Split-flow fluid director applied to underground water sampling and capable of accurately adjusting flow velocity

A shunt and groundwater technology, applied in the field of sampling pipes, can solve the problems of difficulty in meeting work needs, inability to accurately control the flow rate, etc., and achieve the effect of changing the outflow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

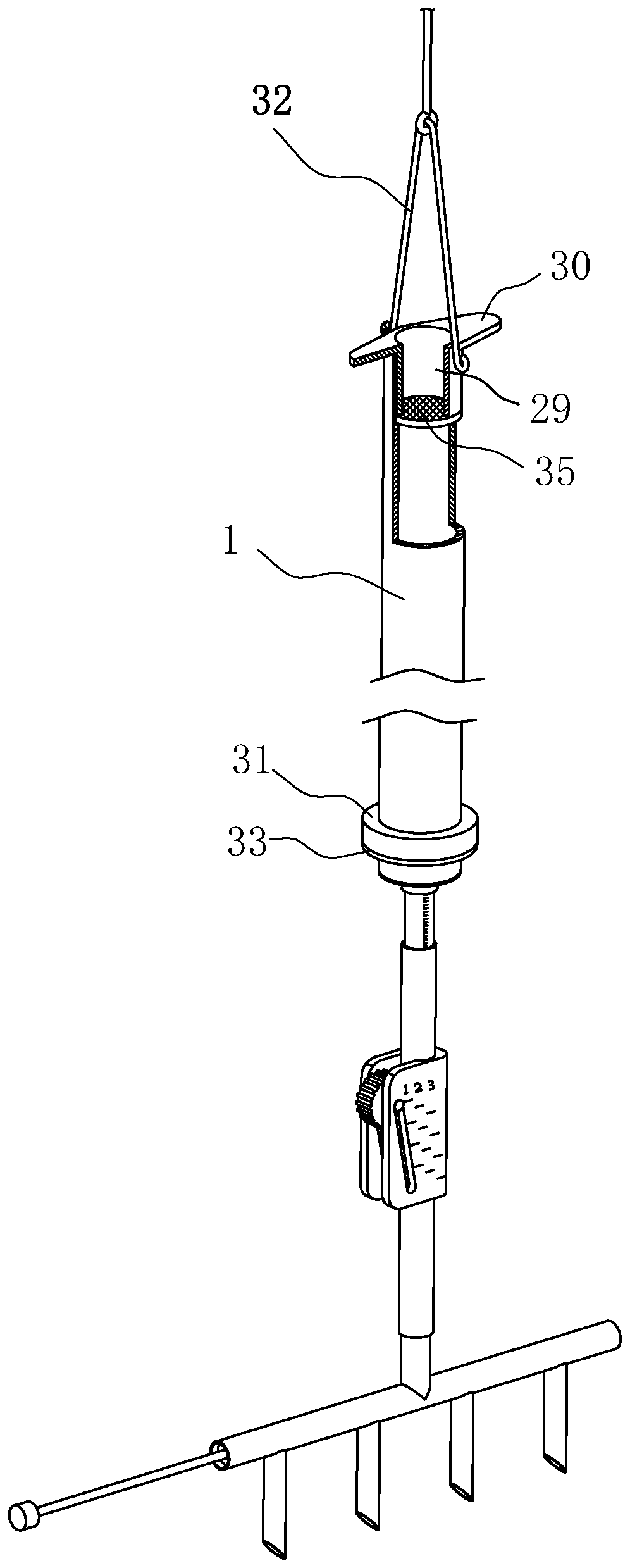

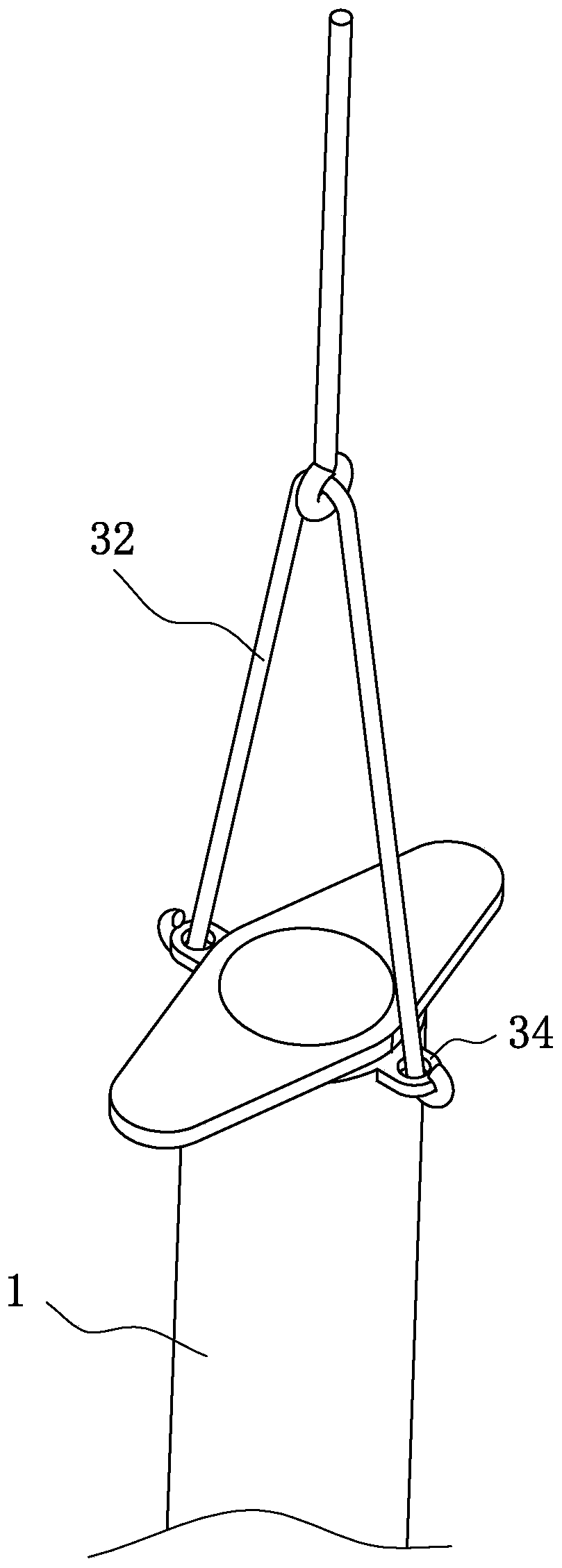

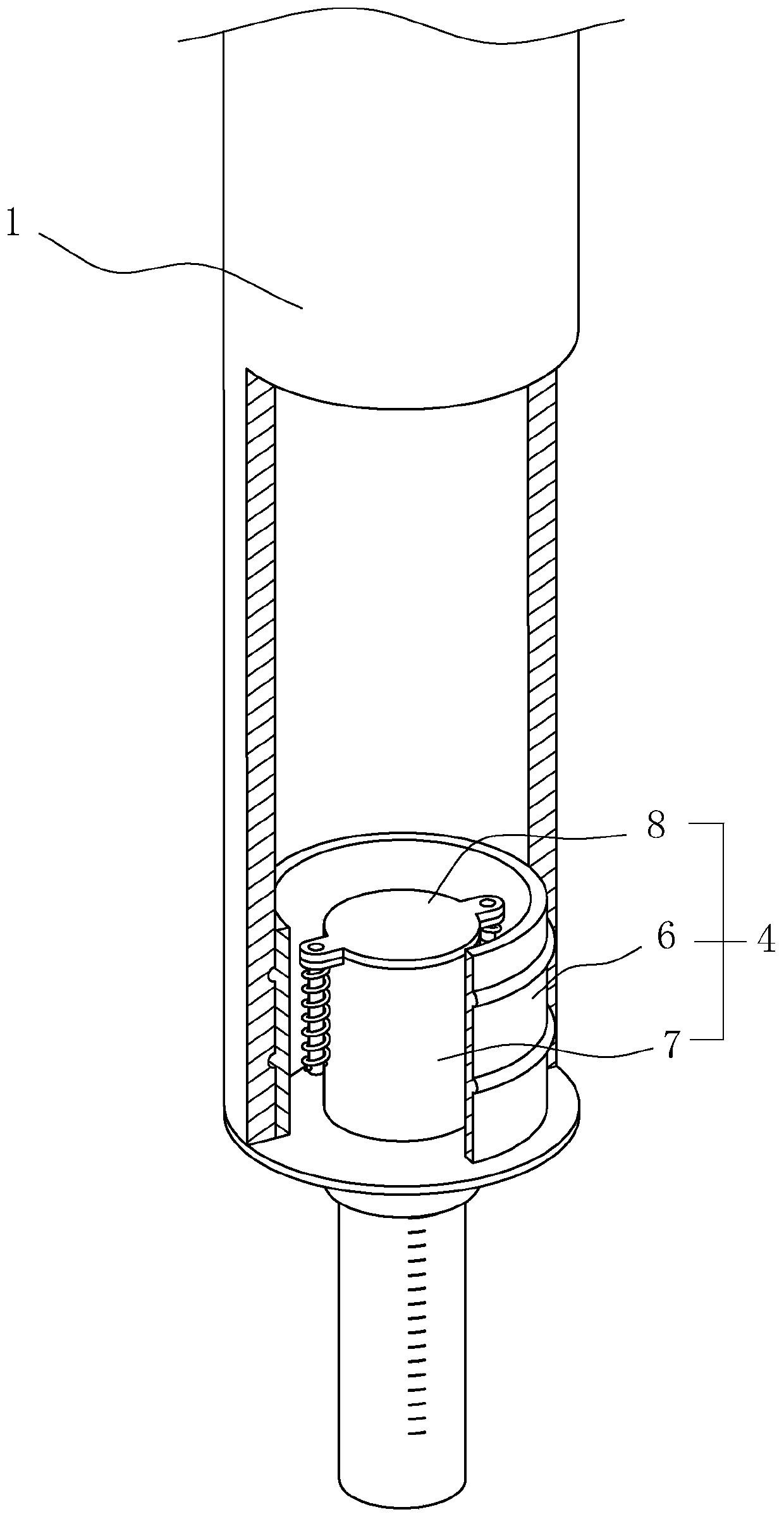

[0045] refer to figure 1 and figure 2 , which is a shunt-type deflector that can accurately adjust the flow rate for groundwater sampling disclosed in the present invention, including a pipe body 1, a sampling port and a sample outlet, and the sampling port and the sample outlet are respectively arranged at both ends of the pipe body 1 , the sampling port is set at the upper end of the tube body 1, and the sample outlet is set at the lower end of the tube body 1; the tube body 1 is made of transparent plastic material, and the upper end of the tube body 1 is integrally formed with two connecting rings 34, It is arranged symmetrically on both sides of the pipe body 1 , and two connecting rings 34 are bound with connecting ropes 32 . The outer wall of the pipe body 1 near the lower end is coated with a counterweight 31, and the outer wall of the pipe body 1 is provided with a support ring 33 for supporting the counterweight 31. The support ring 33 is integrally formed with the pi

Embodiment 2

[0059] refer to Figure 6 and Figure 5 The difference between the present invention and the embodiment 1 is that a split flow deflector that can accurately adjust the flow rate for groundwater sampling is: the end of the sample outlet pipe 7 away from the drainage pipe 11 is provided with a guide cone 39, and the guide cone 39 is away from the drain pipe 11. One end of the sample pipe 7 is welded with an anti-drop rod 41, and the anti-drop rod 41 is arranged along the radial direction of the sample pipe 7; an opening and closing valve ball 40 is placed in the guide cone 39, and the anti-falling rod 41 can prevent the opening and closing valve from opening and closing. The ball 40 falls out from the guide cone 39 ; a filter screen 52 is arranged in the drainage tube 11 . One end of the drainage tube 11 extending into the sample outlet tube 7 is welded with an abutment rod 42, and the abutment rod 42 is arranged along the radial direction of the drainage tube 11. When the drainag

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap