Isolated gas lift drainage method

A gas-lift drainage and isolation technology, which is used in earth-moving drilling, sealing/packing, and fluid production. It can solve the problems of multiple downholes, complex processes, distance errors, etc., and achieve precise installation position control and simple process steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

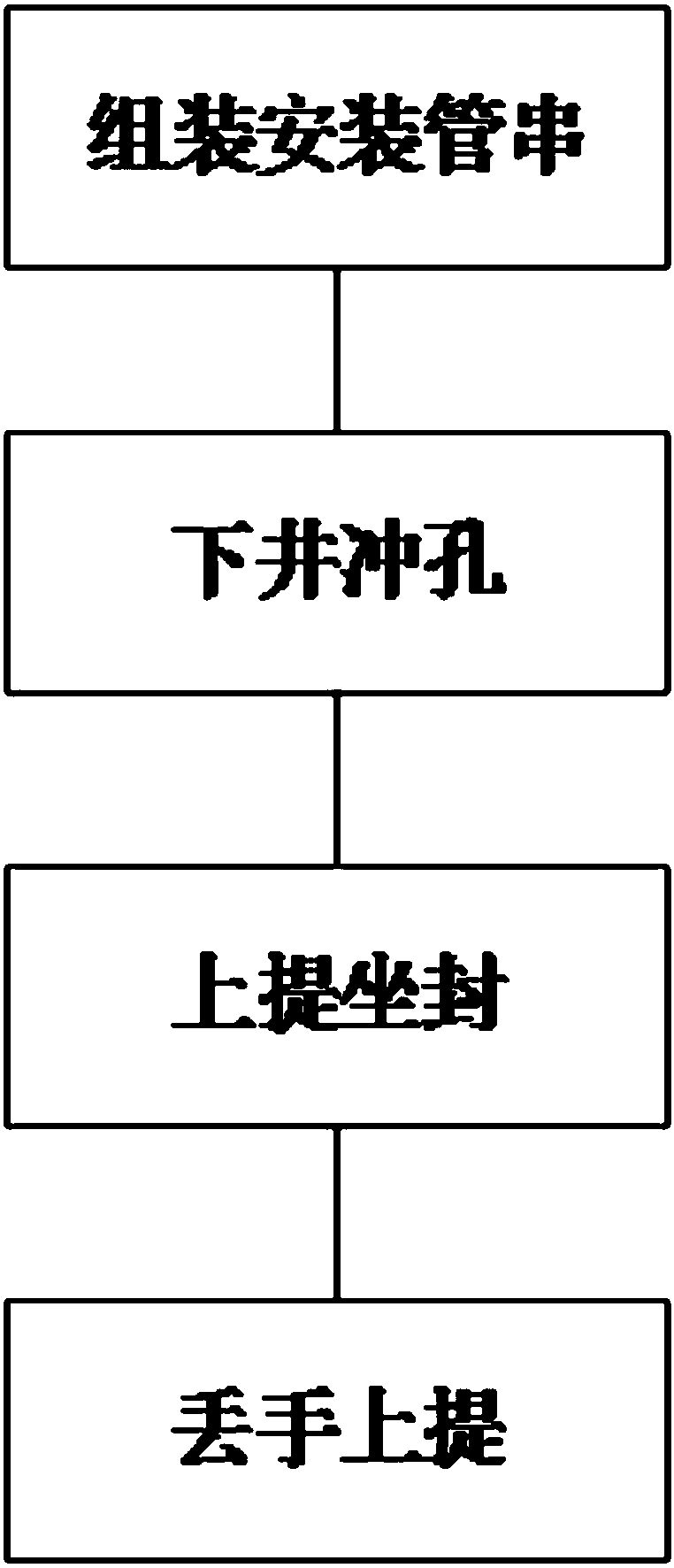

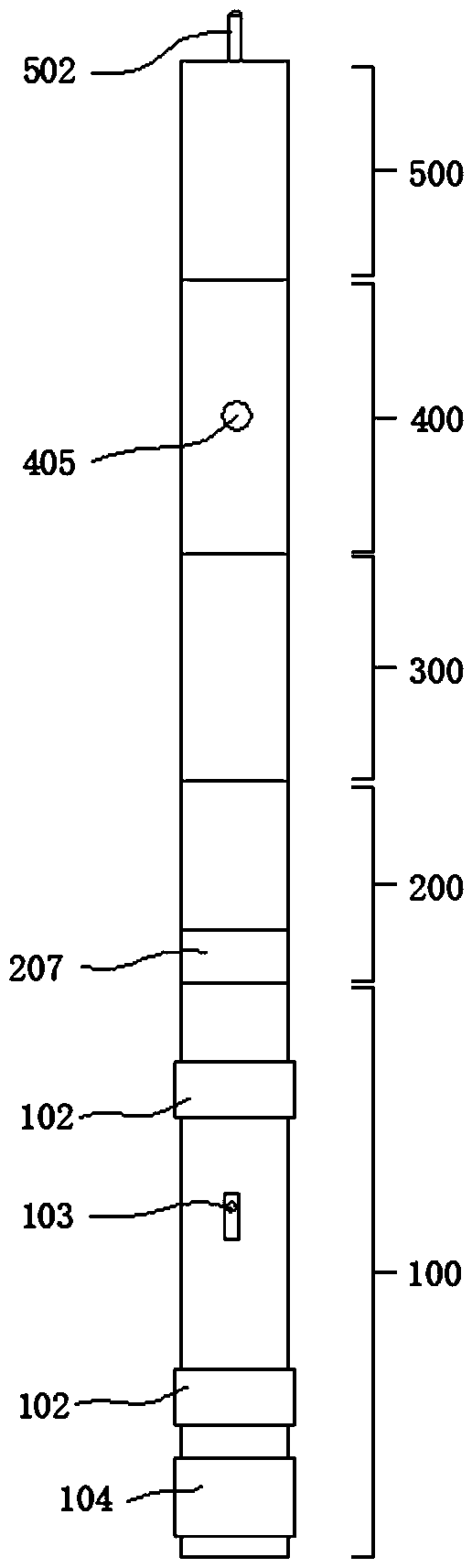

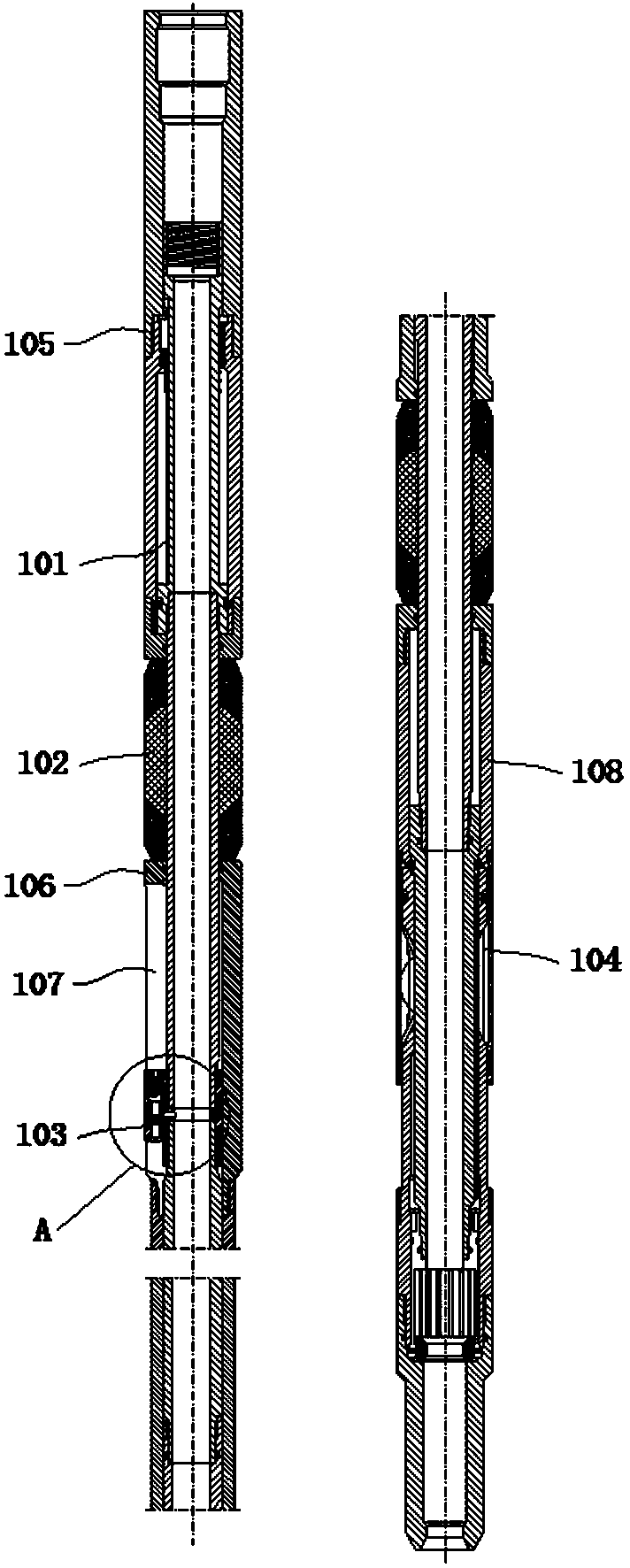

[0045] like figure 1 and figure 2 As shown, in an isolated gas lift drainage method of the present invention, the isolated gas lift drainage gas production pipe string is used to remove the liquid accumulation in the well, reduce the pressure of the liquid accumulation, and restore the production of the gas well. The isolated gas lift drainage gas production pipe string includes Isolated gas lift packer, setting tool, activation device and punching gun, including the following steps:

[0046] S1. Assembling and installing the pipe string; first, connect the first starting device, the punching gun 400, the second starting device and the isolated gas lift packer 100 in sequence, and the second starting device and the isolated gas lift packer 100 are connected by throwing Hand s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap