Air-resistance type sealing structure and working method

A technology of sealing structure and working method, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of large leakage between dynamic and static gaps, achieve the effects of enhancing energy dissipation, reducing gap leakage, and improving safety and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

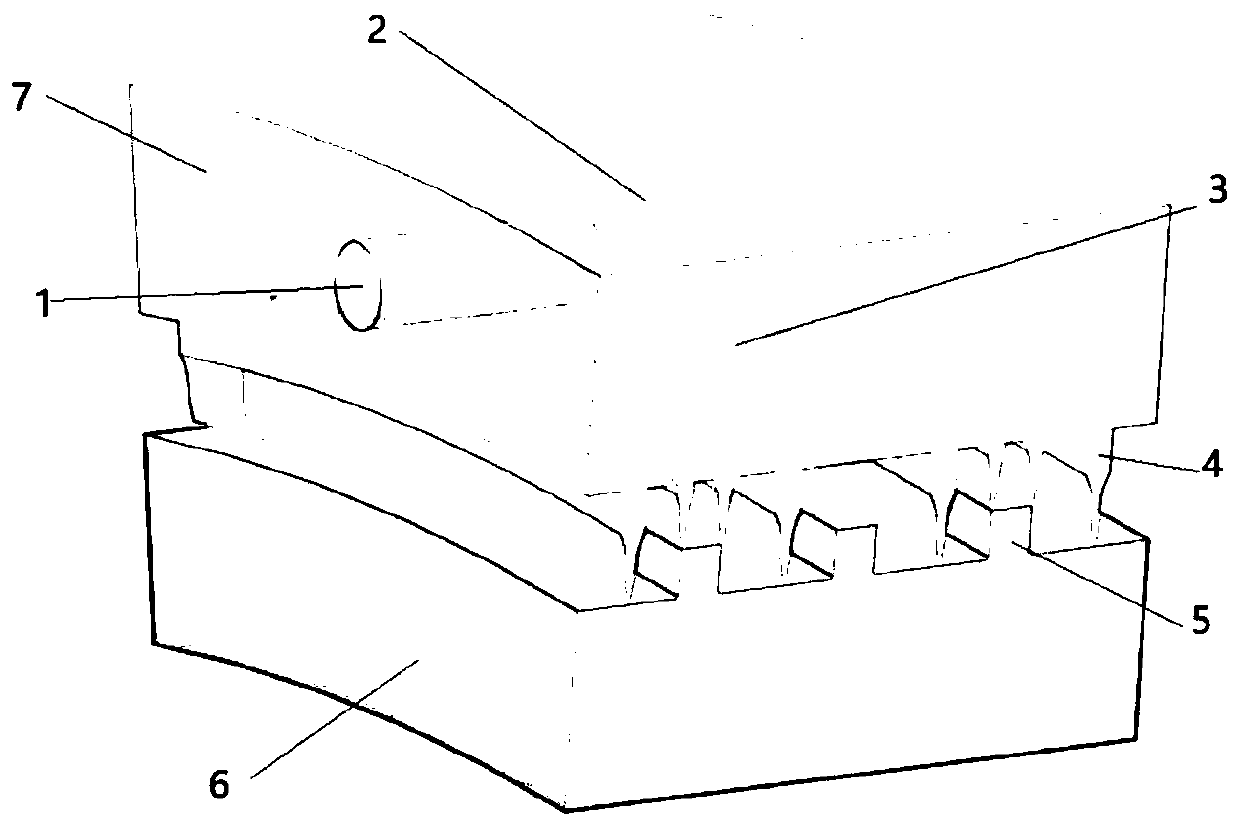

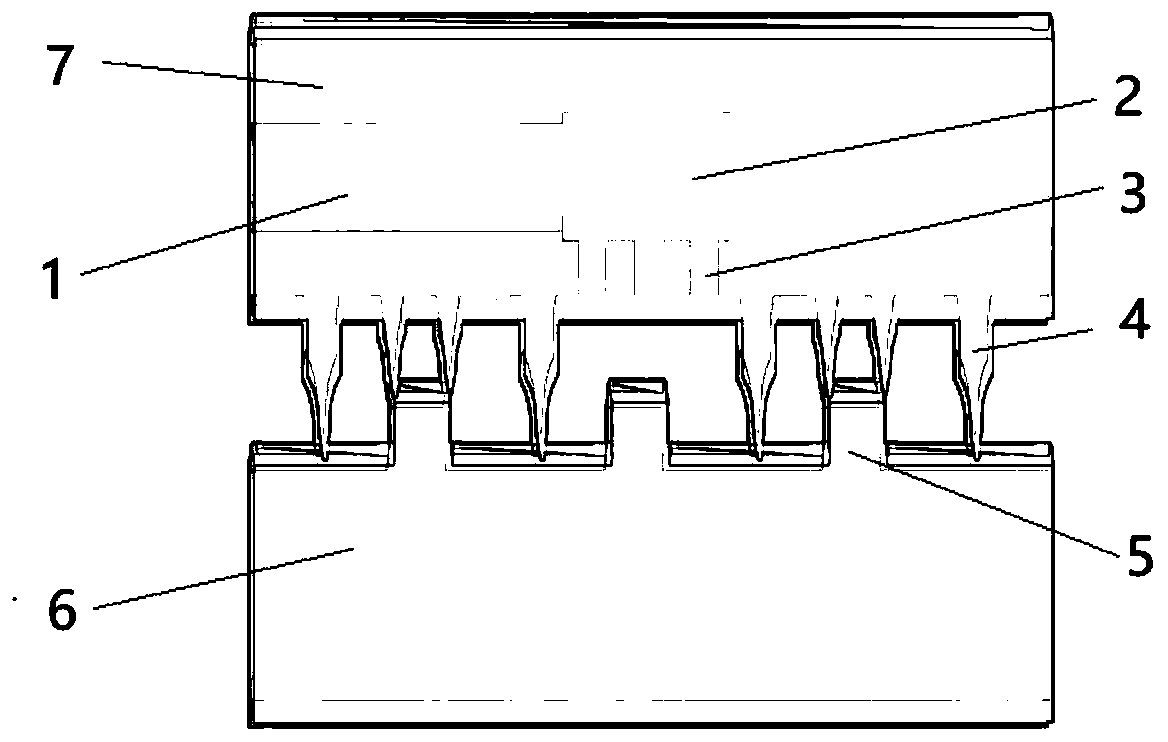

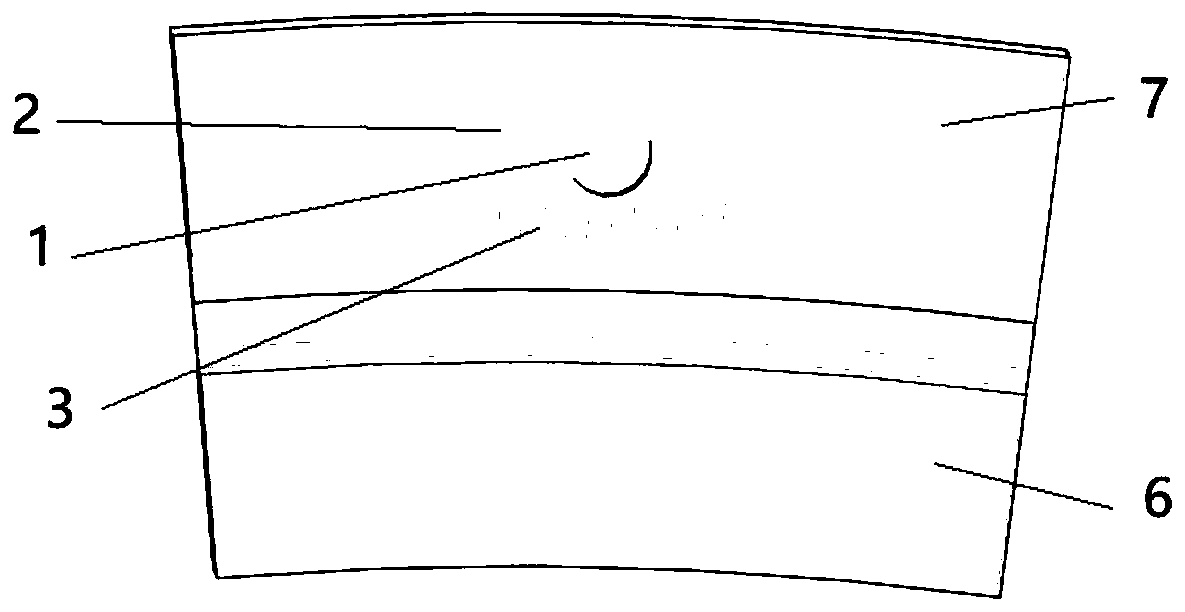

[0025] see Figure 1 to Figure 4 , an air resistance type sealing structure, including a rotor 6 and a stator block 7, the stator block 7 is set outside the rotor 6, the rotor 6 is provided with a boss 5, and the stator block 7 is provided with a seal matching the boss 5 Teeth 4, sealing teeth 4 cooperate with the boss 5 to form a labyrinth seal, the stator block 7 is built with a pressure equalization slow flow chamber 2, and the pressure equalization slow flow chamber 2 communicates with the outside world through the high pressure drainage tube 1, and the high pressure drainage tube 1 flows from the The end face of the stator block 7 communicates with the outside world. The pressure-equalizing slow flow chamber 2 is connected with a number of inner chamber pressure air guide tubes 3 , and all the inner cavity pressure air guide tubes 3 face the boss 5 on the stator bloc

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap