Secondary impact preventing device of drop hammer impact testing machine and testing method of secondary impact preventing device

A technology of drop weight impact test and secondary impact, which is applied in the field of drop weight impact test equipment and anti-secondary impact device of drop weight impact testing machine, which can solve the problems of inability to maintain experimental accuracy, secondary impact damage of specimens, and too late Push out and other issues to achieve the effect of easy experimental mechanism, accurate capture, and avoidance of further damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

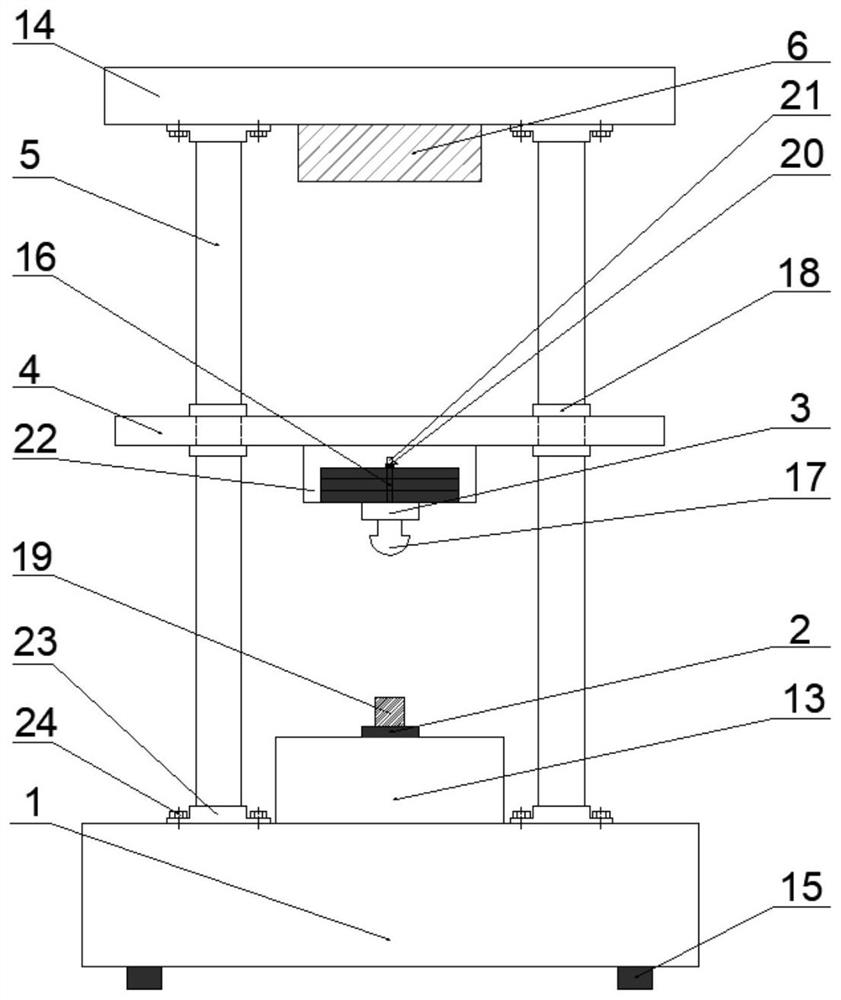

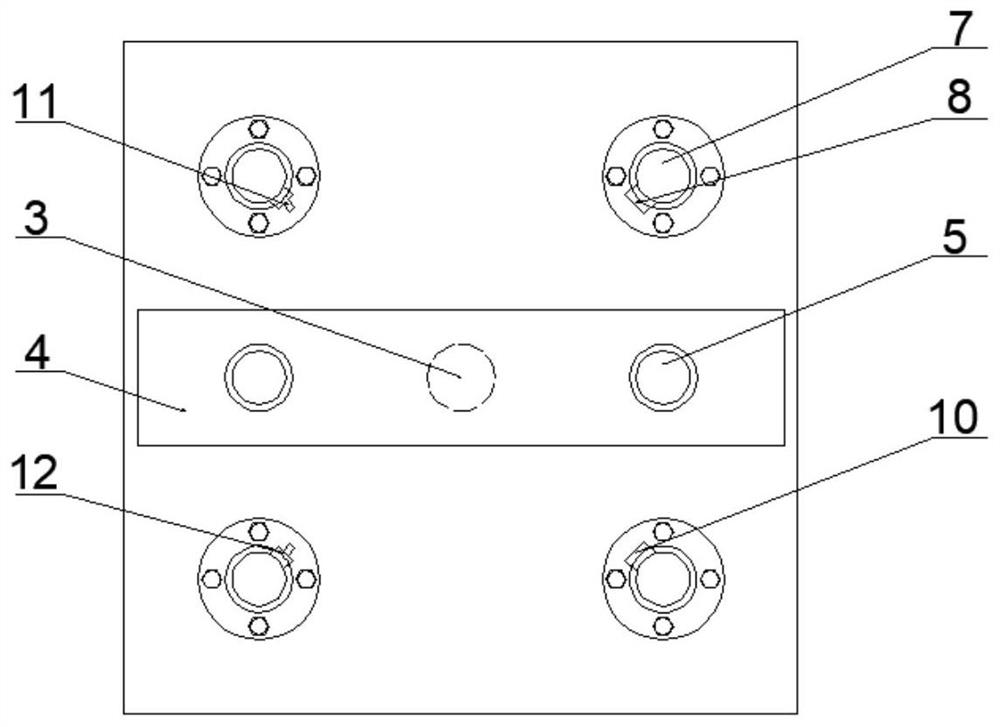

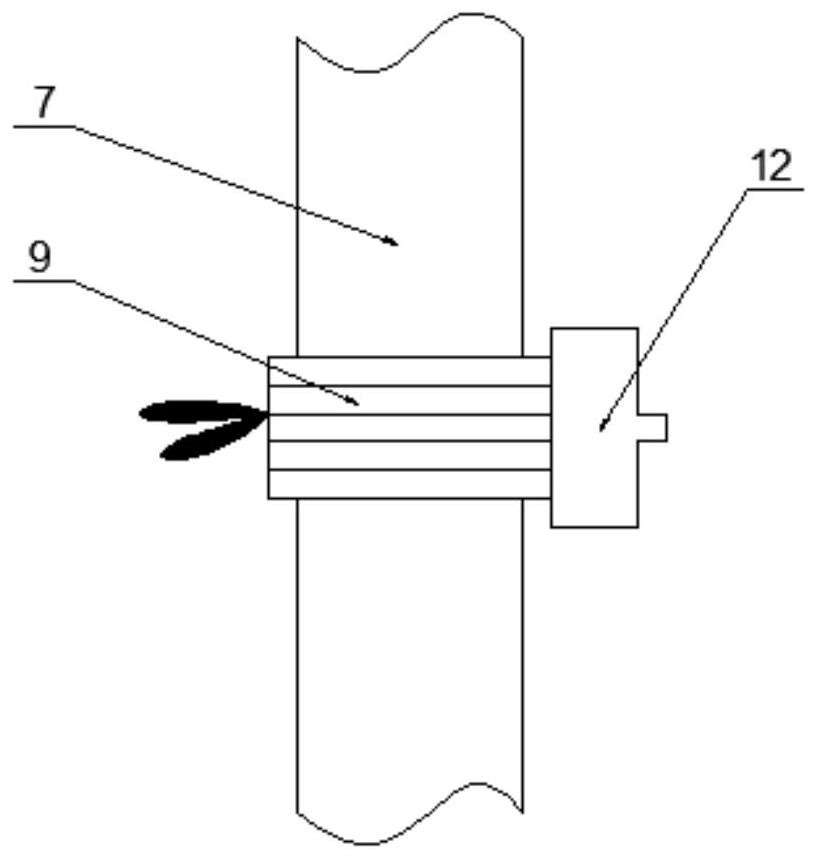

[0028]Example 1: Such asFigure 1-4As shown, a secondary impact prevention device for a drop hammer impact testing machine includes a top plate 14, a base 1, a support rod 7, a guide rod 5, a sliding plate 4, and a controller. A stage 13 is installed on the base 1, and the load The pad 2 is installed on the table 13 and the sample 19 is placed on the pad 2; support rods 7 are installed around the upper part of the base 1, the top of the support rod 7 is connected with the top plate 14, and the guide rod 5 is installed in the middle of the two support rods 7 on the left and right sides to guide The bottom of the rod 5 is connected with the base 1 and the top is connected with the top plate 14. The sliding plate 4 is installed on the two guide rods 5, the sliding plate 4 is installed with a counterweight chamber 22, and the counterweight chamber 22 is installed with a counterweight plate 16 under the counterweight chamber 22 Install the hammer head base 3, install the drop hammer 17 under

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap