Slice-type temperature sensor

A technology of temperature sensor and sheet, used in thermometers, thermometers and instruments based on the expansion/contraction of materials, etc., can solve the problem of not being able to continue to respond to temperature changes, and improve the scope of application, increase the control range, bend The effect of expanding the arc angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

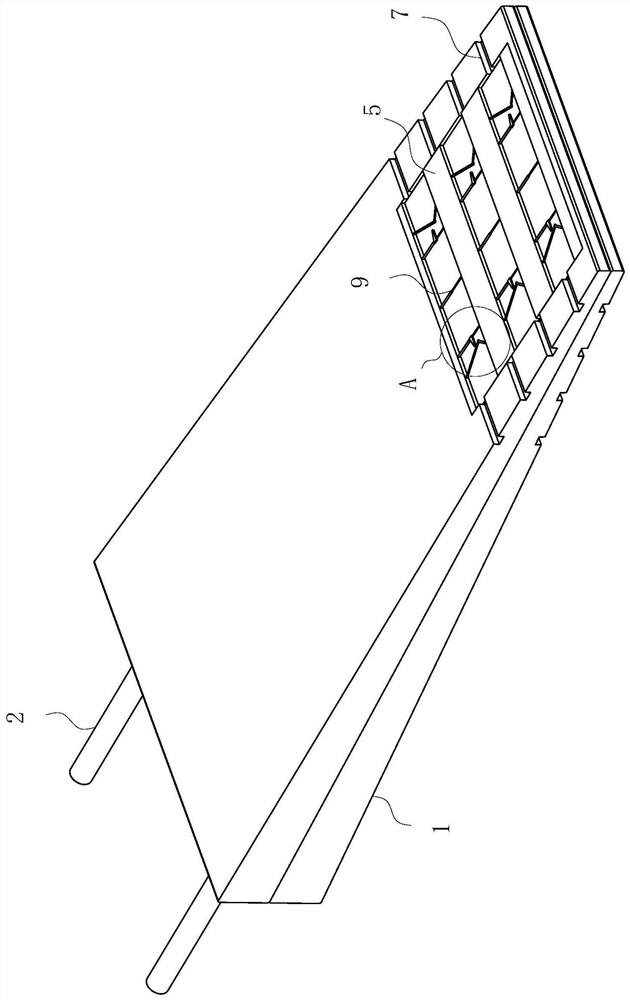

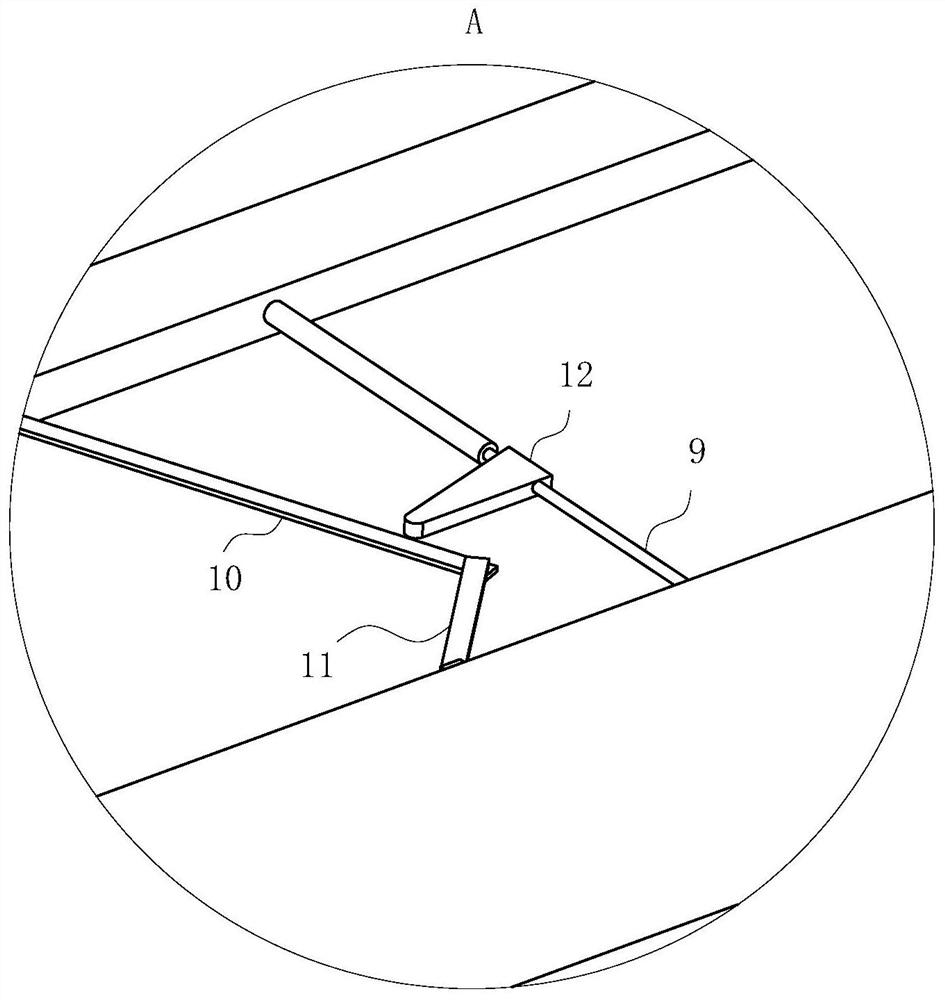

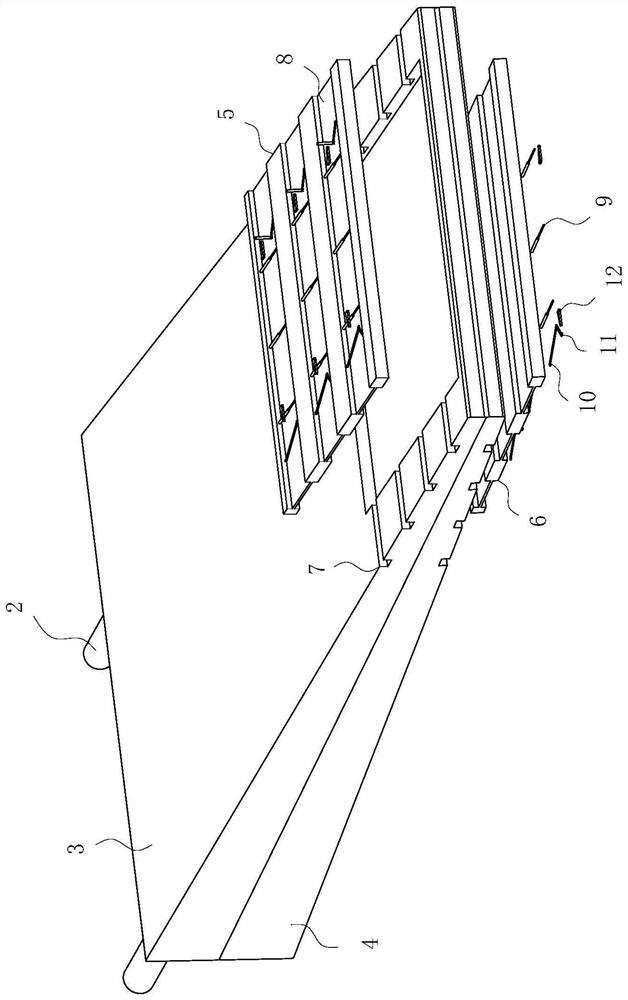

[0038] As a specific embodiment of the present invention, the thickness value of the No. 3 metal sheet 5 is greater than the thickness value of the No. 4 metal sheet 6; during work, the thickness value of the No. 3 metal sheet 5 is greater than the thickness value of the No. 4 metal sheet 6 The degree of thermal expansion of the No. 3 metal piece 5 is greater, so that the degree of deformation of the sensor is greater, thereby improving the measurement accuracy of the sensor.

[0039]When working, the existing bimetal 1 temperature sensor can only perform a single closing and separation, and cannot continue to respond to the continuous change of temperature after closing, so that the use of the bimetal 1 temperature sensor has limitations. The invention solves this problem; by being respectively provided with the No. 3 metal sheet 5 and the No. 4 metal sheet 6 on both sides of the bimetal 1, when the bimetal 1 is heated, the No. 3 metal sheet 5 and the No. 4 metal sheet 6 are all

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap