Embedded laundry unit

A laundry machine and embedded technology, applied in the field of household products, can solve the problems of poor integrity, bulkiness, and unsightly appearance, and achieve the effect of strong integrity, simple structure, flat and concise structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make those skilled in the art more clearly understand the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

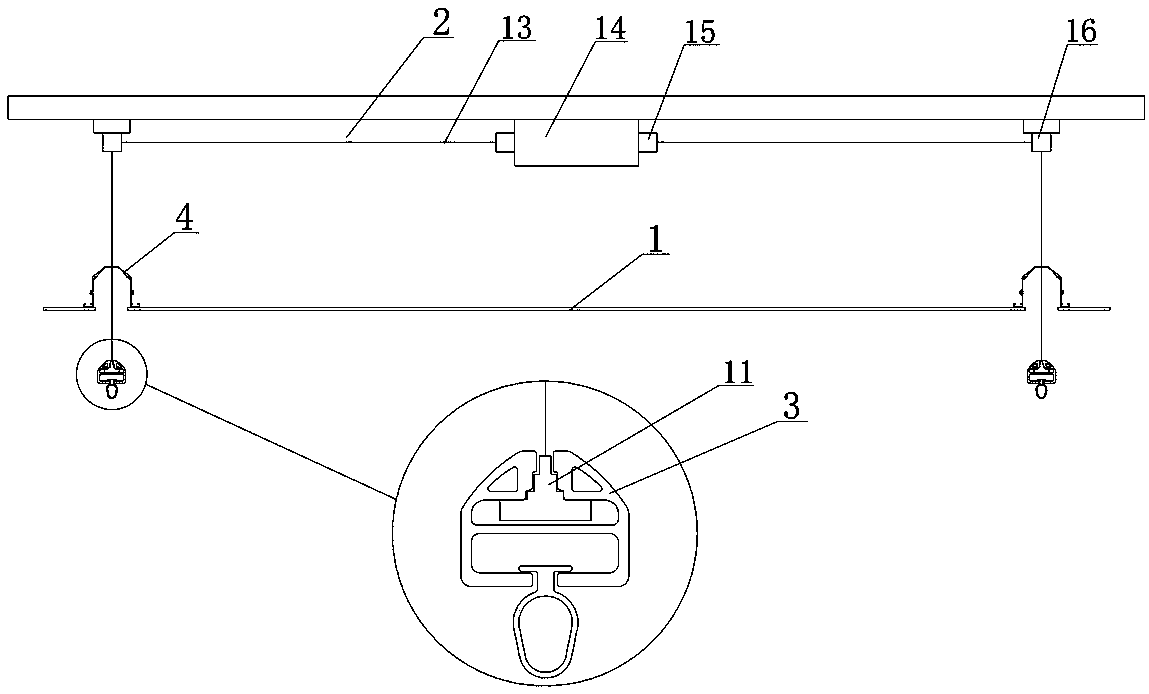

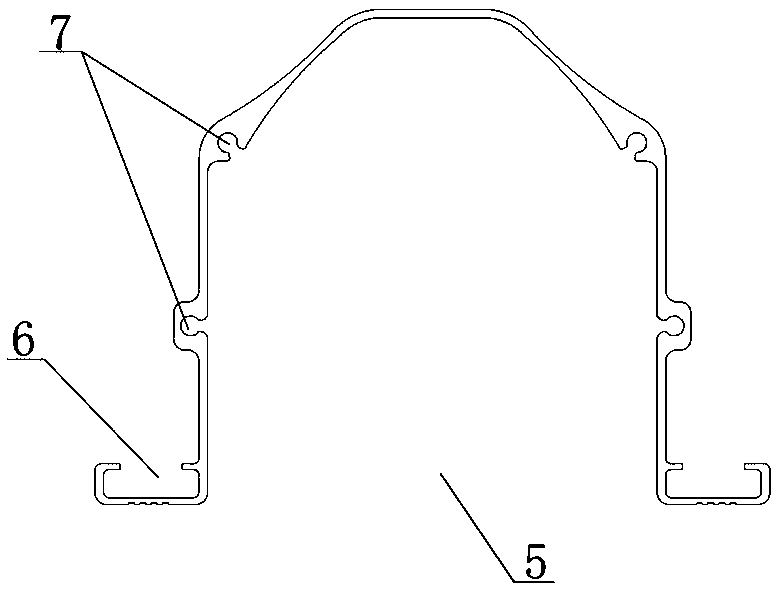

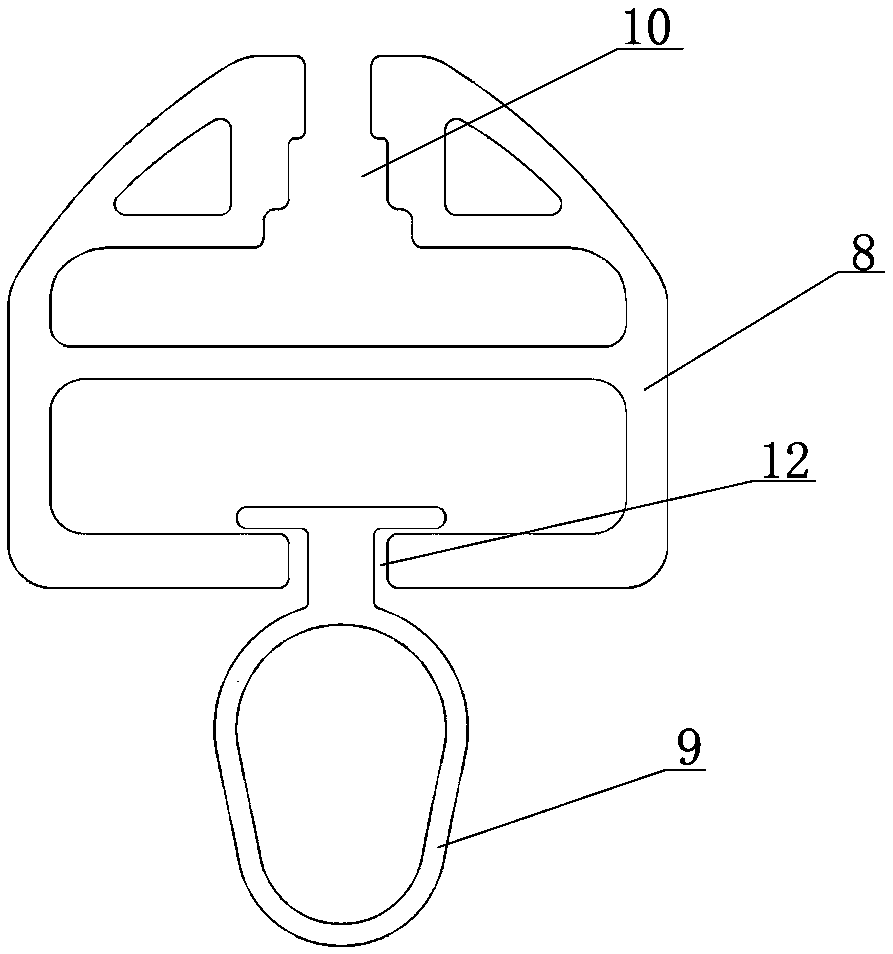

[0019] Such as Figure 1-3 As shown, an embedded clothes dryer according to the present invention includes a ceiling panel 1 and a clothes dryer body embedded in the ceiling panel 1, and the clothes dryer body includes a lifting device 2, a number of clothes rails 3 and The number of installation racks 4 is the same as that of the clothes-horse 3, and the clothes-horse 3 is connected below the installation rack 4 through a lifting device 2, and the lifting device 2 is used to drive the up or down of the clothes-horse 3 ; The mounting frame 4 is a strip-shaped structure with an opening at the bottom, the mounting frame 4 is provided with a concave cavity body 5 for accommodating the clothes-horse 3, and the bottom sides

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap