Filtering protection structure for ophthalmic laser operation

A protective structure and ophthalmic laser technology, applied in the field of medical surgical instruments, can solve the problems of poor adjustment effect of filter flexibility, poor surgical sight of operators, and inability to replace the filter, so as to meet the needs of protective use and ensure stability , the effect of lengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

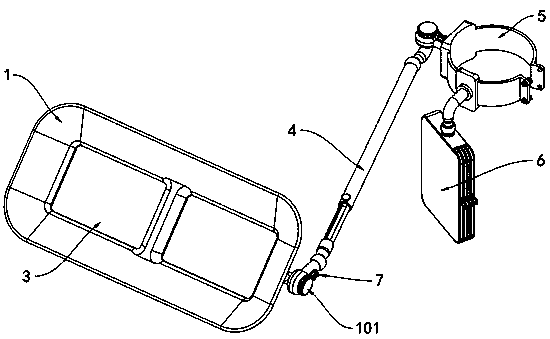

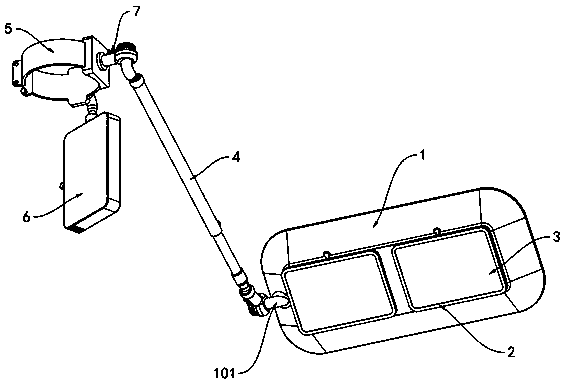

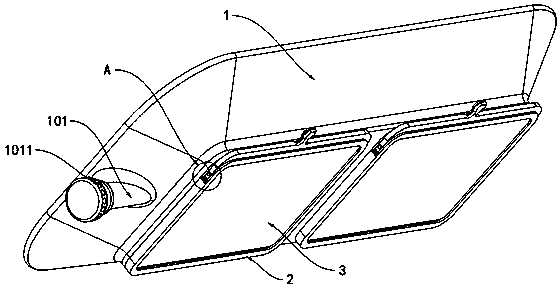

[0036] as attached figure 1 to attach Figure 12 Shown:

[0037]The invention provides a filter protection structure for ophthalmic laser surgery, comprising a light-shielding protective plate frame 1, an assembly frame 2, a light filter plate 3, an adjustment connecting rod 4, a storage box 6 and a limit mechanism 7; the light-shielding protective plate There is a connecting shaft 101 at the right end of the frame 1, and sixteen limiting shaft grooves 1011 are provided on the outside of the connecting shaft 101 in a circular shape; the assembly frame 2 is a square frame structure, and there are two in total, and the two assembly frames 2 are left and right Symmetrically installed on the outside of the light-shielding protective plate frame 1; the light filter plate 3 is a square sheet structure, and the light filter plate 3 is located inside the assembly frame 2; 5 are connected, and the outside of the rear connector 403 provided with the rear end of the adjusting link 4 is su

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap