Environment-friendly pervious concrete and preparation method thereof

A permeable concrete and environment-friendly technology, applied in the field of building materials, can solve the problems of insufficient research on the design method of permeable concrete mix ratio and molding process, and achieve the effect of improving construction performance and mechanical properties, increasing strength, and expanding bonding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

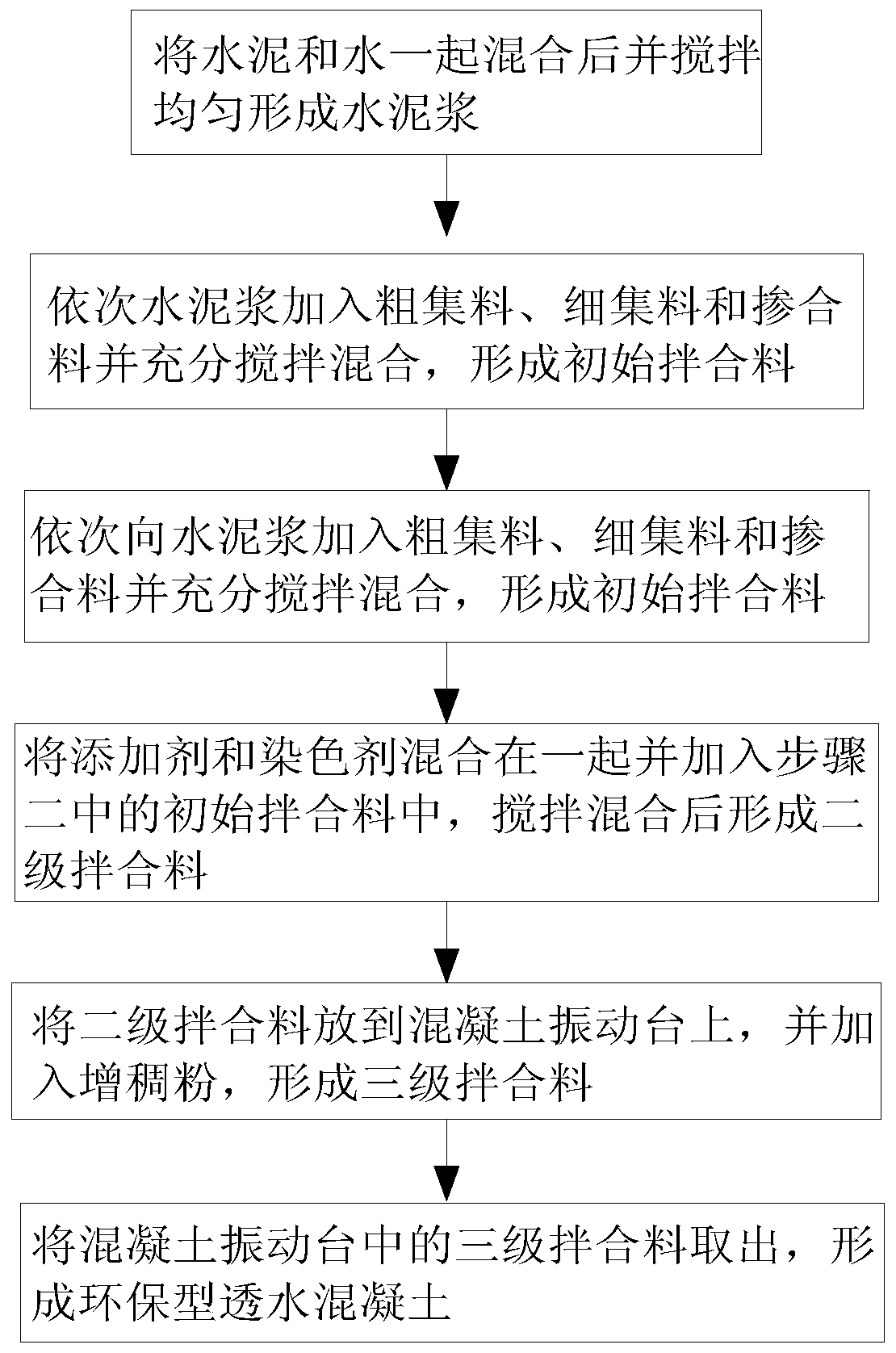

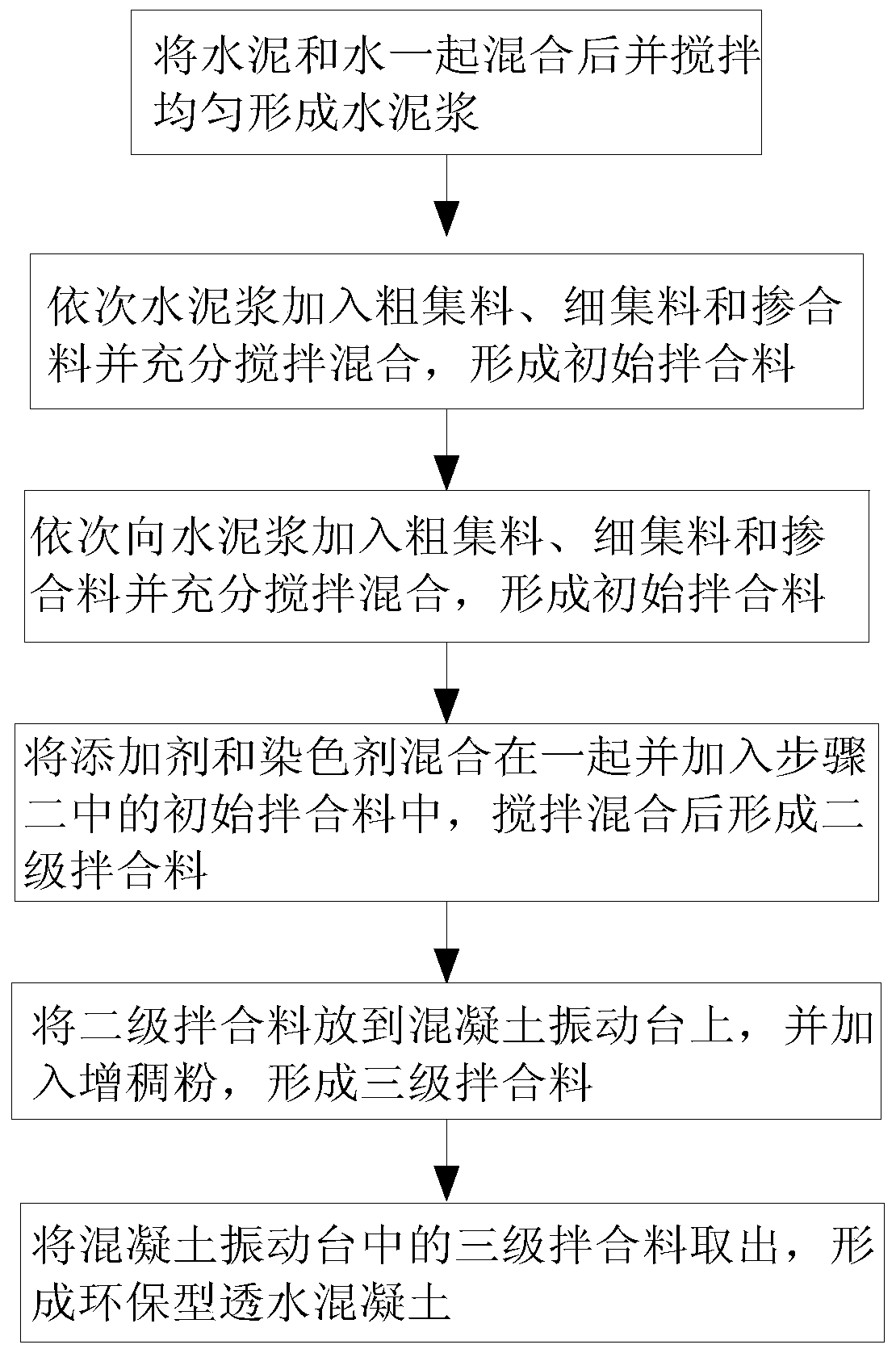

[0026] like figure 1 As shown, an environmentally friendly permeable concrete is prepared from the following raw material components in parts by weight: 100 parts of cement, 200 parts of water, 80 parts of coarse aggregate, 50 parts of fine aggregate, 20 parts of admixture, 10 parts of additives, 10 parts of coloring agent and 5 parts of thickening powder.

[0027] The cement is low-alkali cement; the coarse aggregate is crushed stone of 5 mm; the fine aggregate is crushed stone below 5 mm; the admixture is one of slag powder and fly ash; The additive is a mixture of air-entraining agent and quick-setting agent; the coloring agent is iron oxide; and the thickening powder contains rubber powder.

[0028] A preparation method of environment-friendly permeable concrete, comprising the steps of:

[0029] Step 1: Mix cement and water together and stir evenly to form cement slurry;

[0030] Step 2: adding coarse aggregate, fine aggregate and admixture to the cement slurry in step 1

Embodiment 2

[0041] like figure 1 As shown, an environment-friendly permeable concrete is prepared from the following raw material components in parts by weight: 125 parts of cement, 225 parts of water, 85 parts of coarse aggregate, 60 parts of fine aggregate, 25 parts of admixture, 15 parts of additives, 15 parts of coloring agent and 8 parts of thickening powder.

[0042] The cement is low-alkali cement; the coarse aggregate is crushed stone of 8mm; the fine aggregate is crushed stone below 3mm; the admixture is one of slag powder and fly ash; The additive is a mixture of air-entraining agent and quick-setting agent; the coloring agent is iron oxide; and the thickening powder contains rubber powder.

[0043] A preparation method of environment-friendly permeable concrete, comprising the steps of:

[0044] Step 1: Mix cement and water together and stir evenly to form cement slurry;

[0045] Step 2: adding coarse aggregate, fine aggregate and admixture to the cement slurry in step 1 in seq

Embodiment 3

[0056] like figure 1 As shown, an environmentally friendly permeable concrete is prepared from the following raw material components in parts by weight: 150 parts of cement, 250 parts of water, 90 parts of coarse aggregate, 70 parts of fine aggregate, 30 parts of admixture, 20 parts of additives, 20 parts of coloring agent and 10 parts of thickening powder.

[0057] The cement is low-alkali cement; the coarse aggregate is crushed stone of 10 mm; the fine aggregate is crushed stone below 4 mm; the admixture is one of slag powder and fly ash; The additive is a mixture of air-entraining agent and quick-setting agent; the coloring agent is iron oxide; and the thickening powder contains rubber powder.

[0058] A preparation method of environment-friendly permeable concrete, comprising the steps of:

[0059] Step 1: Mix cement and water together and stir evenly to form cement slurry;

[0060] Step 2: adding coarse aggregate, fine aggregate and admixture to the cement slurry in step

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap