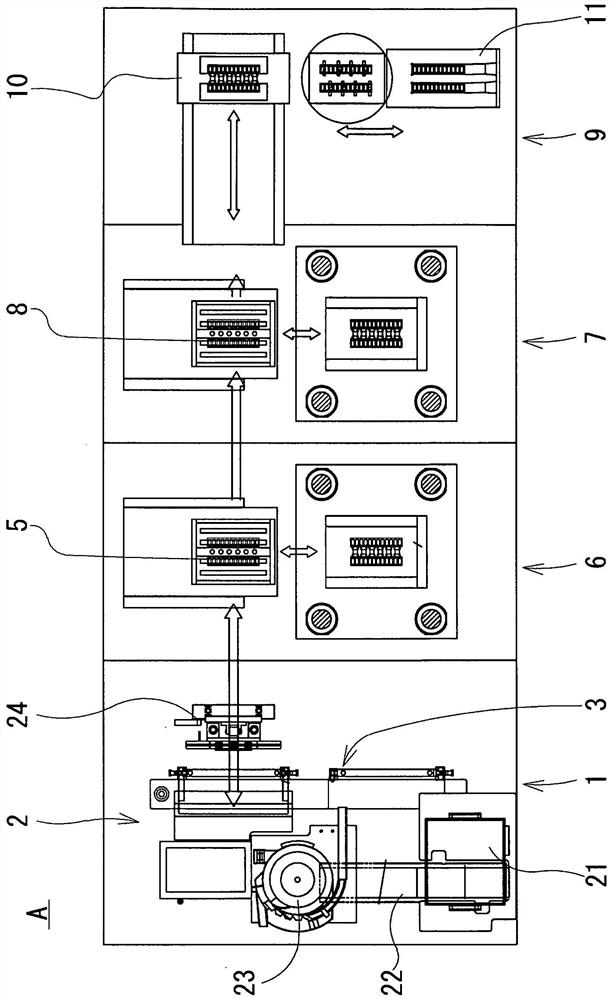

[0088] In addition, in this embodiment, the figure 1 As a reference, the position of the press unit 6 relative to the material supply unit 1 is set to "right" or "right", and the position of the material supply unit 1 relative to the press unit 6 is set to "left" or "left". In addition, with figure 1 As a reference, the position of the drum feeder 23 relative to the hopper 21 is referred to as "front" or "front", and the position of the hopper 21 relative to the drum feeder 23 is referred to as "rear" or "rear". In addition, the figure 1 The front-rear direction and the left-right direction as a reference are the moving directions of the sheet conveying block 32 .

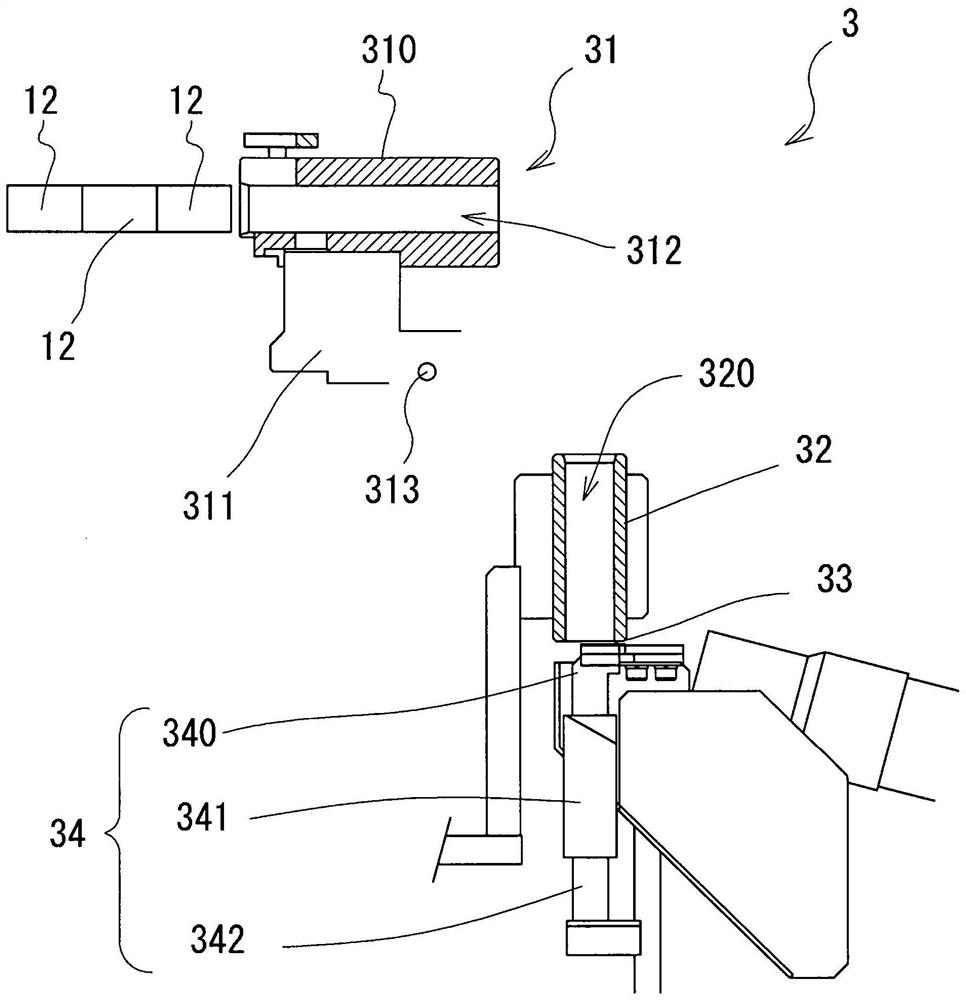

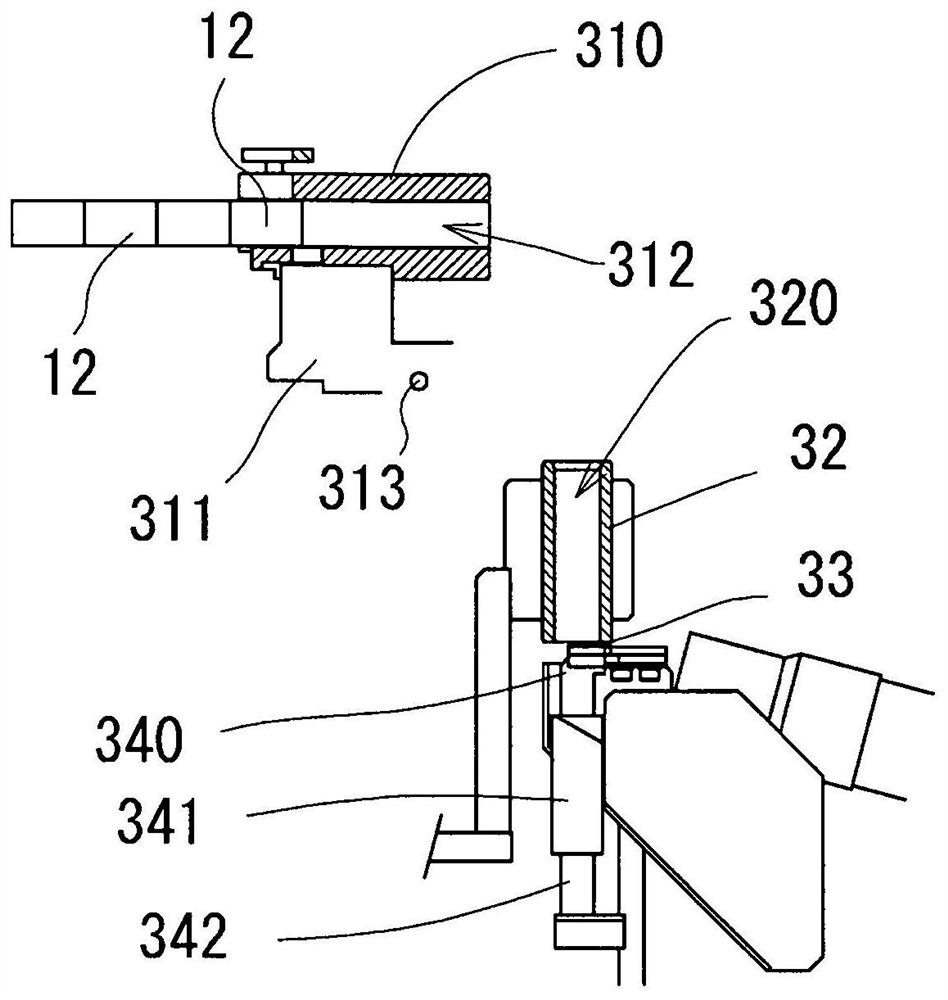

[0089] In addition, in this embodiment, the Figure 4 As a reference, the position of the measuring element 340 relative to the stopper 33 is set to

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap