Filling method and filling equipment for fruit juice

A technology of filling equipment and fruit juice, which is applied in packaging, bottling machines, synchronous devices, etc., can solve the problems of easy to fall into impurities, difficult to completely remove liquid, etc., and achieve the effect of ensuring stability, compact structure, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] The invention will be further described below in conjunction with the embodiments in the accompanying drawings.

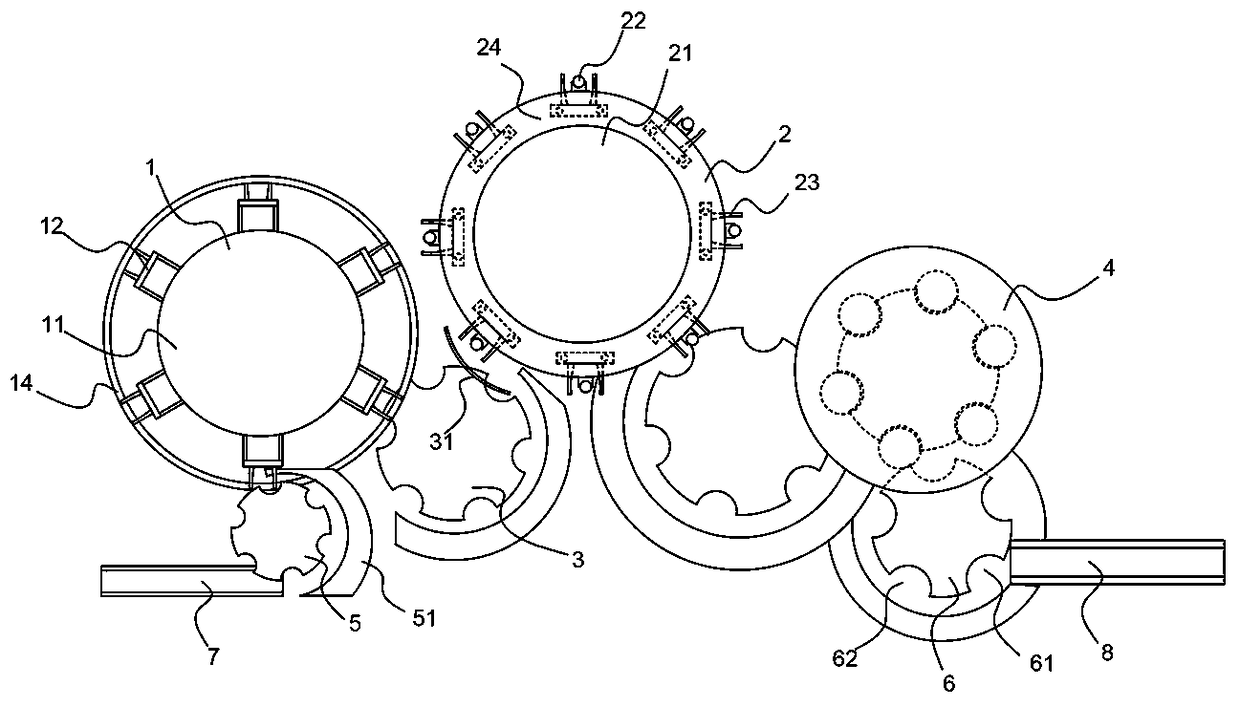

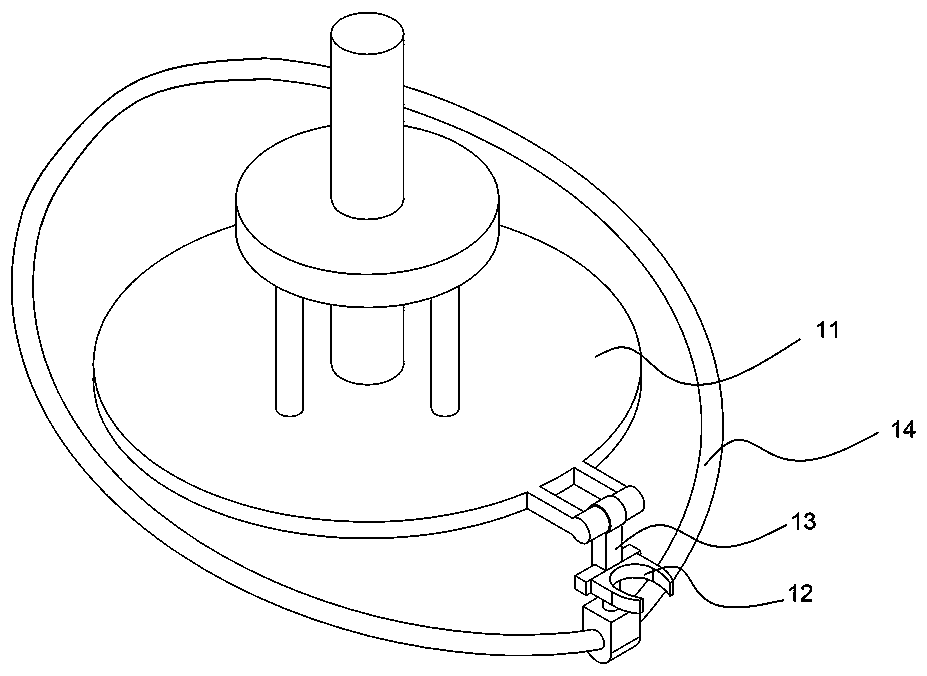

[0022] like figure 1 and figure 2 The shown juice filling equipment includes a bottle washing machine 1 and a filling machine 2. The bottle washing machine 1 includes a rotatable bottle washing turntable 11, and the bottle washing turntable 11 is driven to rotate by a motor at its lower end. A first holding clip 12 is hingedly arranged along the circumference of the bottle washing turntable 11, a connecting rod 13 is hinged on the first holding clip 12, a guide rod 14 is provided on the side of the bottle washing turntable 11, and one end of the connecting rod 13 is sleeved on the guide rod 14. On the upper side, the guide rod 14 is partially located on the lower side of the first holding clip 12 and partially on the upper side of the first holding clip 12 along the circumferential direction of the bottle washing turntable 11 . The guide rod 14 surrounds the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap