Handheld dust prevention type cutting device used in assembly type CF plate installation

A technology of cutting device and dust-proof device, which is applied in metal processing and other directions, can solve the problems affecting the health of workers, poor molding quality, lack of dust-proof settings, etc., to ensure the health of the body, ensure the quality of molding, and avoid polluting the environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

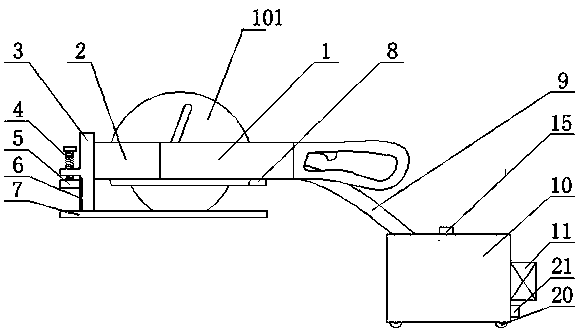

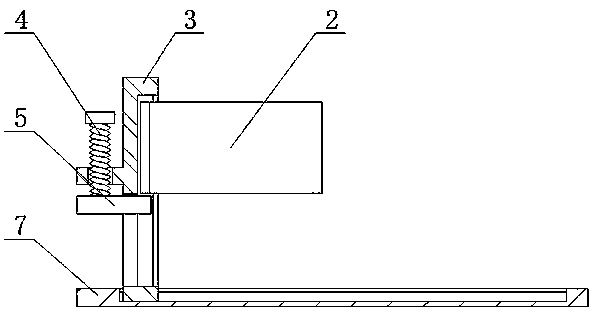

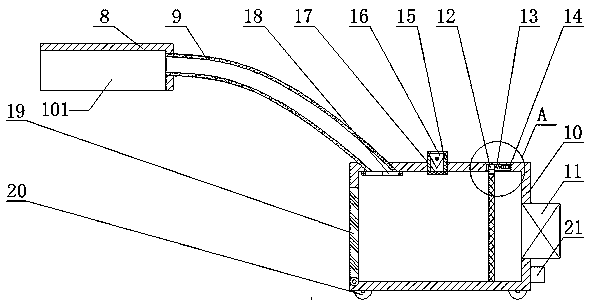

[0023] Such as Figure 1-5 As shown, a hand-held dust-proof cutting device in an assembled CF board installation includes a hand-held cutting body, a fixed block 2 and a dust-proof device. The hand-held cutting body is detachably connected to the right end of the fixed block 2, and the detachable The connection can be realized by bolts or sleeves. The left end of the fixed block 2 is provided with a bracket 3. The fixed block 2 is set on the upper part of the bracket 3 and is slidably connected with the bracket 3. The bracket 3 is also equipped with a threaded shaft threaded with the bracket 3. 4. The bottom end of the threaded shaft 4 is equipped with a slider 5. The slider 5 is set on the lower part of the bracket 3 and is slidingly connected with the bracket 3. The rotation of the threaded shaft 4 drives the slider 5 to move up and down, and t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap