Prediction method for horizontal deformation of high-core-wall rock-fill dam in construction period

A technology of horizontal deformation and prediction method, applied in the direction of measuring devices, instruments, electrical digital data processing, etc., can solve the problems of poor prediction accuracy of physical causes, deformation of deformation monitoring points, etc., and achieve high deformation prediction accuracy, good simulation and reflected effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention are described below so that those skilled in the art can understand the present invention, but it should be clear that the present invention is not limited to the scope of the specific embodiments. For those of ordinary skill in the art, as long as various changes Within the spirit and scope of the present invention defined and determined by the appended claims, these changes are obvious, and all inventions and creations using the concept of the present invention are included in the protection list.

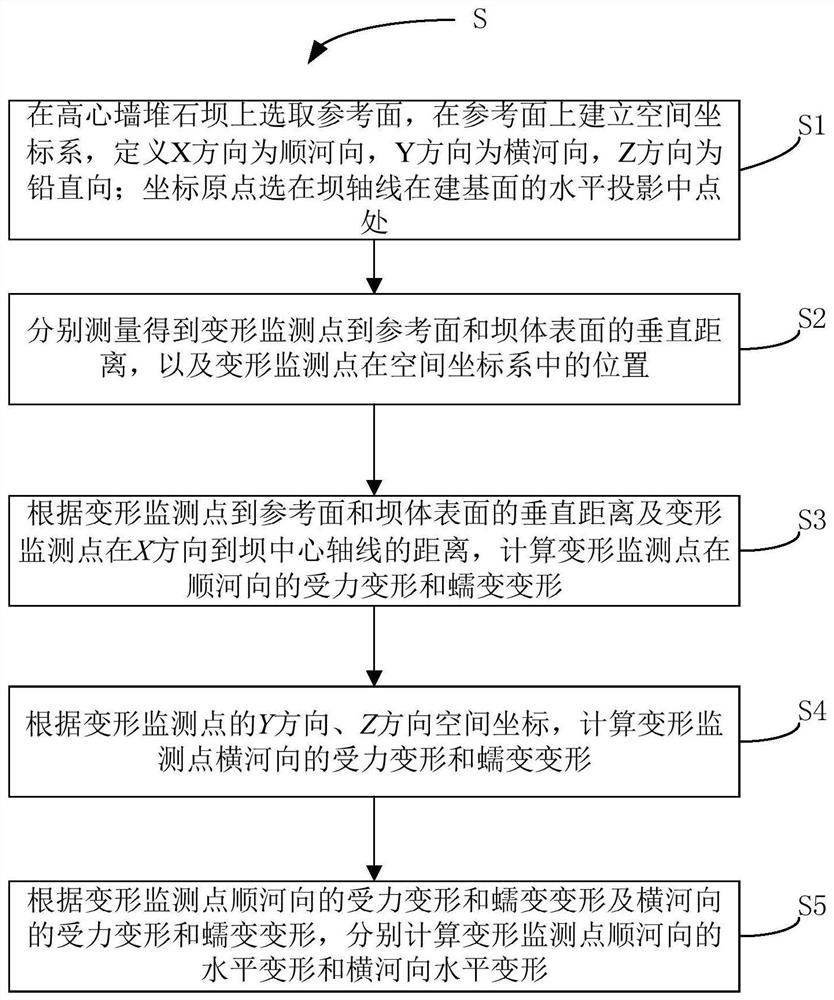

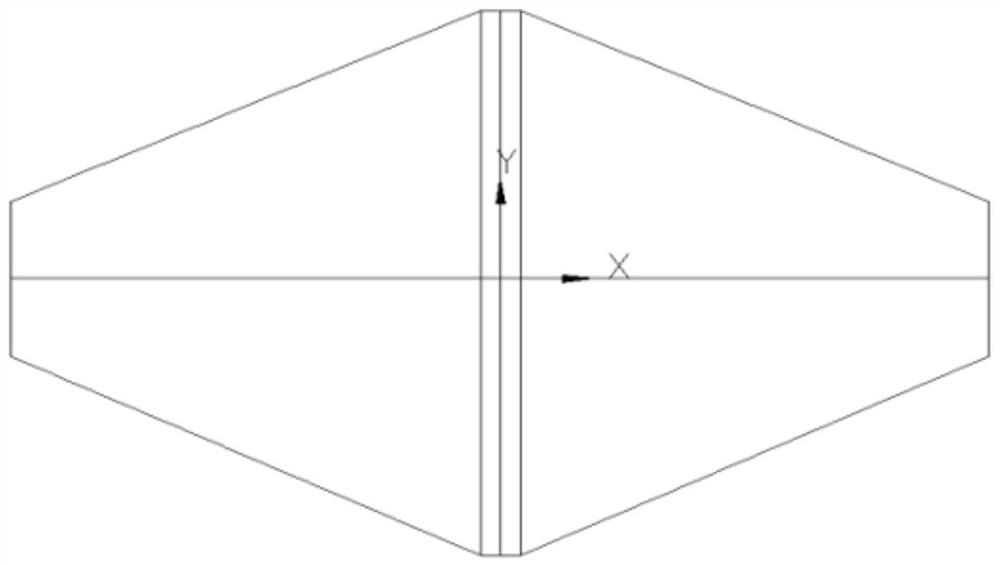

[0026] refer to figure 1 , figure 1 A method for predicting horizontal deformation of a high-core rockfill dam during construction is shown; the method S includes steps S1 to S6.

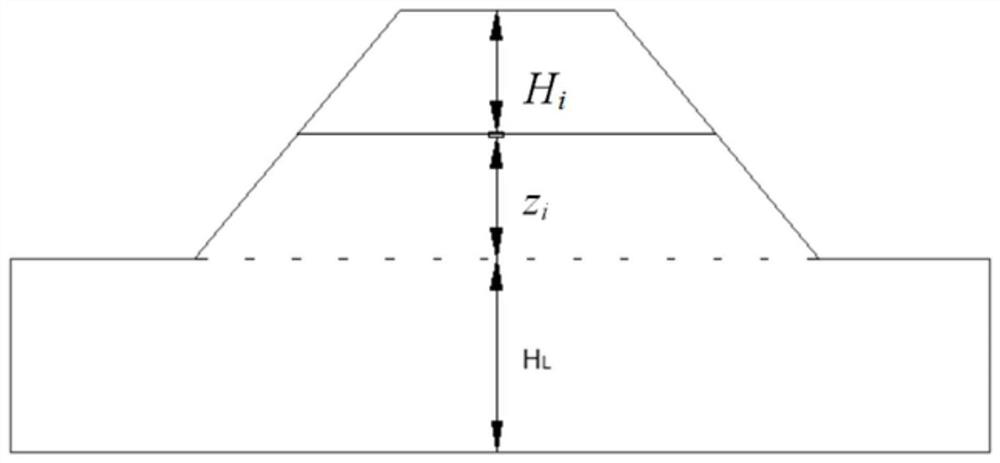

[0027] In step S1, a reference surface is selected on the high-core rockfill dam, and the distance from each monitoring point to the reference surface is determined according to the horizontal deformation monitoring points and their positions arran

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap