Electromagnetic heating controller

A heating controller and electromagnetic technology, applied in the direction of induction heating control, induction heating, etc., can solve the problems of low electrothermal conversion efficiency, low power density, poor stability, etc., achieve improved stability, high degree of automation, and maintain stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

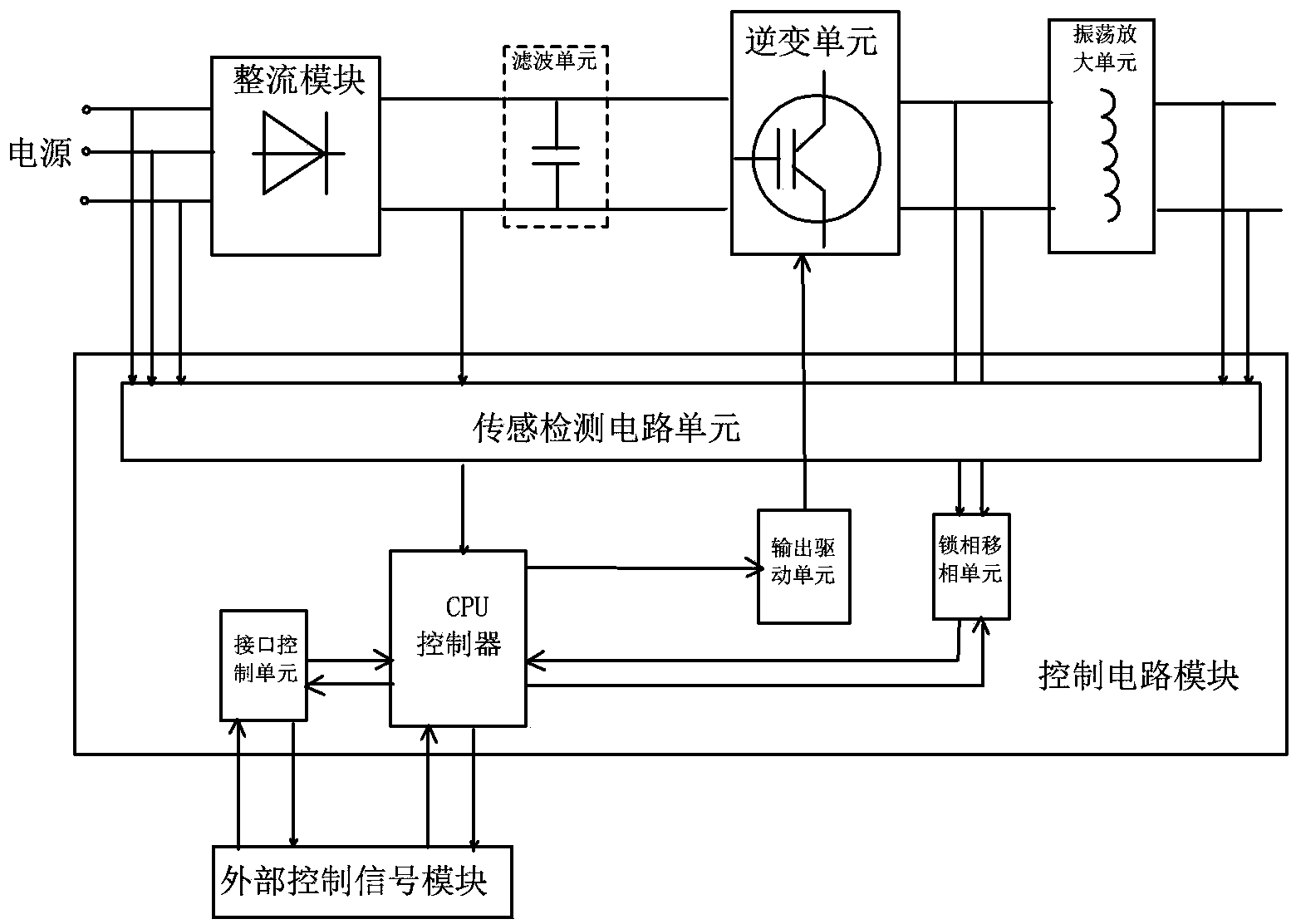

[0012] The high-efficiency electromagnetic heating tube of the present invention draws on the "AC-DC-AC" hardware structure of the current mature frequency converter system, and configures a dedicated control circuit to form this controller system, as shown in the attached figure 1 As shown, it includes a rectifier module, a filter unit, an inverter unit, and an oscillation amplification unit. The oscillation amplification unit includes an inductance coil and an oscillation controller electrically connected to it, and a resistor can also be added. The filter unit is a capacitor or a capacitor group.

[0013] The rectification module is electrically connected to the filter unit, the filter unit is electrically connected to the inverter unit, and the inverter unit is electrically connected to the oscillation amplification unit.

[0014] It also includes a control circuit module, the control circuit module includes a sensing detection circuit unit, a CPU controller, an output drive u

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap