Virtual debugging system for intelligent manufacture

A technology for intelligent manufacturing and debugging systems, applied in control/regulation systems, general control systems, program control in sequence/logic controllers, etc., can solve problems that cannot guarantee the correctness and stability of data transmission, and do not design good interactive performance PC client, no feedback from simulation software, etc., to achieve the effect of improving function scalability, speed and correctness, and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

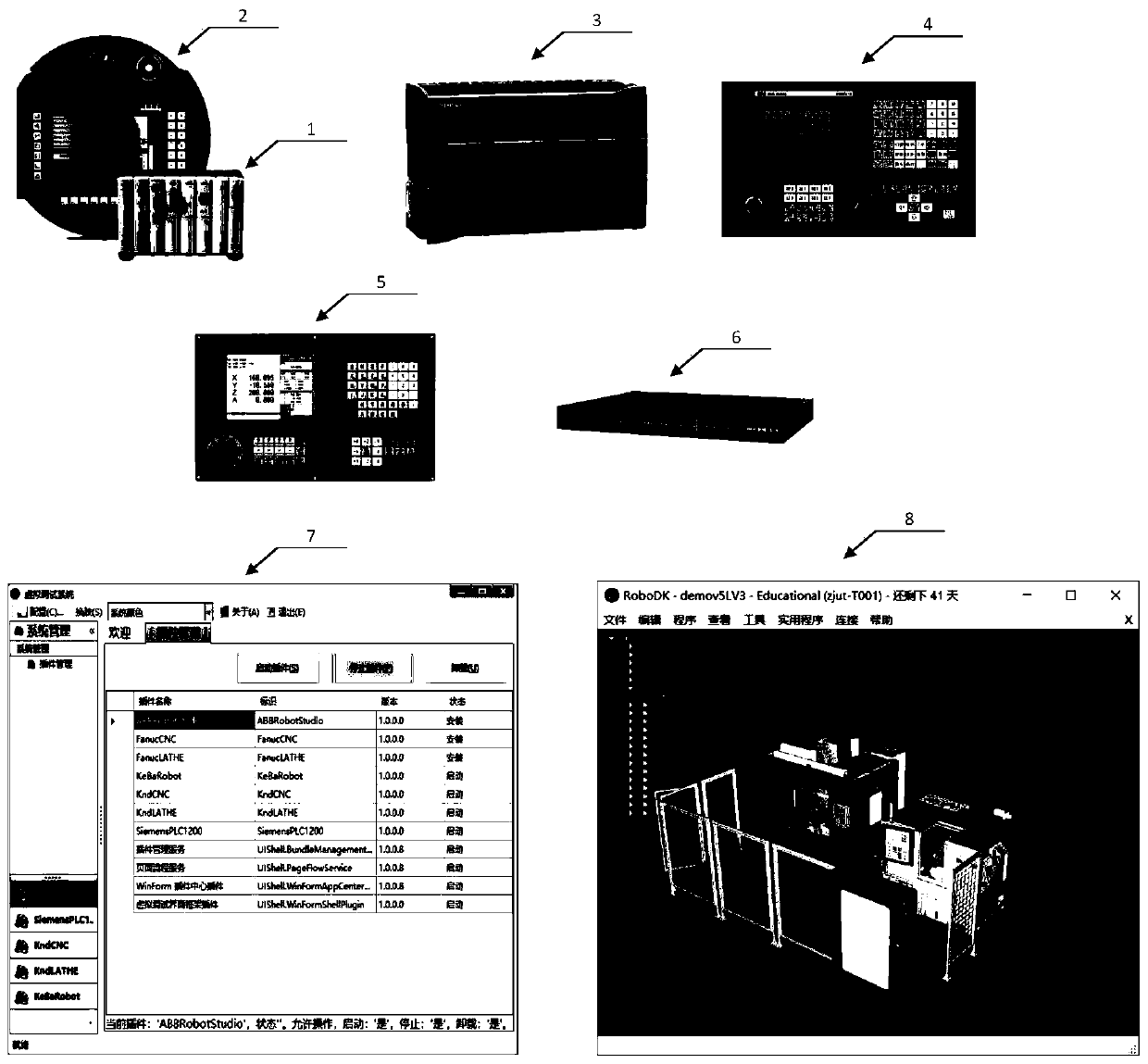

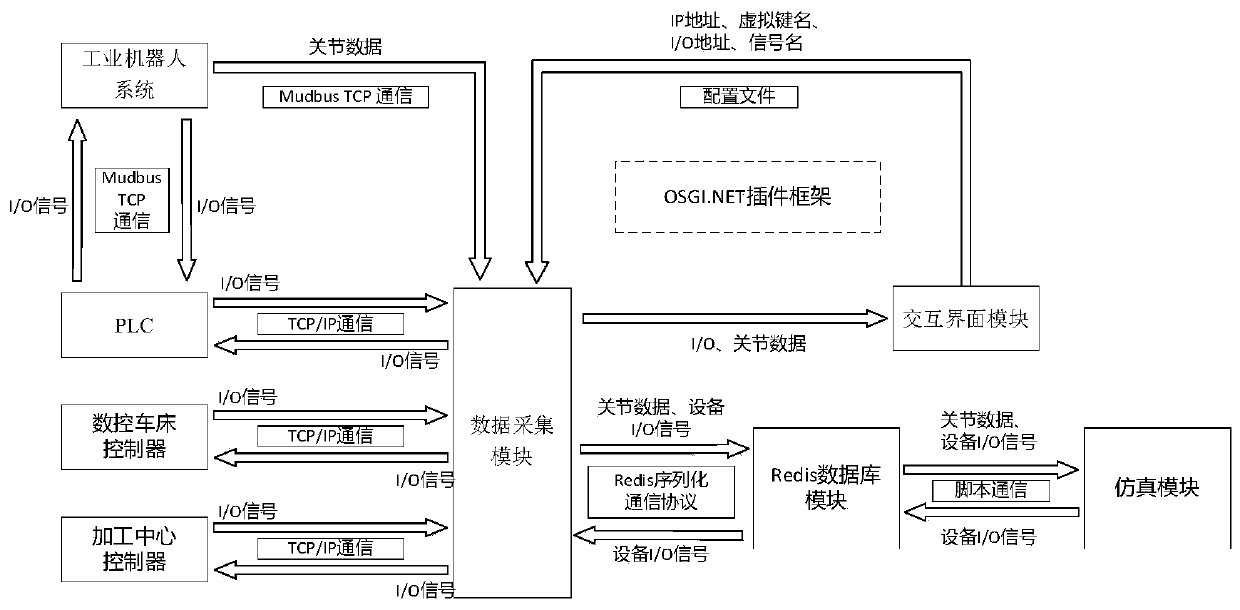

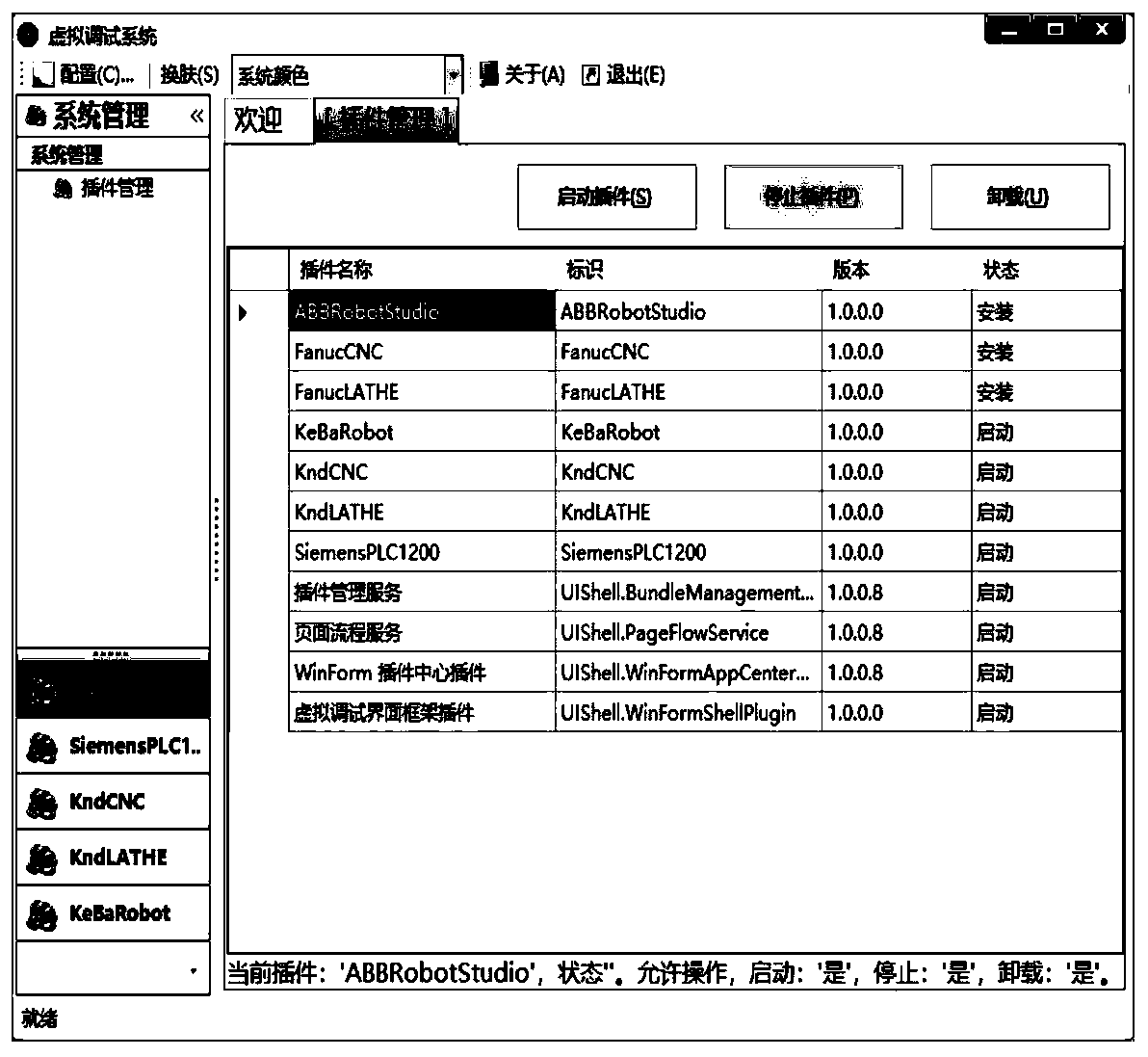

[0027] combine figure 2 And Fig. 3, the specific implementation mode of the patent of the present invention is as follows:

[0028] The PC client, Redis database and simulation software are installed on the computer, and then the control equipment is wired and powered, and connected to the computer through the industrial Ethernet to perform virtual debugging.

[0029] The industrial robot system adopts KEBA industrial robot, including KEBA robot controller and teaching box, and uses the teaching box to select and start the robot program. The robot controller communicates with PLC through Mudbus TCP, and transmits I / O signals to PLC After the feedback is completed, the joint data is also sent to the data acquisition module of the PC client. The robot program mainly completes the tasks of picking the workpiece out of the warehouse, putting and picking up the part to the CNC lathe, putting and picking up the part to the machining center, and putting the finished product into the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap