Vehicle-mounted high beam system

A technology of high beam and power supply system, applied in the field of high beam system, can solve the problems of instability of vehicle high beam system, cannot be controlled by infrared light, easy to fail, etc., to achieve stability of vehicle high beam system, realize uninterrupted power supply, The effect of being less prone to failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

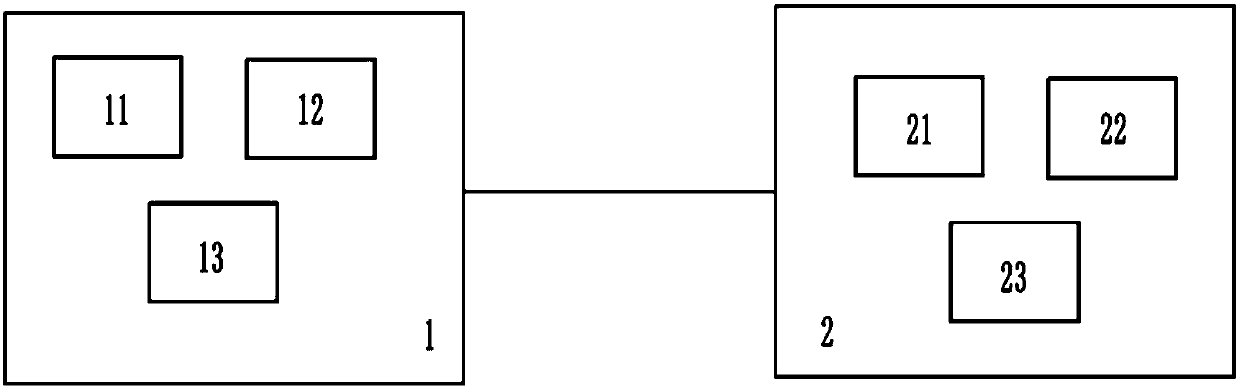

[0029] like figure 1 As shown, a vehicle-mounted high beam system provided by the present invention includes a power supply system 1 and a lighting device 2. The power supply system 1 and the lighting device 2 are electrically connected through a connecting device. The power supply system 1 includes a power generation system 11, a frequency converter 12 and The bus bar 13, the lighting device 2 includes a high-beam lamp 21, a support 22 for installing the high-beam lamp 21 and a control system 23, the power generation system 11 is electrically connected to the frequency converter 12 through a first electric wire, so as to supply power to the frequency converter 12, The frequency converter 12 is connected to the bus bar 13 through the second electric wire, the bus bar 13 is connected to the lighting device 2 through the connecting device, the high beam lamp 21 is detachably installed on the support 22, and the control system 23 is set as infrared light control to control The light

Embodiment 2

[0032] like figure 1 As shown, a vehicle-mounted high beam system provided by the present invention includes a power supply system 1 and a lighting device 2. The power supply system 1 and the lighting device 2 are electrically connected through a connecting device. The power supply system 1 includes a power generation system 11, a frequency converter 12 and The bus bar 13, the lighting device 2 includes a high-beam lamp 21, a support 22 for installing the high-beam lamp 21 and a control system 23, the power generation system 11 is electrically connected to the frequency converter 12 through a first electric wire, so as to supply power to the frequency converter 12, The frequency converter 12 is connected to the bus bar 13 through the second electric wire, the bus bar 13 is connected to the lighting device 2 through the connecting device, the high beam lamp 21 is detachably installed on the support 22, and the control system 23 is set as infrared light control to control The light

Embodiment 3

[0035] like figure 1 As shown, a vehicle-mounted high beam system provided by the present invention includes a power supply system 1 and a lighting device 2. The power supply system 1 and the lighting device 2 are electrically connected through a connecting device. The power supply system 1 includes a power generation system 11, a frequency converter 12 and The bus bar 13, the lighting device 2 includes a high-beam lamp 21, a support 22 for installing the high-beam lamp 21 and a control system 23, the power generation system 11 is electrically connected to the frequency converter 12 through a first electric wire, so as to supply power to the frequency converter 12, The frequency converter 12 is connected to the bus bar 13 through the second electric wire, the bus bar 13 is connected to the lighting device 2 through the connecting device, the high beam lamp 21 is detachably installed on the support 22, and the control system 23 is set as infrared light control to control The light

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap