Setting machine exhaust gas processing equipment energy consumption automatic adjusting system

A waste gas treatment equipment and automatic adjustment technology, applied in control/regulation systems, non-electric variable control, instruments, etc., can solve problems such as energy consumption and inability to ensure rational utilization of resources, and achieve the effect of ensuring rational utilization and guaranteeing resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

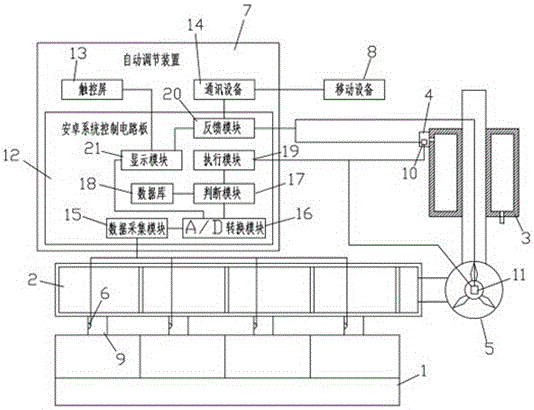

[0015] Such as figure 1 As shown, an automatic adjustment system for energy consumption of waste gas treatment equipment of a setting machine, including a setting machine 1, a flue 2, a water tank 3, a water pump 4, a fan 5, a thermocouple sensor 6, an automatic adjustment device 7 and a mobile device 8; The flue 2 is "L"-shaped, and the flue 2 is installed on the top of the smoke outlet 9 of the setting machine 1, and the thermocouple sensor 6 is fixed on the inner wall of the smoke outlet 9; the fan 5 is fixed on the flue 2 At the inflection point, the water tank 3 is fixed on the outer wall of one end of the flue 2, the water pump 4 is fixed on the water tank 3, and the frequency converter a10 is installed on the water pump 4, and the frequency co

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap