Method for improving appearance attractiveness of wooden furniture

A technology for wooden furniture and aesthetics. It is applied in the direction of wood processing appliances, wooden veneer joints, and manufacturing tools. It can solve problems such as poor smoothness and flatness, poor film quality, and surface film wrinkles. Achieve the effect of improving the appearance aesthetics, improving the effect and quality, and improving the wrinkles of the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

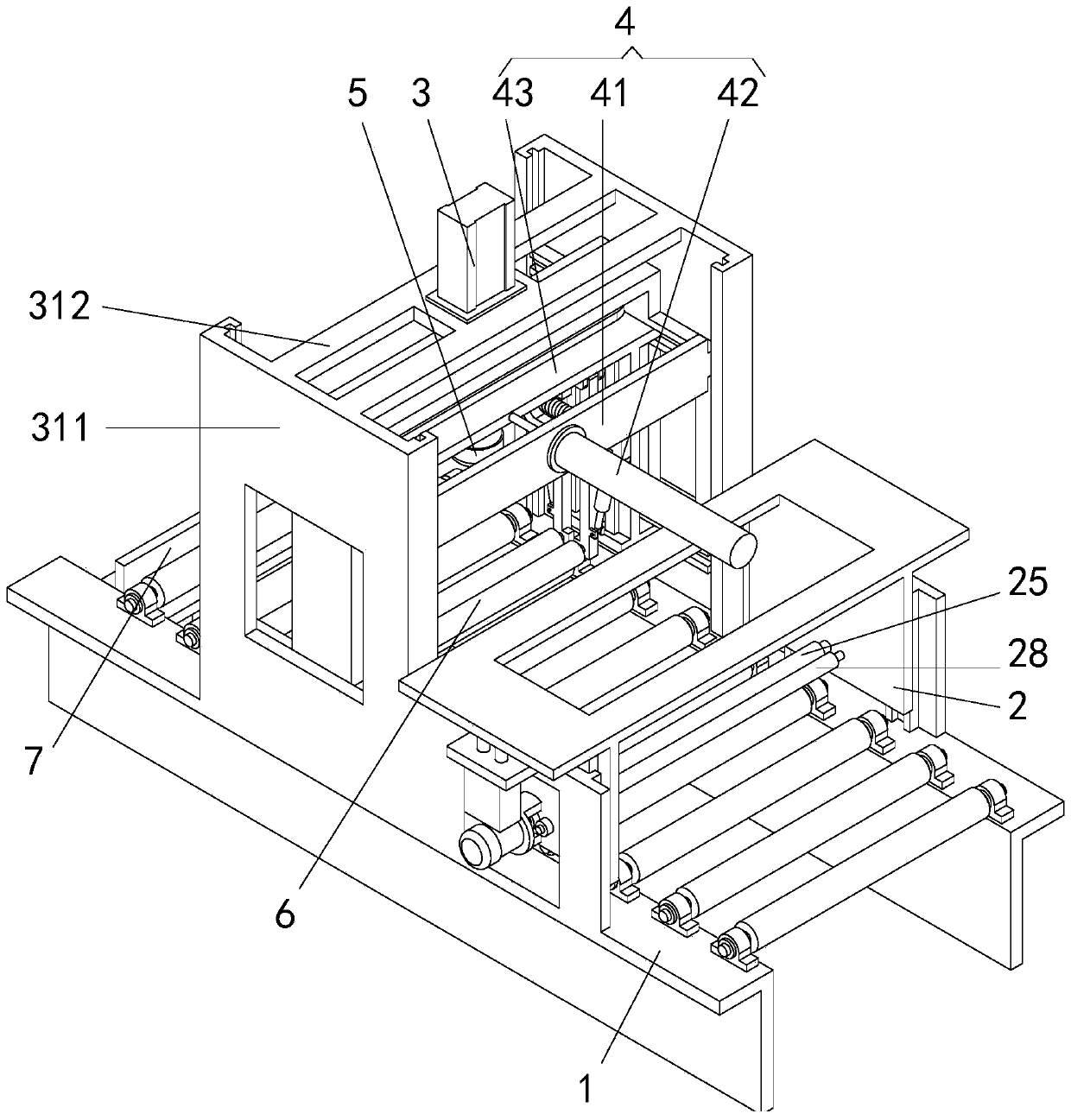

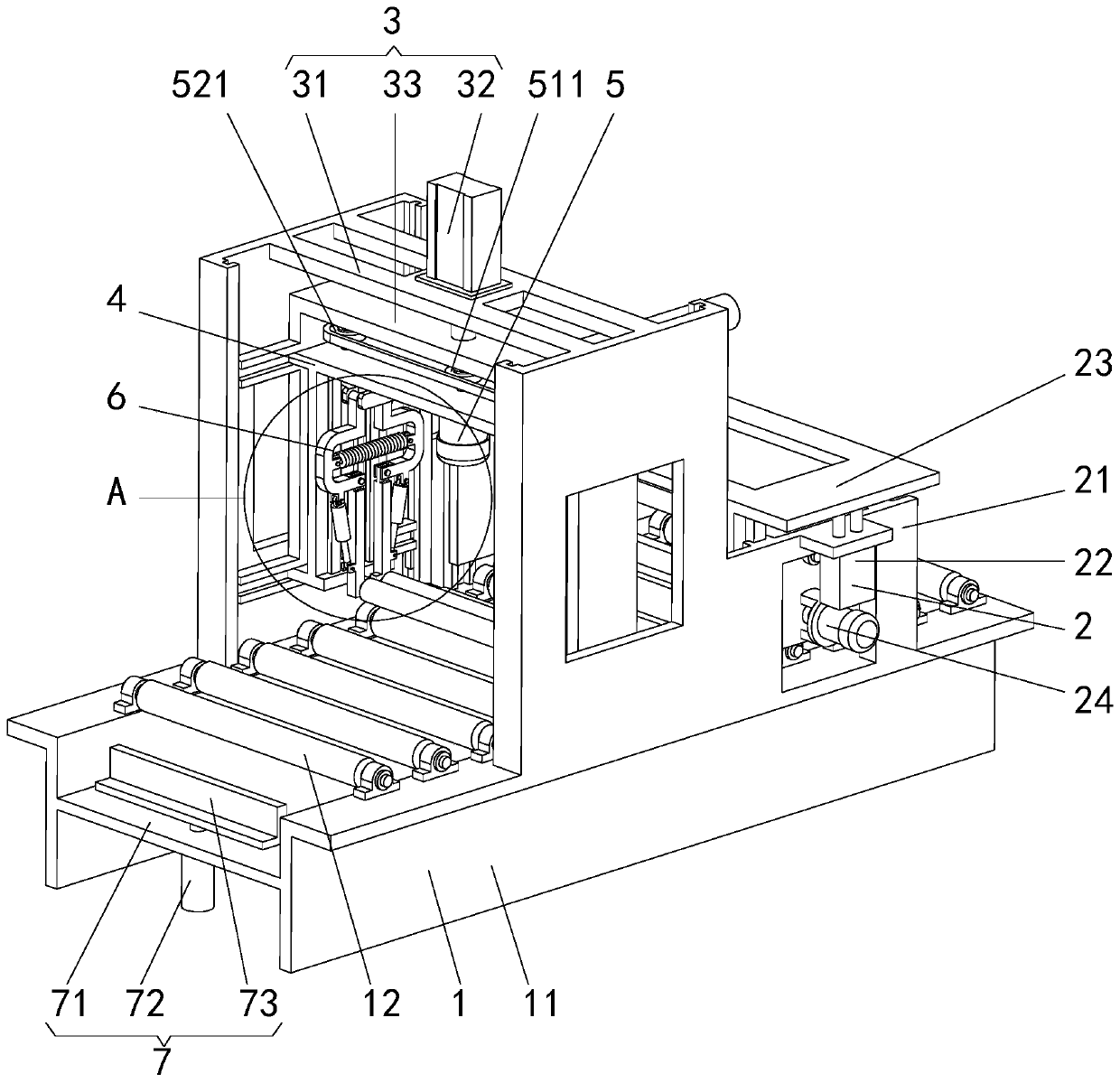

[0038] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and To facilitate its practice, but not as a limitation of the invention.

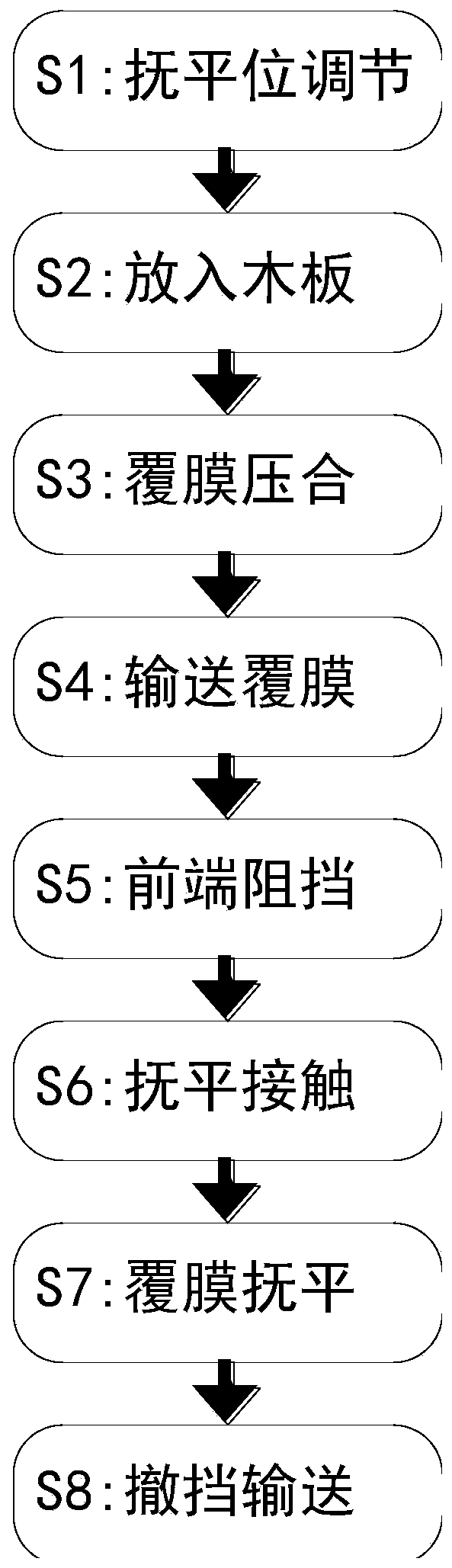

[0039] See attached Figure 1-10 As shown, a method for improving the appearance aesthetics of wooden furniture, the method specifically includes the following steps:

[0040] S1. Smoothing position adjustment: the horizontal adjustment mechanism 4 drives the smoothing actuator 6 to move horizontally, so as to adjust the initial position of the smoothing roller 63, so as to adapt to the smoothing operation after the wood board of a specific width is covered with film;

[0041] S2. Putting in the wooden board: put the wooden board pre-coated with film glue on the r

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap