Railway retarder large-scale on-line monitoring device and method based on fiber bragg grating

A fiber grating and monitoring device technology, which is applied in the direction of railway vehicle shape measuring devices, railway car body parts, railway auxiliary equipment, etc., can solve the problems of inability to meet the requirements of station detection, low efficiency of deceleration jacks, and inability to accurately judge the state of deceleration jacks and other issues, to achieve low-cost large-scale deployment, improve safety, and reduce labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below with reference to the accompanying drawings, through the description of the embodiments, the specific implementation of the present invention, such as the shape and structure of each component involved, the mutual position and connection relationship between each part, the function and working principle of each part, and the manufacturing process and operation and use methods, etc., are described in further detail to help those skilled in the art to have a more complete, accurate and in-depth understanding of the inventive concept and technical solutions of the present invention.

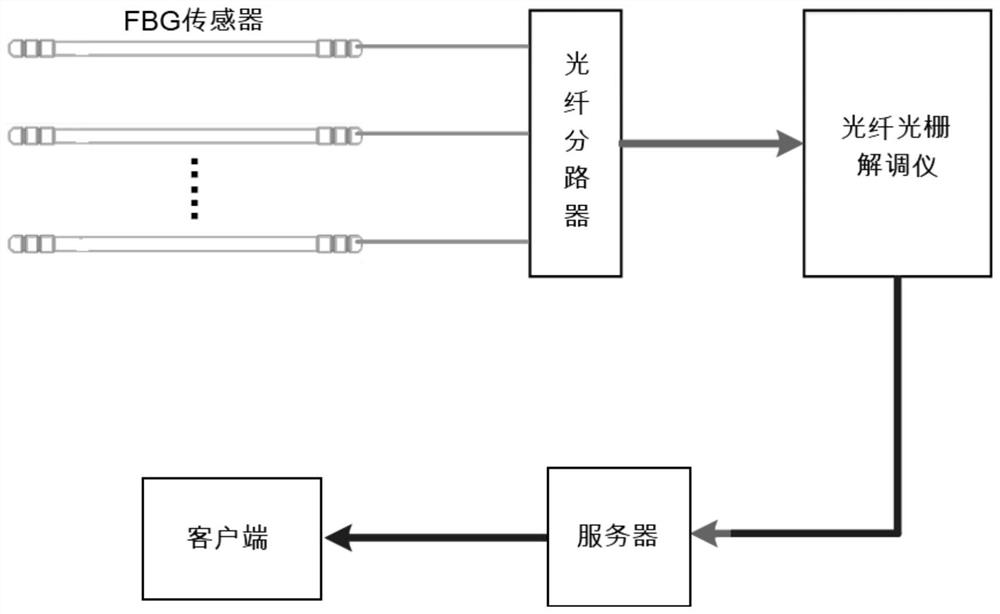

[0032] The large-scale online monitoring equipment for railway deceleration roof based on fiber grating includes fiber Bragg grating sensor (FBG sensor), fiber splitter, fiber grating demodulator, server and client.

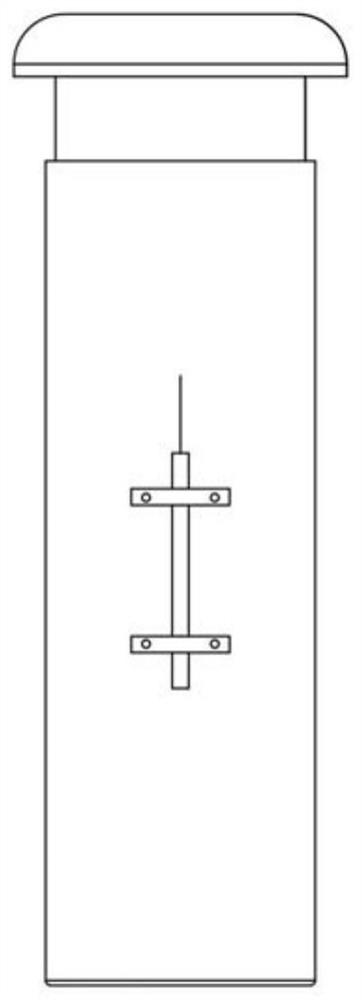

[0033] The FBG sensor is installed on the ordinary speed reducer. A single FBG sensor has a specific value of the center wavelength, which can convert the change of the force

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap