Simulated installation method for three-cylinder crankshaft bearing of diaphragm pump

A technology for simulating installation and crankshaft bearings. It is applied in geometric CAD, computer-aided design, design optimization/simulation, etc. It can solve the problems of bearing and crankshaft installation stuck, unable to install, etc., to avoid stuck or unable to install.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

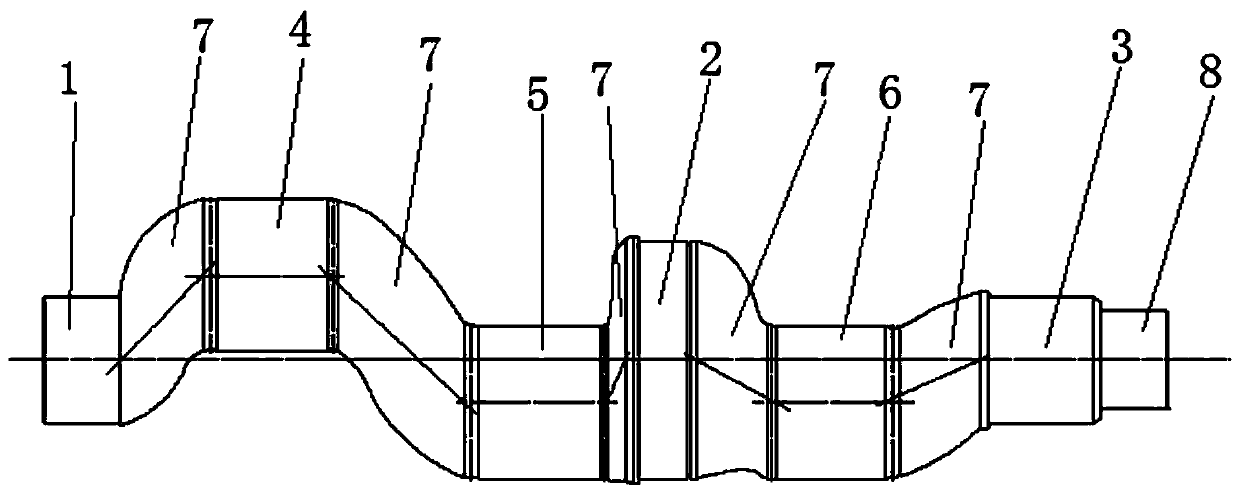

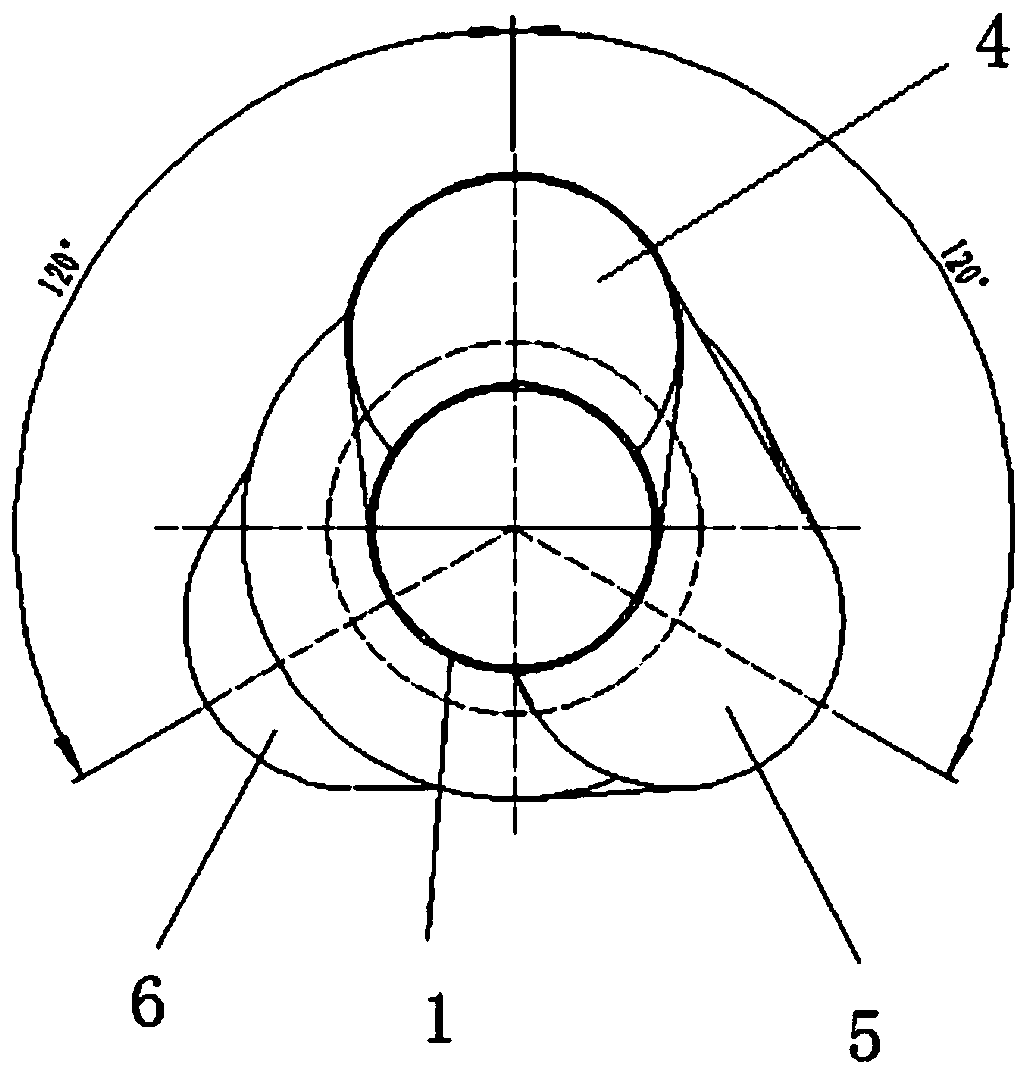

[0072] Such as Figure 1 to Figure 16 As shown, a simulated installation method of a three-cylinder crankshaft bearing of a diaphragm pump includes the following steps:

[0073] 1) Drawing software to draw 3D model

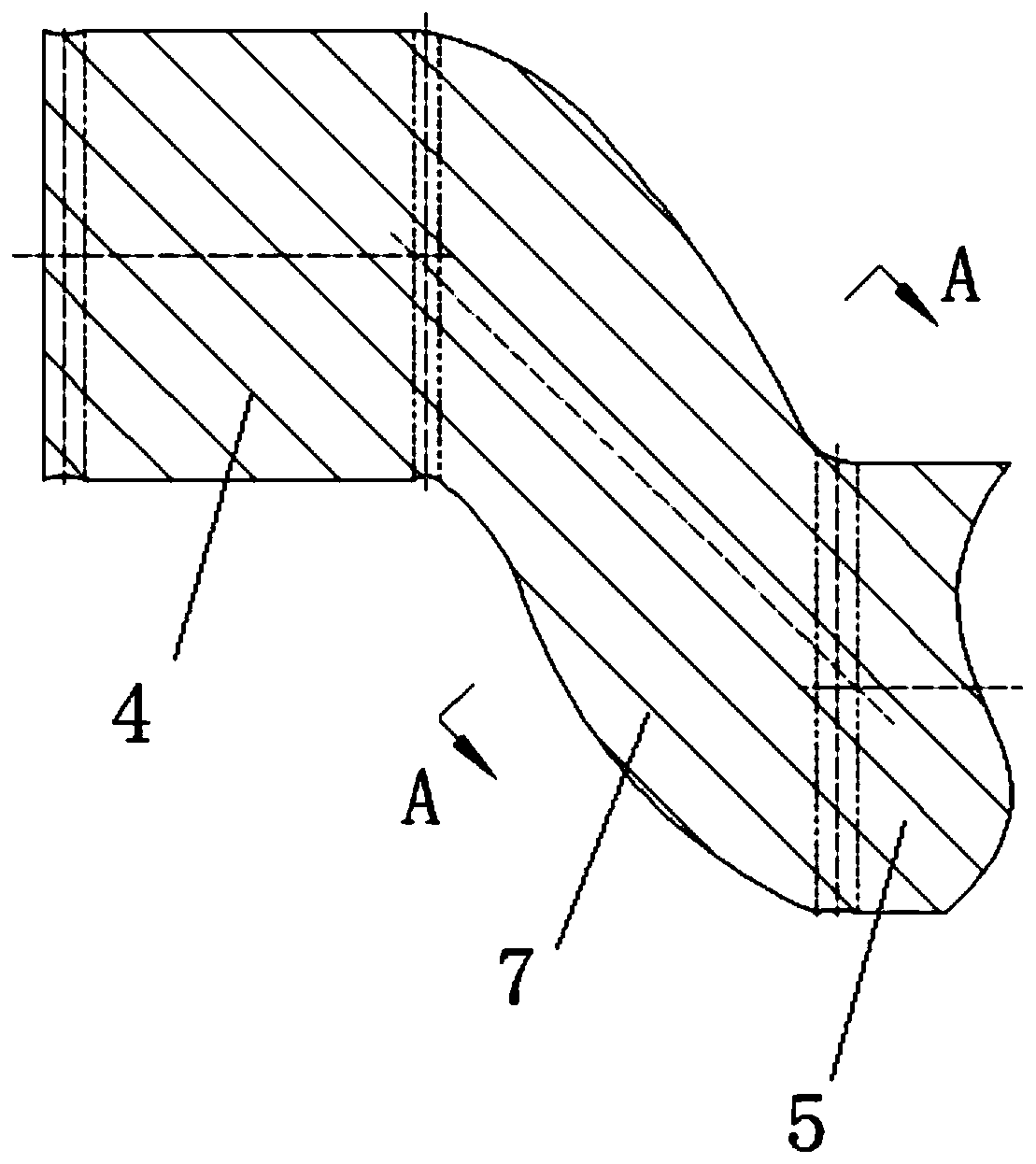

[0074] 1.1) design the crankshaft, and draw the crankshaft 9 three-dimensional models in the drawing software, and set it to an opaque state, and the color is set as the first light color; wherein, the drawing software is solidworks; the inner surface of the three-dimensional bearing simulation ring 10 is a conical surface, The taper of the cone surface is 1:12.

[0075] 1.2) Draw a three-dimensional bearing simulation ring 10, whose structural size is the same as that of the bearing to be installed, and the inner surface of the three-dimensional bearing simulation ring 10 is a conical surface; and set it to a light-colored translucent state, and set the color to the second light color; After the first light color and the second light color are clearly distinguishe

Embodiment 2

[0088] Such as Figure 17 to Figure 19 As shown, a simulated installation method of a three-cylinder crankshaft bearing of a diaphragm pump includes the following steps:

[0089] 1) Drawing software to draw two-dimensional model

[0090] 1.1) Design the crankshaft, and draw multiple contours of the crankshaft at different rotation angles according to the design size, and set each contour as a thick solid line;

[0091] 1.2) Draw a two-dimensional bearing simulation ring 10, whose outline size is the same as that of the bearing to be installed, and set it as a dotted line; the thick solid line and the dotted line are clearly distinguished, and a linear intersection 11 appears after overlapping;

[0092] 2) Simulated installation of bearings

[0093] Each profile of the crankshaft 9 and the two-dimensional bearing simulation ring 10 are displayed on the screen, so that the two-dimensional bearing simulation ring 10 passes through the crankshaft 9 from one end of the crankshaft 9

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap